Composite new material brake drum

A new material and brake drum technology, applied in the direction of brake drums, manufacturing tools, friction linings, etc., can solve the problems of easy cracks in the braking surface materials, reduce the tendency of thermal failure, improve braking efficiency, and improve The effect of binding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The present invention provides a method for preparing the graded wear-resistant gray iron material described above, comprising the steps of continuously cast iron water to obtain a gradient wear-resistant gray iron material. In the present invention, the continuous casting is preferably a centrifugal casting process; the present invention is not particularly limited for the conditions of the centrifugal casting process, and it is possible to prepare a gradient wear-resistant gray iron material. In the present invention, the continuous casting includes a first stage casting, a second stage casting, a third stage casting, and a fourth stage cast, the first stage cast iron chemical composition and the bonding layer The chemical composition is the same; the iron hydrophilic composition of the second stage cast is the same as the chemical composition of the proximal bonding layer; the iron hydrothermal chemical composition of the third stage cast is the same as the chemical comp...

Embodiment 1

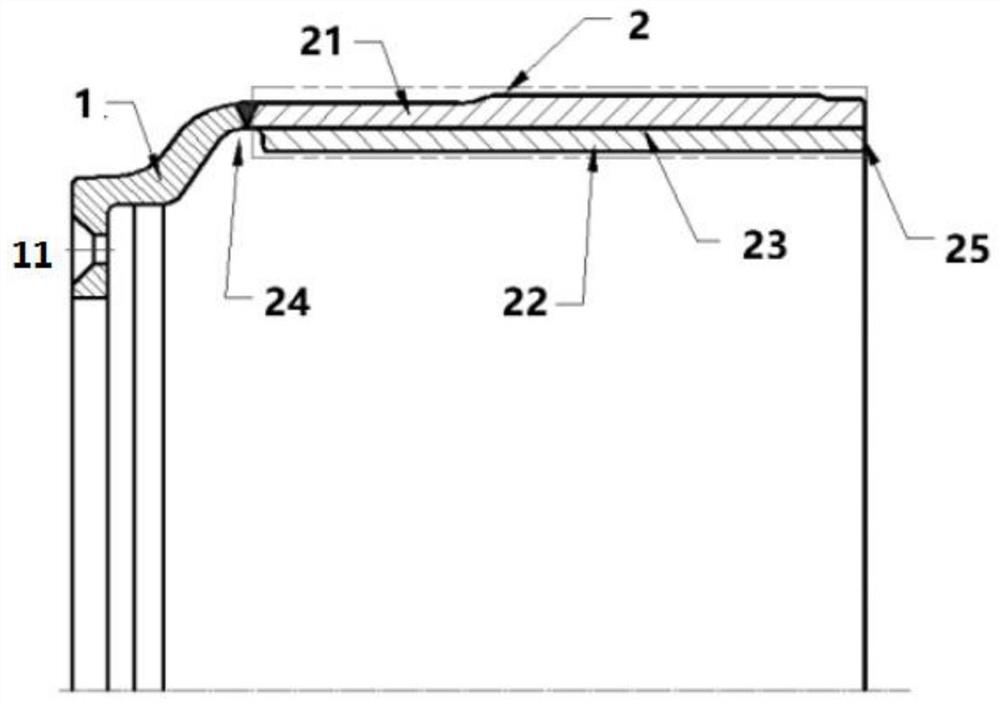

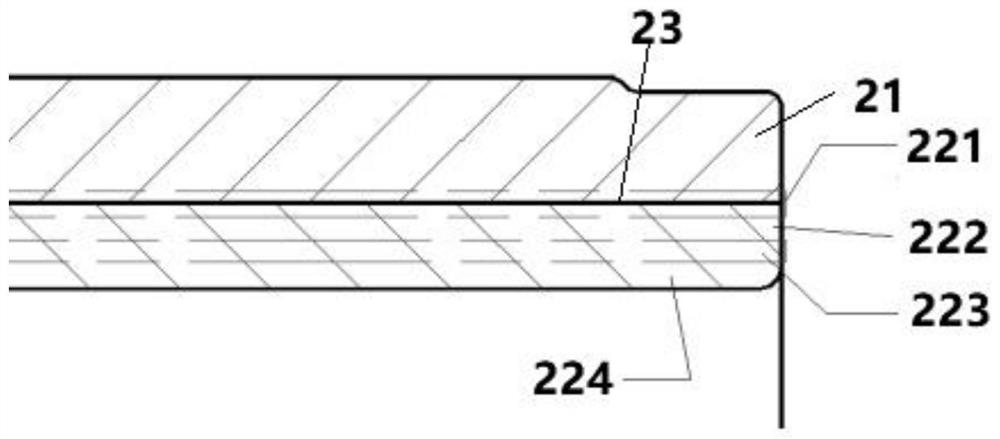

[0071] The centrifugal casting process is used, and the iron water is continuously cast, and the gradient wear-resistant gray iron material is obtained; the continuous casting includes the first stage casting, the second stage casting, the third stage castings and the fourth stage casting; the casting process is continuous during the casting process Pouring iron water is added to graphite, silicon, manganese, chromium and sulfur, enabling the first phase of casting, second stage casting, third stage casting, and chemical composition of iron water in the fourth stage casting, the bonding layer in Table 1, respectively. The chemical composition of the bonding layer, the central layer, and the brake surface layer is the same; the thickness of the outer high strength steel, the bonding layer, the near-bonding layer, the center layer, and the brake surface layer are 1 to 3 mm, 0.3 to 2 mm, 0.7 to 3 mm, respectively. And 1 ~ 5mm.

[0072] Table 1 Chemical composition of each layer of gr...

Embodiment 2

[0075] The high-strength steel plate is rotated to obtain flange;

[0076] With a centrifugal casting process, high-strength steel water is poured. When the temperature of the high-strength steel is reduced to the iron water solid phase line temperature (0 / -150 ° C), the iron water is continuously poured, resulting in a composite new material brake surface; the continuous casting includes The first stage casting, the second stage casting, the third stage castings and the fourth stage casting; the pouring process is added to the continuous cast iron water, such as the first stage cast, second The chemical composition of iron water during stage casting, third stage casting and fourth stage casting is the same as the bonding layer, the near-bonding layer, the central layer, and the brake surface layer in Table 1, and the outer high strength steel, bonding layer The thickness of the bonding layer, the central layer, and the brake surface layer is 6 to 20 mm, 1 to 3 mm, 0.3 to 2 mm, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com