Manufacturing process and manufacturing formula of high-strength fireproof and moistureproof tray

A high-strength, pallet-based technology, applied in transportation and packaging, rigid containers, packaging, etc., can solve the problems of poor fire resistance and moisture resistance of pallets, and achieve the effects of improving heat resistance, reducing the growth of microorganisms and bacteria, and reducing mildew

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: This embodiment also includes 5-2 parts of high-temperature-resistant filler; the high-temperature-resistant additive is any one or more of glass fiber, aluminum oxide, and heavy calcium carbonate. Glass fiber has good heat resistance and tensile strength, thereby improving the heat resistance and toughness of the tray; alumina is a high-hardness compound with a high melting point, thereby improving the heat resistance and wear resistance of the tray; heavy carbonic acid High calcium strength, good heat insulation performance.

Embodiment 2

[0034] Embodiment 2: This embodiment also includes 5-2 parts of moisture-proof and mildew-proof fillers; the moisture-proof and mildew-proof fillers are one or more of dry powder anti-mold agents, activated carbon, and asbestos powder. Dry powder antifungal agent has the effect of killing or inhibiting mold, thereby reducing mildew on the surface of the tray; activated carbon has strong adsorption and good water resistance, thereby improving the water resistance of the tray; asbestos powder is a powdered non-metallic material containing asbestos fibers. Has good water resistance.

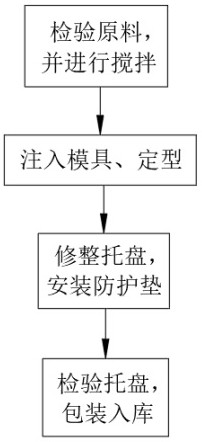

[0035] A manufacturing process of a high-strength fire-proof and moisture-proof pallet, comprising the following steps:

[0036] Step 1: Inspect the raw materials, fill them into the mixer according to the ratio, and fully stir and mix them;

[0037] Step 2: Inject the fully stirred and mixed raw materials into the mold for shaping;

[0038] Step 3: Trim the shaped pallet, remove burrs and burrs, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com