Carboxylation modified nano titanium dioxide ultraviolet screening agent and preparation method thereof

A technology of nano-titanium dioxide and ultraviolet shielding agent, which is applied in the direction of titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve the problems of affecting the reactivity of nano-TiO, consuming acrylic acid, etc., to improve the ultraviolet shielding performance and reduce agglomeration , The effect of enhancing light absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

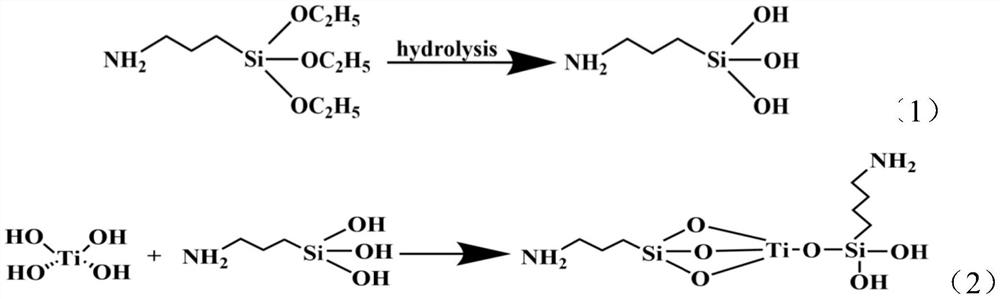

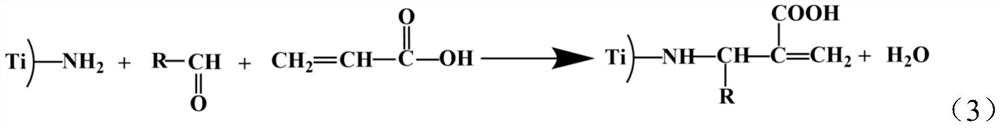

[0038] Carboxylation modified nano-TiO of the present invention 2 The preparation method of the ultraviolet shielding agent comprises the following steps: according to the mass fraction, 8-10 parts of TiO 2 -NH 2 Add to 100-120 parts of absolute ethanol, ultrasonically disperse for 30 minutes, pour the suspension into a three-necked flask, stir and heat up to 60°C, with a rotation speed of 400r / min, add 4-8 parts of aldehydes and 3-5 parts Acrylic acid, 60°C magnetic stirring reaction for 5h, cooling the product, centrifuging to remove the supernatant, washing the white precipitate in the lower layer with alcohol, drying in a vacuum oven at 40°C for 5h to obtain carboxylated modified nano-TiO 2 UV screener. Among them, TiO 2 -NH 2 through γ-aminopropyltriethoxysilane and nano-TiO 2 reaction, the nano-TiO 2 Amino groups are introduced into the surface.

[0039] Specifically, the carboxylation modified nano-TiO of the present invention 2 The preparation method of ultravi...

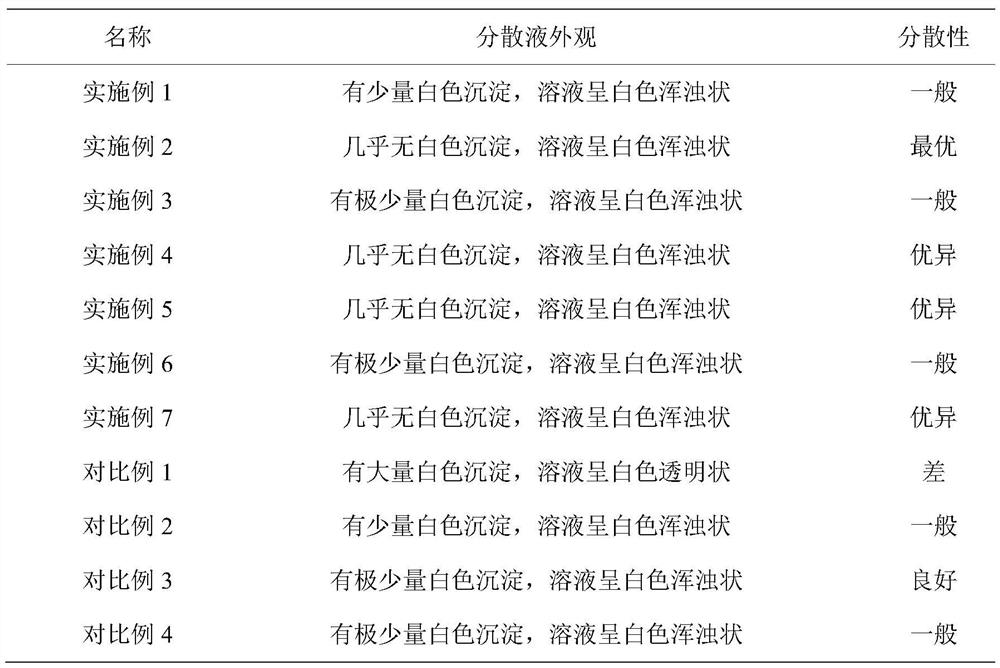

Embodiment 1

[0049] Step 1: TiO 2 -NH 2 preparation of

[0050] Weigh 1g nano TiO 2 Put it in an oven and dry it at 60°C for 4 hours to obtain dried nano-TiO 2 ; 0.5g gamma-aminopropyltriethoxysilane is added in the beaker that 150g absolute ethanol and ultrapure water mixed solution (the mass ratio of absolute ethanol and ultrapure water is 9:1) are housed, magnetic stirring, pre- Hydrolyzed for 50min to obtain γ-aminopropyltriethoxysilane prehydrolyzate; the dried nano TiO 2 Add 80g of absolute ethanol and ultrapure water mixed solution (mass ratio of absolute ethanol and ultrapure water is 4:1) into a beaker and ultrasonically disperse for 1h to obtain nano-TiO 2 dispersion, the nano-TiO 2 Pour the dispersion into a three-necked flask, heat and stir in a water bath, set the water bath temperature of the reaction system to 40°C, and the stirring speed to 300r / min, and add ammonia water to adjust the pH of the reaction system to neutral, and stir for 40 minutes to obtain a neutral N...

Embodiment 2

[0054] Step 1: TiO 2 -NH 2 preparation of

[0055] Weigh 1g nano TiO 2 Put it in an oven and dry it at 60°C for 4 hours to obtain dried nano-TiO 2 ; 0.5g gamma-aminopropyltriethoxysilane is added in the beaker that 150g absolute ethanol and ultrapure water mixed solution (the mass ratio of absolute ethanol and ultrapure water is 9:1) are housed, magnetic stirring, pre- Hydrolyzed for 50min to obtain γ-aminopropyltriethoxysilane prehydrolyzate; the dried nano TiO 2 Add 80g of absolute ethanol and ultrapure water mixed solution (mass ratio of absolute ethanol and ultrapure water is 4:1) into a beaker and ultrasonically disperse for 1h to obtain nano-TiO 2 dispersion, the nano-TiO 2 Pour the dispersion into a three-necked flask, heat and stir in a water bath, set the temperature of the water bath in the reaction system to 40°C, and the stirring speed to 300r / min, add sodium hydroxide to adjust the pH of the reaction system to neutral, and stir for 40 minutes to obtain Neutr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com