High-elastic flame-retardant conductive fiber and preparation method thereof

A conductive fiber, high-elastic technology, applied in the direction of flame retardant fiber, fiber type, fiber treatment, etc., can solve the problem of fiber conduction and resistance uniformity that does not fundamentally solve, can not guarantee the stability of conductive resistance, conductive fiber problems such as poor resistance uniformity, to achieve the effects of stable and controllable product quality, improved resistance uniformity and stability, and good application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

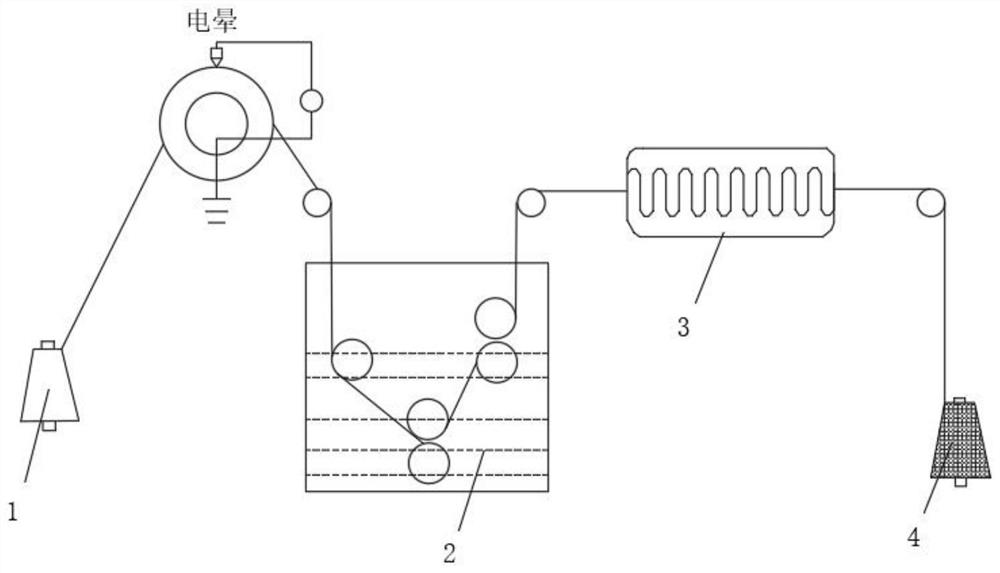

[0034] This embodiment provides a specific structure of a high-elastic flame-retardant conductive fiber, such as figure 1 Shown, comprise each component of following mass parts:

[0035] 5-20 parts of 5% water-based graphene dispersion; 40-60 parts of 5% water-based carbon nanotube dispersion; 10-30 parts of water-based flexible resin adhesive; 1-5 parts of flame retardant; 0.01-1 parts of defoamer 1-5 parts of dispersant; 0.1-1.5 parts of wetting agent; 0.1-5 parts of thickener.

[0036] Further, the composite flame retardant slurry includes the following components in parts by mass:

[0037] 17 parts of 5% water-based graphene dispersion; 50 parts of 5% water-based carbon nanotube dispersion; 25 parts of water-based flexible resin adhesive; 2.5 parts of flame retardant; 0.5 parts of defoaming agent; 2 parts of dispersant; wetting agent 0.5 parts; 3 parts of thickener.

[0038] The 5% aqueous graphene dispersion is a single-layer or 3-5-layer graphene solution.

[0039] T...

Embodiment 2

[0045] This embodiment provides a specific structure of a method for preparing a high-elastic flame-retardant conductive fiber, such as figure 1 shown, including the following steps:

[0046] Preparation of slurry: Add the raw materials of each component into the stirring grinder, pre-disperse at a stirring speed of 800rpm-1500rpm, add zirconia beads for grinding, and prepare water-based CNTs-graphene composite flame-retardant slurry with an average particle size of 500nm The raw material is for use, wherein the volume ratio of zirconia beads is 65-80%, the diameter is 1.0mm or 2.0mm, the grinding speed is 750rpm-1000rpm, and the grinding time is 25min-45min;

[0047]Preparation of conductive fiber: Corona treatment is performed on the substrate fiber to generate free radicals or ionic groups on the surface, set the parameters of the thread dyeing machine, adjust the tension, and stretch the fiber to a length of 50%-150%. Carry out a dyed thread through sizing, stretch the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com