Anti-hardening acid-corrosion-resistant fluffy biological deodorization composite filler

A technology of biological deodorization and composite filler, which is applied in the separation of dispersed particles, air quality improvement, chemical instruments and methods, etc., can solve the problem of high energy consumption of filler layer filtration, difficulty in deodorization effect reaching high standard requirements, and limited specific surface area. and other issues to achieve the effect of low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

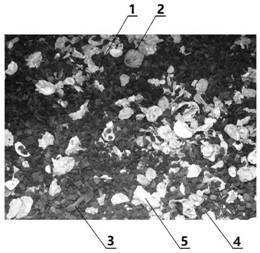

Image

Examples

Embodiment 1

[0105] Please refer to the attached figure 1 , and combined with the biological deodorization project of a sewage treatment plant in Hainan Province, the composite filler of the present invention is used as an example, and the present invention is further described in detail.

[0106] The sewage treatment scale of this embodiment is 8000m 3 / d, divided into 2 blocks of 4000m each 3 / d rectangular biochemical reaction pool. Set up two independent biological deodorization filter system devices, one of which is used for odor treatment of biochemical pools, and the other is used for odor treatment of water inlet pump room and sludge dehydration; for the convenience of operation and management, two biological The specifications of the deodorizing filter are the same, and the deodorizing air volume is 3800m 3 / h, the tail gas of the two biological deodorization filters is discharged at a height of 15m through the jointly built wind tower. GB18918) stipulated standards. The deod...

Embodiment 2

[0117] Please refer to the attached figure 1 , and combined with the biological deodorization project of a centralized sewage treatment plant in an industrial park in Fuling, Chongqing, the composite filler of the present invention is used as an example to further describe the present invention in detail. Therefore, this embodiment provides another practical and feasible technical solution that has been successfully used.

[0118] The sewage treatment scale of this embodiment is 5000m 3 / d, set up a biological deodorization filter system device, which is used to treat the odor in the water inlet pump room, fine grid grit chamber, biochemical reaction tank and sludge dehydration room, and the deodorization air volume is 4800m 3 / h, the odor discharge standard at the factory boundary is required to meet the standards stipulated in the national standard "Discharge Standard of Odor Pollutants" (GB14554) and "Discharge Standard of Pollutants for Urban Sewage Treatment Plants" (GB1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com