A kind of organic small molecule gel and its preparation method and application

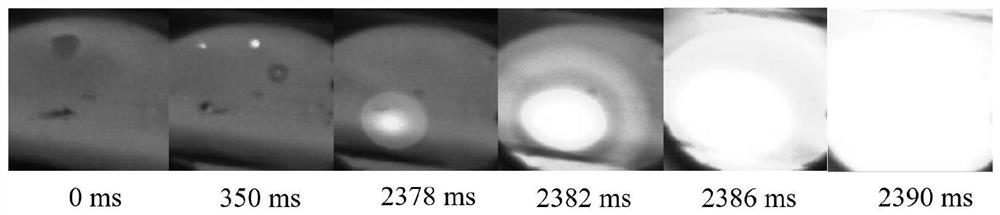

A small-molecule, organic technology, applied in the field of organic small-molecule gelling agents and their preparation, can solve problems such as reducing the burning rate, and achieve the effects of shortening the ignition delay, improving the burning performance, and increasing the burning rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The present invention provides the preparation method of organic small molecule gelling agent described in above-mentioned technical scheme, comprises the following steps:

[0038] Mix D-mannitol, compounds containing high tension structures, catalysts and organic solvents for condensation reaction to obtain organic small molecule gelling agents;

[0039] The compound containing high tension structure has the structure shown in formula II or formula III:

[0040] In formula II and formula III, R includes R 1 Including -H, -CH 3 、-CH 2 CH 3 or Cl.

[0041] In the present invention, unless otherwise specified, the required preparation materials are commercially available products well known to those skilled in the art.

[0042] The invention mixes D-mannitol, a compound containing a high tension structure, a catalyst and an organic solvent to carry out condensation reaction. In the present invention, the compound containing high tension structure preferably incl...

Embodiment 1

[0054] Dissolve 9.11g (0.05mol) of D-mannitol and 6.82g (0.05mol) of zinc chloride in 100mL DMF, add 8.41g (0.15mol) of cycloacetone, and stir for 12 hours at 25°C; Add 100mL saturated sodium chloride solution and 100mL dichloromethane into the obtained system and stir for 15min, filter the obtained material and wash with 100mL dichloromethane, extract the aqueous phase with dichloromethane, combine the organic phases and wash with saturated NaCl solution, wash the obtained Anhydrous Na 2 SO 4 dry. Filter, carry out rotary evaporation, obtain organic small molecule gelling agent 5.1g, structural formula is:

[0055]

Embodiment 2

[0057] Dissolve 9.11g (0.05mol) of D-mannitol and 6.82g (0.05mol) of zinc chloride in 100mL DMF, add 10.51g (0.15mol) of cyclopropanaldehyde, and stir at 25°C for 12h; after the reaction is completed, Add 100mL saturated sodium chloride solution and 100mL dichloromethane into the obtained system and stir for 15min, filter the obtained material and wash with 100mL dichloromethane, extract the aqueous phase with dichloromethane from the obtained washed material, combine the organic phases and wash with saturated NaCl solution Washed, the resulting material was washed with anhydrous Na 2 SO 4 After drying, after filtering, rotary evaporation is carried out to obtain 6.0 g of small molecule gelling agent, and the structural formula is:

[0058]

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com