A kind of preparation method and application of few-layer graphene powder

A technology of few-layer graphene and powder, which is applied in the field of preparation of few-layer graphene powder, can solve problems such as the influence of graphene on electrical and thermal conductivity, the large influence of graphene quality, and the influence of graphene quality, so as to improve the quality of graphite Stripping efficiency, improvement of charge and discharge capability, effect of suppressing crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preparation method of few-layer graphene powder of the present invention, comprises the following steps:

[0032] S1: Stir 85 parts of deionized water and 5 parts of 2000-mesh ultrafine barium sulfate at a speed of 6000rpm for pre-dispersion for 60 minutes to obtain an intercalation agent pre-dispersion;

[0033] S2: Shear the pre-dispersed liquid of S1 at ultra-high speed for 60 minutes at a shear line speed of 50 m / s to obtain a fully dispersed and uniform intercalant dispersion;

[0034] S3: Add 9 parts of 400-fold expanded graphite and 3 parts of ethylene glycol to the agent dispersion prepared in S2, and stir and pre-disperse at 4000 rpm for 50 minutes to obtain a pre-dispersion of expanded graphite and intercalation agent;

[0035] S4: The pre-dispersed liquid obtained in S3 is peeled by ultra-high-speed shearing, the shearing line speed is 50m / s, and the high-speed shearing is 100min, to obtain the graphene coarse dispersion liquid that is initially peeled off;...

Embodiment 2

[0042] A preparation method of few-layer graphene powder of the present invention, comprises the following steps:

[0043] S1: Stir 88 parts of deionized water and 2 parts of carbon nanotubes at a speed of 6000 rpm for pre-dispersion for 60 minutes to obtain an intercalation agent pre-dispersion;

[0044] S2: The pre-dispersed liquid of S1 was subjected to ultra-high-speed shearing for 60 minutes at a shear line speed of 40m / s to obtain a fully dispersed and uniform intercalant dispersion;

[0045] S3: Add 9 parts of 400 times expanded graphite and 3 parts of ethylene glycol to the nano-intercalation solution prepared in S2, and stir at a high speed of 5000rpm for 30 minutes to obtain a pre-dispersion of expanded graphite and intercalation agent ;

[0046] S4: The pre-dispersion of S3 is peeled by ultra-high-speed shearing, the shearing line speed is 60m / s, and the high-speed shearing is 120min, to obtain the graphene coarse dispersion liquid that is initially peeled off;

[0...

Embodiment 3

[0053] A preparation method of few-layer graphene powder of the present invention, comprises the following steps:

[0054] S1: Stir 85 parts of deionized water and 5 parts of spherical alumina at a speed of 6000 rpm for pre-dispersion for 50 minutes to obtain an intercalation agent pre-dispersion;

[0055] S2: The pre-dispersed liquid of S1 was subjected to ultra-high-speed shearing for 60 minutes at a shear line speed of 40m / s to obtain a fully dispersed and uniform intercalant dispersion;

[0056] S3: Add 9 parts of 400 times expanded graphite and 3 parts of ethylene glycol to the intercalation dispersion prepared in S2, and stir and pre-disperse at 4000 rpm for 50 minutes to obtain a pre-dispersion of expanded graphite and intercalation agent;

[0057] S4: The pre-dispersion of S3 is sheared and peeled by ultra-high-speed shearing, the shearing line speed is 60m / s, and the high-speed shearing is 100min, to obtain a rough dispersion of graphene that is initially peeled off; ...

PUM

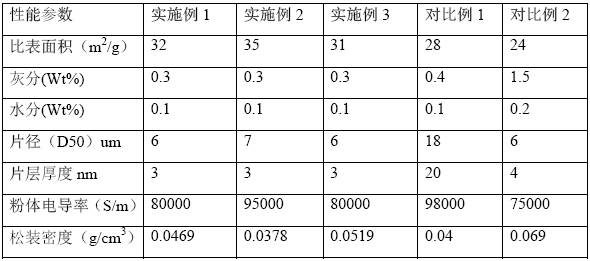

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com