Simulation method for performance research of CO2 intelligent response type temperature-resistant and salt-resistant tertiary amine foam system

A foam system and simulation method technology, applied in chemical instruments and methods, drilling composition, design optimization/simulation, etc., can solve the response mechanism, the mechanism of temperature resistance and salt resistance has no clear explanation, and ordinary foam cannot realize intelligence Response, poor temperature resistance and salt resistance, etc., to achieve fast calculation, good foam stability, good foam stability and response performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

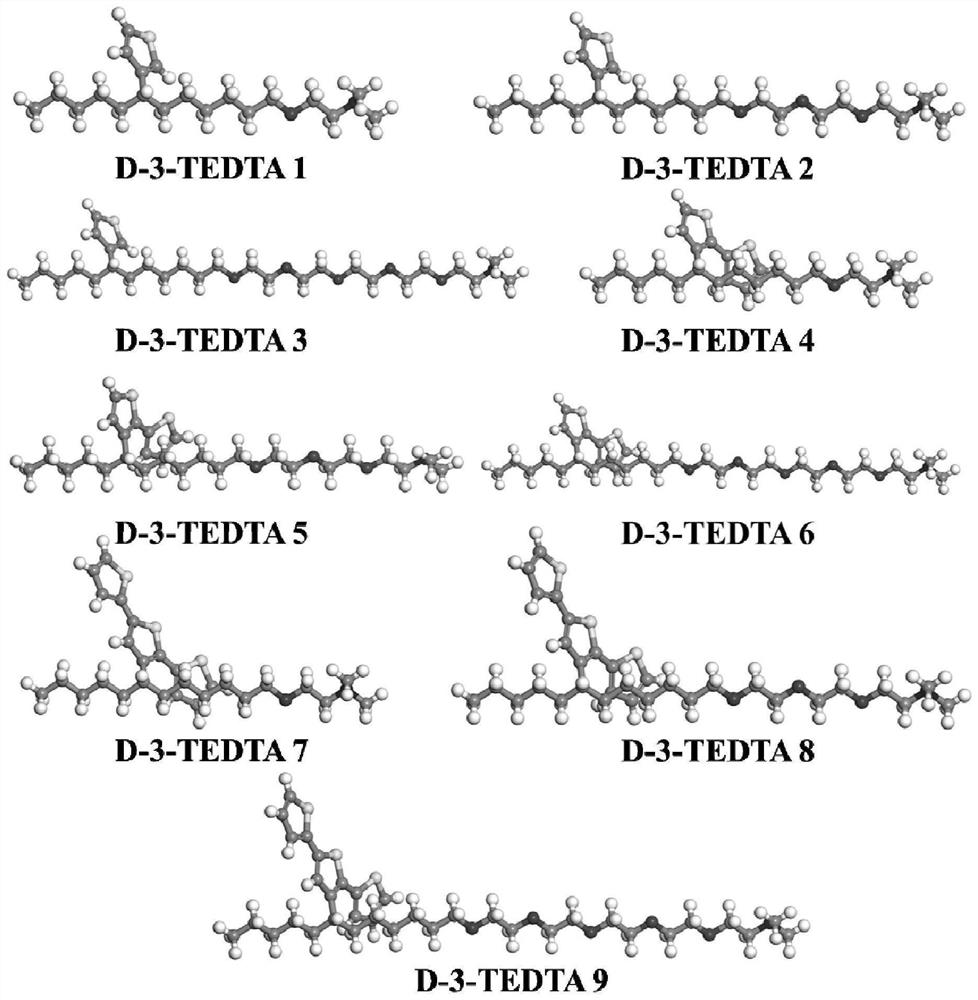

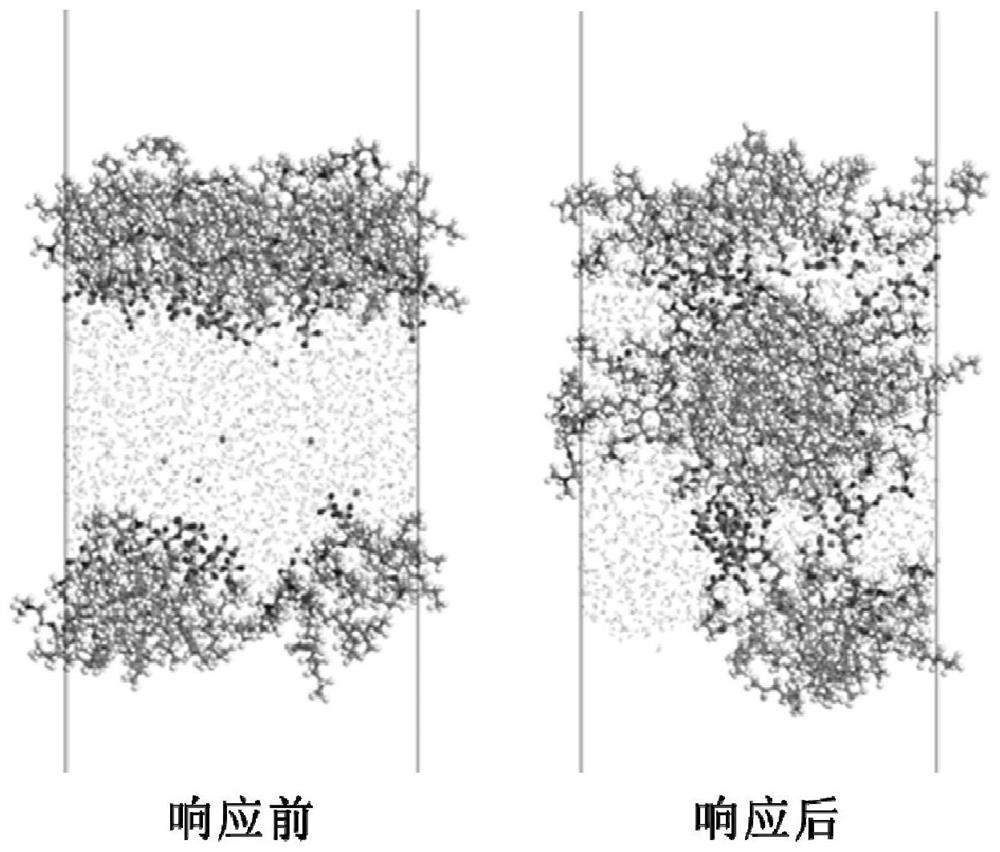

[0056] Such as image 3 As shown, under the conditions of temperature 298K and salinity 0mg / L, the design of SDS / D-3-TEDTA 2 foam system:

[0057] 1) Build the initial model

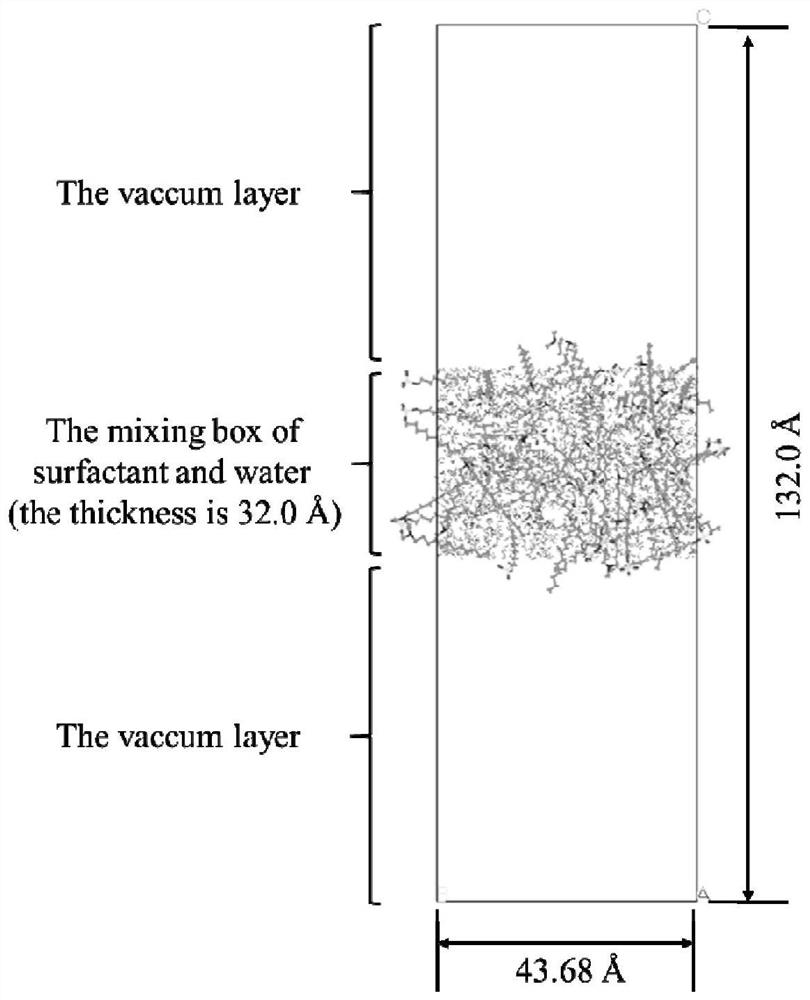

[0058] Use the Sketch tool in the Materials Studio software to construct the tertiary amine surfactant molecule N-dodecyl-N,N-dimethyl tertiary amine (C 12 A), traditional anionic surfactant molecules sodium dodecyl sulfate (SDS) and water molecules, by adding 1 temperature-resistant group thiophene group, 3 salt-resistant group ethoxy groups to tertiary amine surfactants Molecule N-dodecyl-N,N-dimethyl tertiary amine (C 12 A) Modified design to obtain D-3-TEDTA 2; use Amorphous Cell tool and build layer tool to compound 36 SDS and 36 D-3-TEDTA2 1:1 and mix with 2042 water molecules to construct SDS / D-3-The initial interface model of the TEDTA 2 foam system. Box size is 4.368×4.368×3.2nm 3 , add a 5nm vacuum layer on the upper and lower sides of the box.

[0059] 2) Optimizing the initial interfac...

Embodiment 2

[0066] Such as Figure 4 As shown, under the conditions of temperature 363K and salinity 0mg / L, the design of SDS / D-3-TEDTA2 foam system:

[0067] 1) Build the initial model

[0068] Use the Sketch tool in the Materials Studio software to construct the tertiary amine surfactant molecule N-dodecyl-N,N-dimethyl tertiary amine (C 12 A), traditional anionic surfactant molecules sodium dodecyl sulfate (SDS) and water molecules, by adding 1 temperature-resistant group thiophene group, 3 salt-resistant group ethoxy groups to tertiary amine surfactants Molecule N-dodecyl-N,N-dimethyl tertiary amine (C 12 A) Modified design to obtain D-3-TEDTA 2; use Amorphous Cell tool and build layer tool to compound 36 SDS and 36 D-3-TEDTA 2 1:1 and mix with 2042 water molecules to construct The initial interface model of the SDS / D-3-TEDTA 2 foam system. Box size is 4.368×4.368×3.2nm 3 , add a 5nm vacuum layer on the upper and lower sides of the box.

[0069] 2) Optimizing the initial interfac...

Embodiment 3

[0076] Such as Figure 5 As shown, under the conditions of temperature 298K and salinity 200000mg / L, the design of SDS / D-3-TEDTA 2 foam system:

[0077] 1) Build the initial model

[0078] Use the Sketch tool in the Materials Studio software to construct the tertiary amine surfactant molecule N-dodecyl-N,N-dimethyl tertiary amine (C 12 A), traditional anionic surfactant molecules sodium dodecyl sulfate (SDS), water molecules and inorganic salt ions, by adding 1 temperature-resistant group thiophene group, 3 salt-resistant group ethoxy groups for tertiary Amine surfactant molecule N-dodecyl-N,N-dimethyl tertiary amine (C 12 A) Modified design to obtain D-3-TEDTA 2; use AmorphousCell tool and build layer tool to carry out 1:1 compounding of 36 SDS and 36 D-3-TEDTA 2 and mix with 2042 water molecules, 200000mg / L Salinity of inorganic salt ions (100 Na + , 6 Mg 2+ , 6 Ca 2+ , 124 Cl - ) to build the initial interface model of the SDS / D-3-TEDTA 2 foam system. Box size is 4....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com