Preparation method of copper-matrix aluminum oxide nano material

A nano-alumina and copper-based technology, which is applied in the field of copper-based composite material preparation, can solve the problems of long process flow, uneven distribution of alumina, and low performance of nanomaterials, achieving shortened process flow, low cost, and guaranteed uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

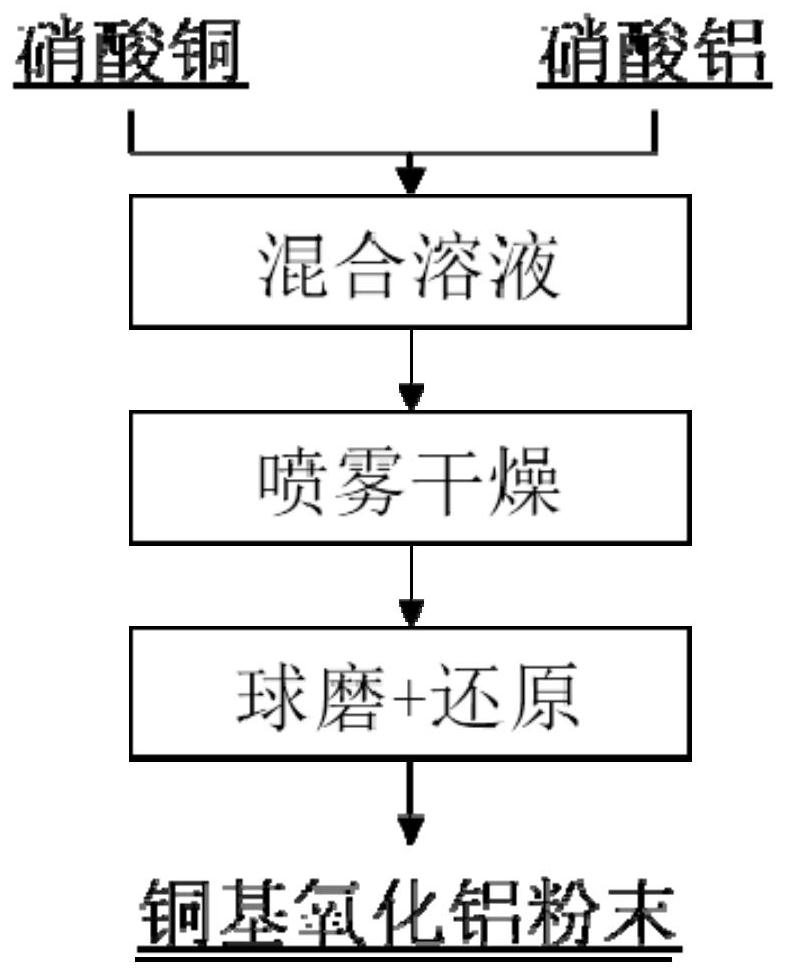

[0036] figure 1 The process flow of the preparation method of copper-based alumina nanomaterials in the embodiment of the present invention is schematically shown. like figure 1 As shown, in an optional embodiment, a method for preparing a copper-based alumina nanomaterial provided by the present invention may include:

[0037] Step S1, to analyze pure Cu(NO 3 ) 2 ·3H 2 O(or Cu(NO 3 ) 2 ·6H 2 O) and Al(NO 3 ) 3 9H 2 O is the raw material, according to the Al in copper-based alumina nanopowder 2 o 3 The mass fraction is 0.1-5wt%, and the proportion of copper nitrate and aluminum nitrate is configured. Preferably according to Al 2 o 3 The copper-based aluminum oxide nanometer powder is configured with a mass fraction ranging from 0.7 to 1.5 wt%.

[0038] In the step of the present invention, analytically pure copper nitrate and aluminum nitrate are selected as raw materials and dissolved in water to ensure sufficient mutual solubility of the two raw materials. Ab...

Embodiment 1-3

[0053] Embodiment 1-3 is based on Cu(NO 3 ) 2 ·3H 2 O and Al(NO 3 ) 3 9H 2 O is raw material; Embodiment 4-6 is based on Cu(NO 3 ) 2 ·6H 2 O and Al(NO 3 ) 3 9H 2 O is the raw material. In the following examples 1-6, the detection standard of copper-based alumina nano-powder is: (1) Density measurement: GB / T5162-2006; (2) Conductivity: the powder is pressed into tablets, and measured by four-probe method Conductivity; (3) hardness: measured by nano-micromechanical probe; (4) powder particle size: electron microscope method, laser particle size analysis method, X-ray diffraction method, etc. can be used, and the powder in Examples 1-6 of the present invention The particle size was measured by electron microscopy.

Embodiment 1

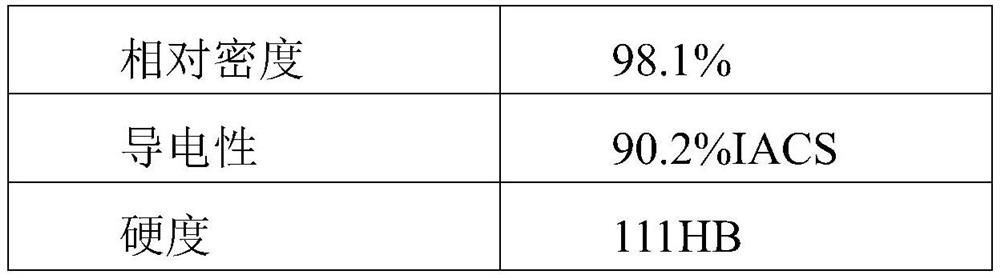

[0055] According to the mass fraction of alumina in the copper-based alumina composite material being 1%, the copper nitrate solution and the aluminum nitrate solution are prepared. The mixed solution was prepared into precursor powder by using a spray dryer. The precursor powder was placed in a heatable and ventilated planetary ball mill, and ball milled for 10 h under the conditions of 600 ° C, ball mill speed 500 rpm, and hydrogen (1 L / min) to prepare copper-based alumina nanopowder. After testing, the main physical parameters of the copper-based alumina nanopowder are shown in Table 1.

[0056] Table 1 Physical parameters of copper-based alumina nanopowder

[0057] Relative density 98.3% Conductivity 90.8%IACS hardness 113HB Powder particle size 28nm

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com