Atomic force microscope-based material surface acid solution treatment mode

An acidic solution and surface smoothing technology, applied in the preparation of test samples, measuring devices, instruments, etc., can solve problems such as large charge, strong signal, difficult charge measurement and characterization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

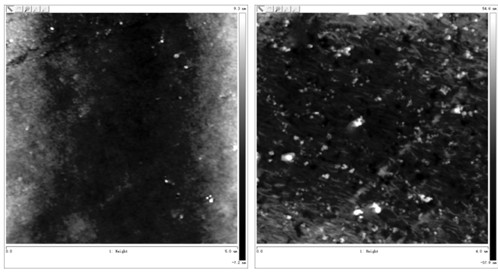

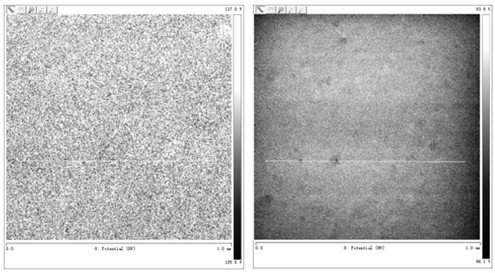

[0019] In the experiment, A200 hydrophilic nano-SiO2 produced by Degussa Company was selected as the introduction particle. Firstly, the nano-particles were put into an appropriate amount of alcohol to prepare a nano-particle dispersion, and then the dispersion was ultrasonically oscillated for 40 minutes to obtain a uniform nano-particle alcohol dispersion. liquid.

[0020] Put the polyethylene in a Hapro RM-A200 torque rheometer, set the temperature at 130°C, and drop the dispersion evenly when the polyethylene melts. After the dispersion liquid was dropped in, the sample was continuously stirred until the torque became stable, and then the sample was taken out to obtain the experimental material.

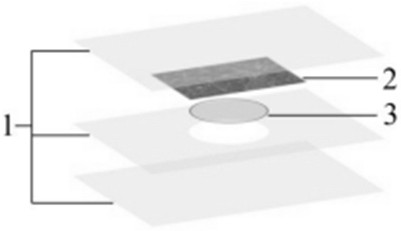

[0021] In order to make the surface of the sample smooth and fully expose the nanoparticles to the surface of the sample, the ultra-flat mica (2) surface is used to press the surface of the sample. First, the mica sheet is treated, and the surface of the mica sheet is glued down ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com