Low-viscosity reversible cross-linked polycaprolactone as well as preparation method and application thereof

A technology of polycaprolactone and cross-linked polymer, which is applied in the field of low-viscosity reversible cross-linked polycaprolactone and its preparation, can solve the problem of weakening of polymer mechanical properties, non-reprocessing of materials, inability of re-dissolution and melting of materials, etc. problems, achieve the effects of reducing melt viscosity, improving processing performance, and excellent recyclability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

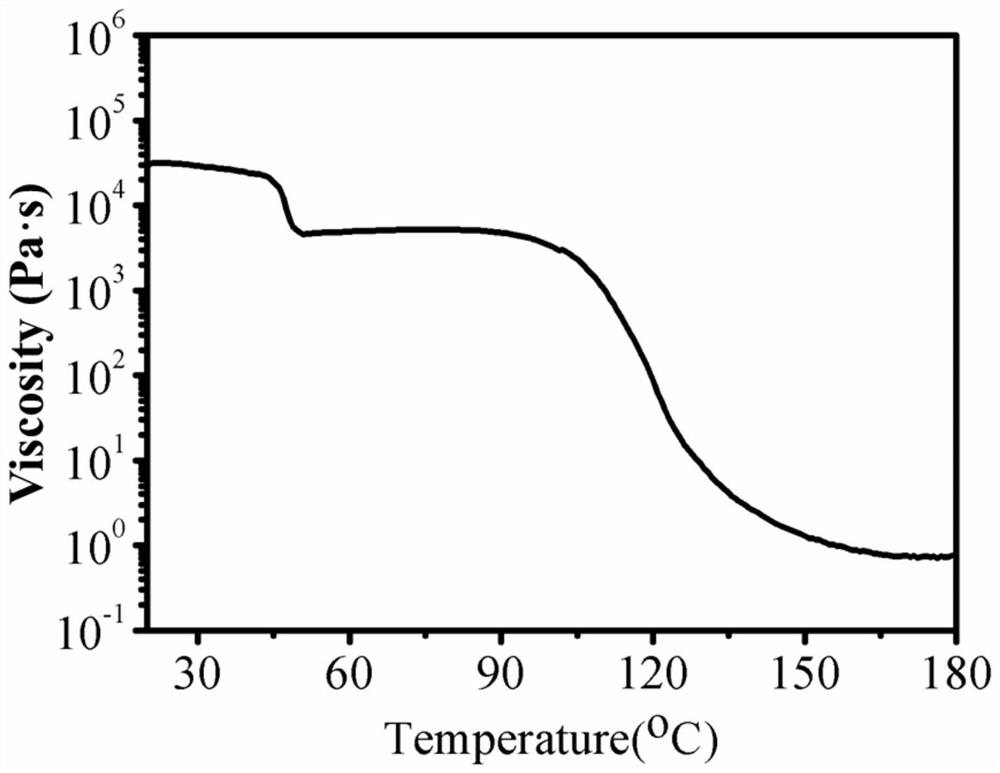

Examples

Embodiment 1

[0041] This embodiment provides a low-viscosity reversible cross-linked polycaprolactone, the preparation method of which comprises the following steps:

[0042] S1. Polycaprolactone grafted furan group

[0043] S11. Add 1 mol caprolactone, 0.02 mol pentaerythritol and 0.2 g stannous octoate into a nitrogen-protected single-necked bottle, rapidly raise the temperature to 120°C and stir for 12 hours to obtain polycaprolactone;

[0044]To the polycaprolactone obtained in S12.S11, add 400mL N,N-dimethylformamide, stir under dry nitrogen and room temperature until completely dissolved; add 0.096mol succinic anhydride and 0.096mol triethylamine; add After completion, stir at 50°C for 12 hours; distill under reduced pressure for 30 minutes, add diethyl ether to precipitate the product, and centrifuge and dry to obtain carboxyl-functionalized polycaprolactone;

[0045] The number-average molecular weight Mn of the carboxyl-functionalized polycaprolactone measured by nuclear magnetic...

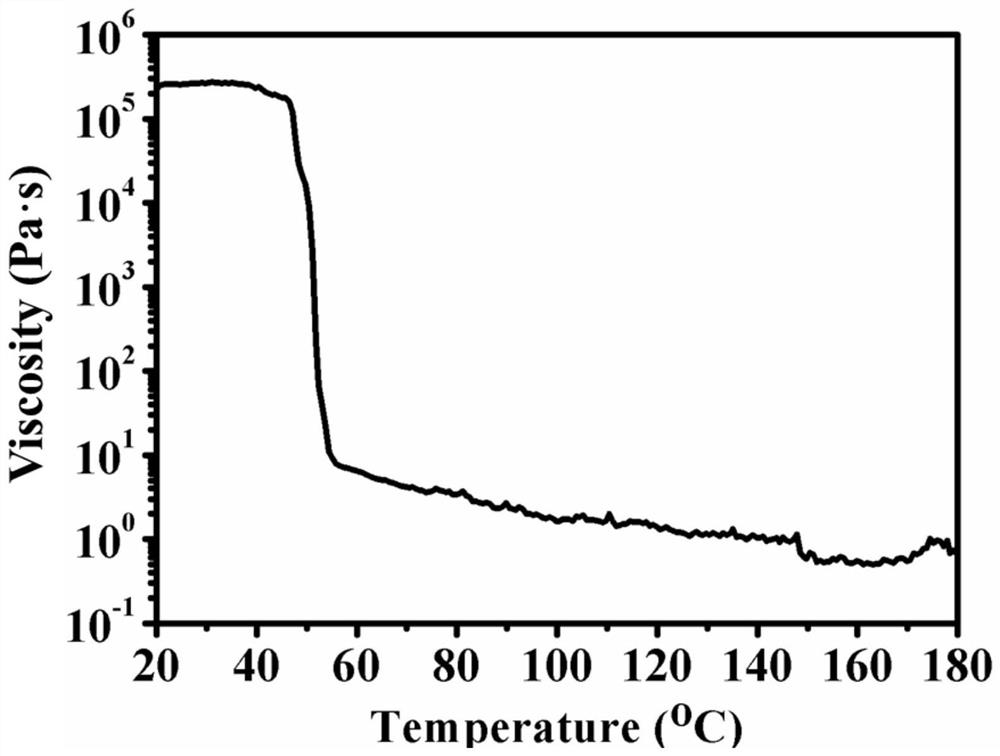

Embodiment 2

[0053] This example provides a low-viscosity reversibly cross-linked polycaprolactone. The difference between its preparation method and Example 1 is that the molar ratio of furan groups to maleimide functional groups in step S22 is 1:0.8.

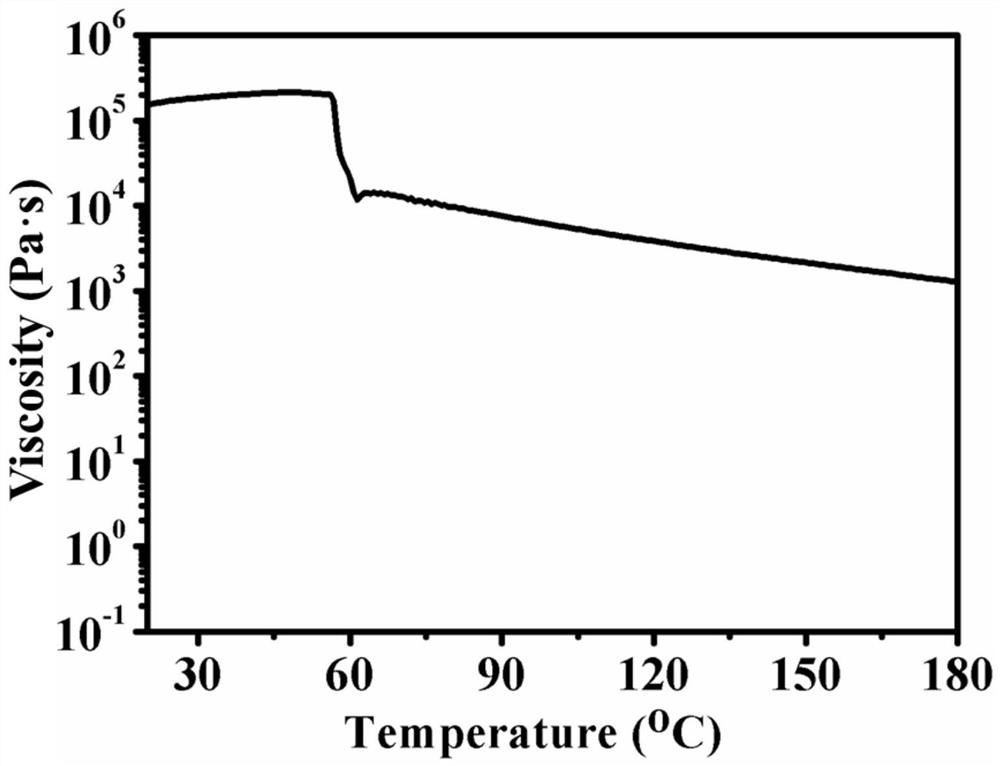

Embodiment 3

[0055] This example provides a low-viscosity reversibly cross-linked polycaprolactone. The difference between its preparation method and Example 1 is that the molar ratio of furan group to maleimide functional group in step S22 is 1:0.6.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com