Nickel selenide-trinickel diselenide nanorod composite material, and preparation method and application thereof

A technology of composite materials and nickel selenide, which is applied in the direction of nanotechnology, nanotechnology, hybrid/electric double layer capacitor manufacturing, etc., to achieve the effect of cheap and easy-to-obtain raw materials, simple process flow, and good electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Dissolve 0.8mmoL of Se powder into 20mL of anhydrous ethylenediamine to form a uniform solution A, then add 10mL of anhydrous ethanol mixed homogeneous solution to solution A, and stir thoroughly with magnetic stirring to form a uniform solution B. Finally, transfer the uniform solution B to a 100mL polytetrafluoroethylene reactor and add the treated foam nickel (3cm×2cm×1.5mm), and react in a blast drying oven at 180°C for 10h to prepare the composite material Ni 3 Se 2 / NiSe.

Embodiment 2

[0023] On the basis of Example 1, the reaction temperature was adjusted to be 160 degrees centigrade, and the time was 12 hours.

Embodiment 3

[0025] On the basis of Example 1, the reaction temperature was adjusted to be 190 degrees centigrade, and the time was 8 hours.

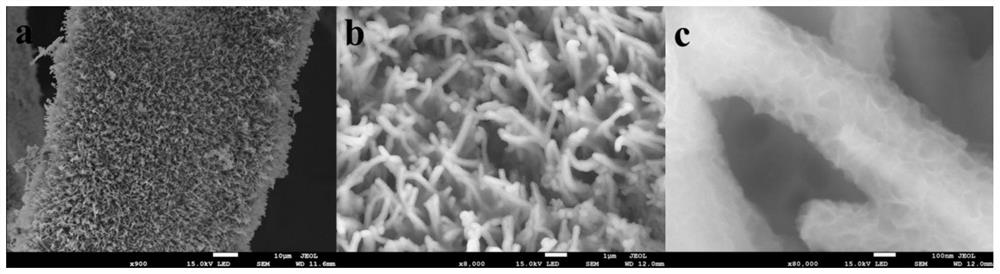

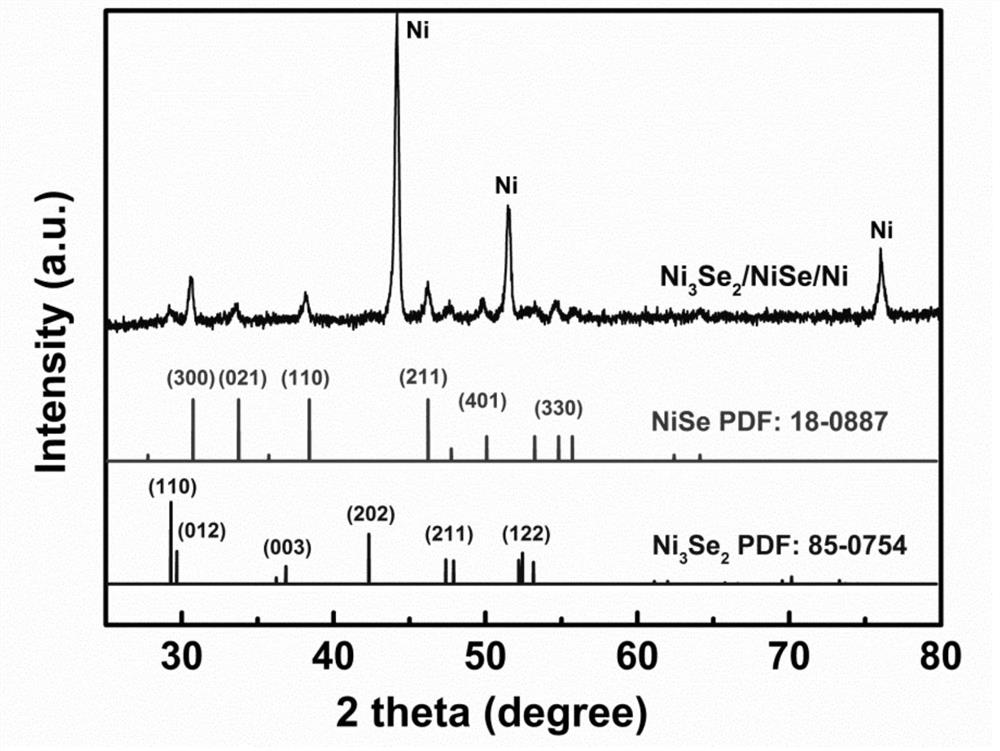

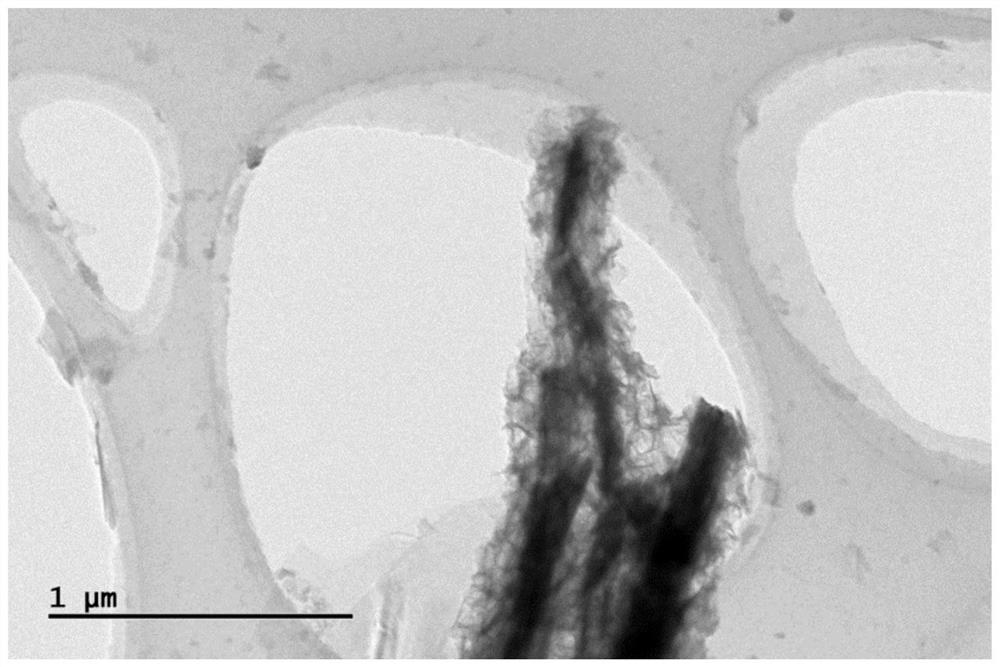

[0026] The following composite structure Ni 3 Se 2 / NiSe electrode material is example, to the Ni of the present invention preparation 3 Se 2 / NiSe nanorod composite structure electrode material (Example 1) for characterization. SEM picture as figure 1 As shown, it can be clearly seen that nanorods grow in situ on the surface of nickel foam, and the growth on the nickel foam is very uniform and has a firm structure. figure 2 is the X-ray powder diffraction (XRD) pattern of the electrode material. The data at 29.6°, 29.9°, 37.2°, 47.7° and 52.7° correspond to Ni 3 Se 2 (JCPDS No.85-0754) characteristic peak, the corresponding crystal planes of the peaks are (110), (012), (003), (211) and (122) crystal planes respectively; and at 31.0°, 34.0° , 38.7°, 48.0°, 50.4° and 55.1° correspond to the characteristic peaks of NiSe (JCPDS No.18-0887), an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com