A kind of dioxaborane group modified barium titanate with reversible crosslinking structure and preparation method thereof

A technology of dioxaborane and cross-linked structure is applied in the field of dioxaborane group modification of barium titanate and its preparation, which can solve the problem of the disappearance of functions such as self-healing of Vitrimer materials and the combination of barium pertitanate and polymers. The problem is that the ability is not strong enough, the cross-linked structure of the polymer is destroyed, etc., to achieve the effect of a clear reaction principle, a novel synthesis route, and a simple implementation of the synthesis process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Barium titanate (≥98%), silane coupling agent (KH550, ≥99.5%; KH560, ≥98%), ethanol (≥99.7), 4-carboxyphenylboronic acid (≥98%), Propylene glycol (≥99%), anhydrous magnesium sulfate (≥98%), tetrahydrofuran (≥99.9%), thionyl chloride (1mol / L), N,N-dimethylformamide (≥98%) and benzene Boric acid (≥98%) was purchased from Saen Chemical Technology (Shanghai) Co., Ltd.

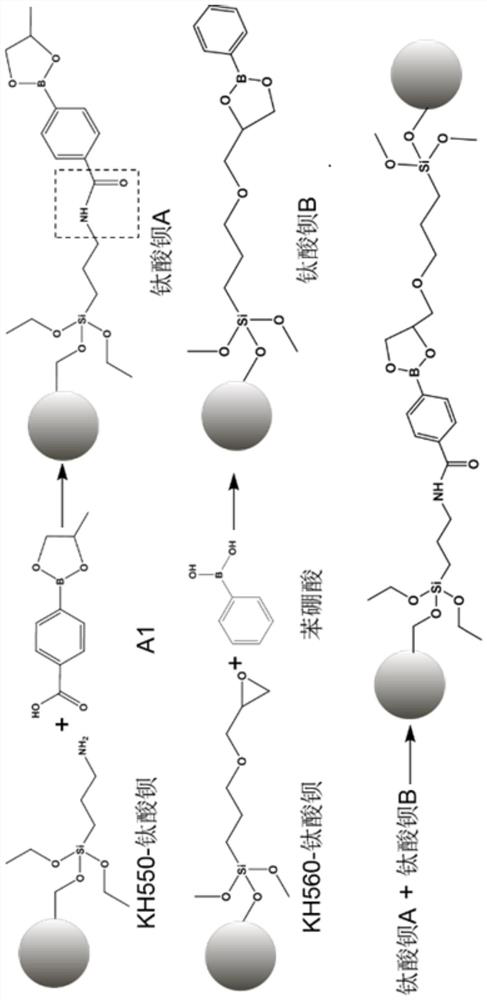

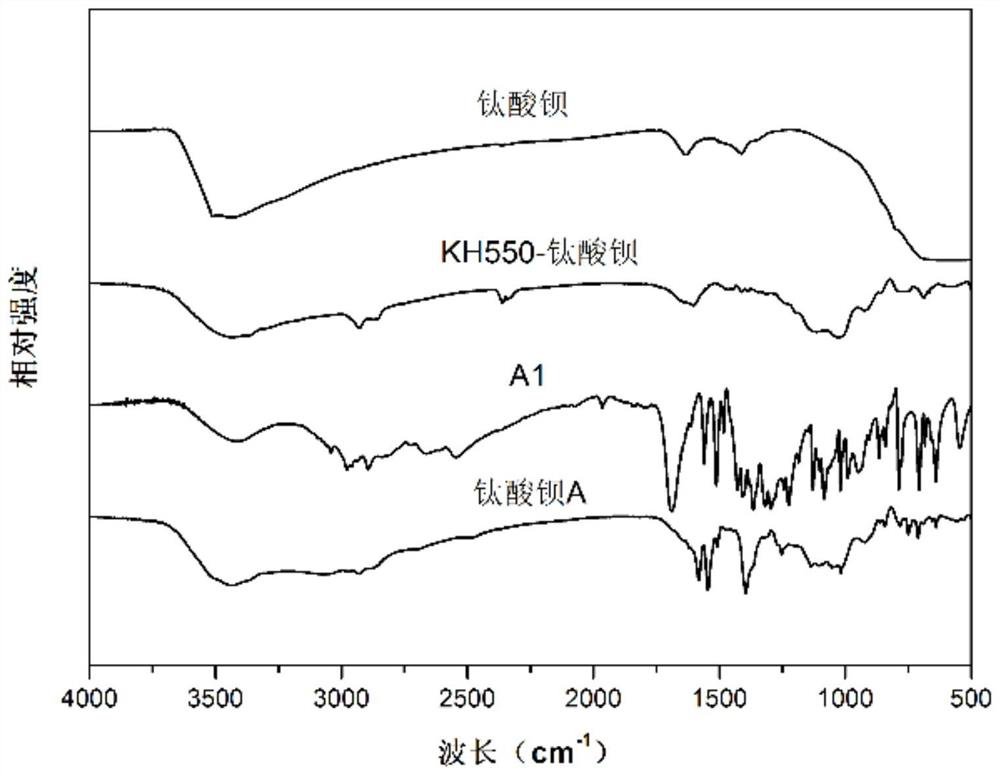

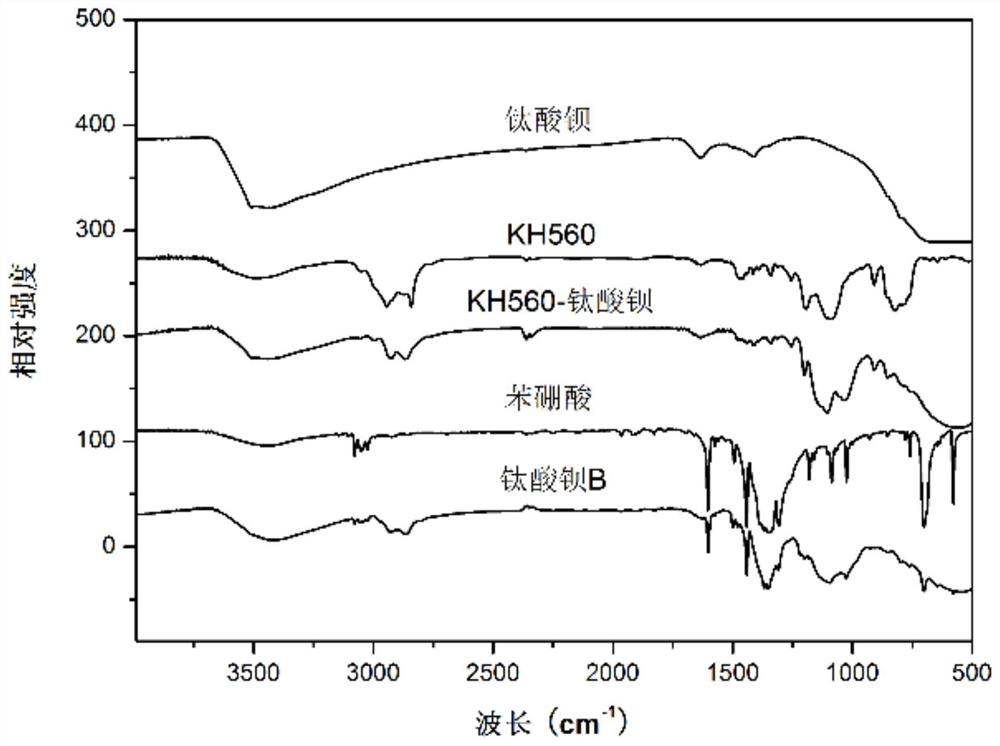

[0036] like figure 1 As shown in this example, the dioxaborane group-modified barium titanate with a reversible cross-linking structure was prepared by a three-step method. Firstly, according to the coupling reaction principle of silane coupling agent to inorganic particles containing hydroxyl groups on the surface, two kinds of silane coupling agents, KH550 and KH560, were used to modify barium titanate particles, and two kinds of coupling agents modified barium titanate (KH550- barium titanate and KH560 - barium titanate). Secondly, the dioxaborane group is grafted onto the silane coupling agent molecul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com