Combustion process of glass kiln with non-catalytic converter

A glass kiln and reforming furnace technology, applied in glass furnace equipment, chemical industry, glass production, etc., can solve problems such as pollution, heat loss, acid rain environment, etc., to reduce environmental pollution, reduce emissions, and reduce black smoke exhaust degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

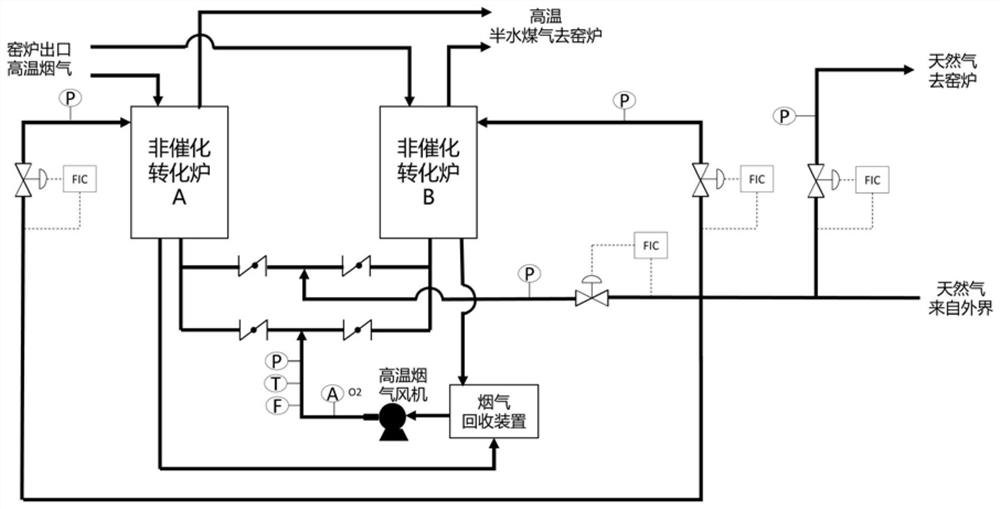

[0042] The present invention will be further explained below in conjunction with the embodiments and the accompanying drawings. The following examples are only used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0043] The mechanism of conventional air combustion:

[0044] C m h n +O 2 +N 2 →CO 2 +H 2 O+NO x ;

[0045] Carbon-based oxygen-enriched (H) of the present invention 2 O+CO 2 +O 2 ) combustion, natural gas and circulating flue gas rich in water vapor and carbon dioxide, the mechanism of conversion and reforming reaction:

[0046] combustion reaction

[0047] h 2 +1 / 2O 2 →H 2 O+242KJ / mol

[0048] CH 4 +2O 2 →CO 2 +2H 2 O+802KJ / mol

[0049] CO+O 2 →1 / 2CO 2 +393KJ / mol

[0050] Transformation reaction

[0051] CH 4 +1 / 2O 2 →CO+2H 2 +35.5KJ / mol

[0052] CH 4 +H 2 O→CO+3H 2 -206KJ / mol

[0053] CH 4 +CO 2 →2CO+2H 2 -247KJ / mol

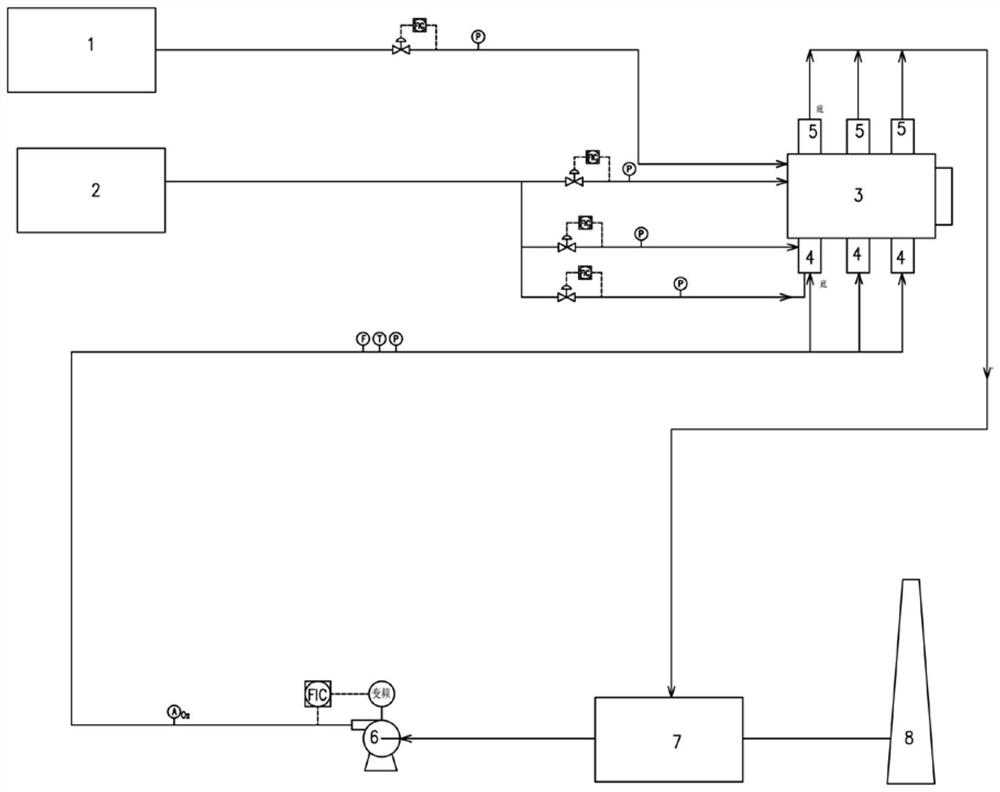

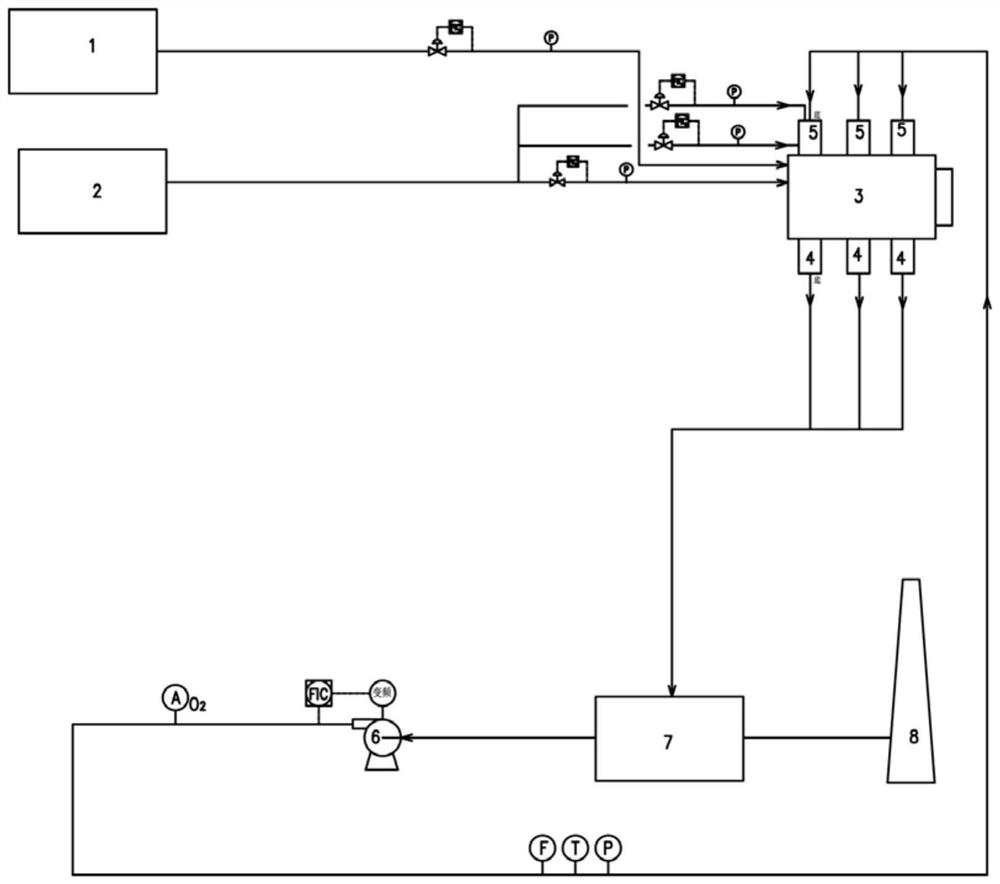

[0054] A glass kiln combustion process with a non-cata...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap