Culture method of anaerobic ammonia oxidation granular sludge with blue iron ore core

An anaerobic ammonia oxidation and granular sludge technology, applied in chemical instruments and methods, water/sludge/sewage treatment, aerobic and anaerobic process treatment, etc., can solve the problem of poor settling performance, easy sludge loss, nitric acid Salt by-products affect the process compliance discharge and other problems, to achieve the effect of strengthening denitrification, increasing affinity, and improving total nitrogen removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] The present embodiment provides a method for cultivating anaerobic ammonium oxidation granular sludge with a blue iron core, and the specific steps are as follows:

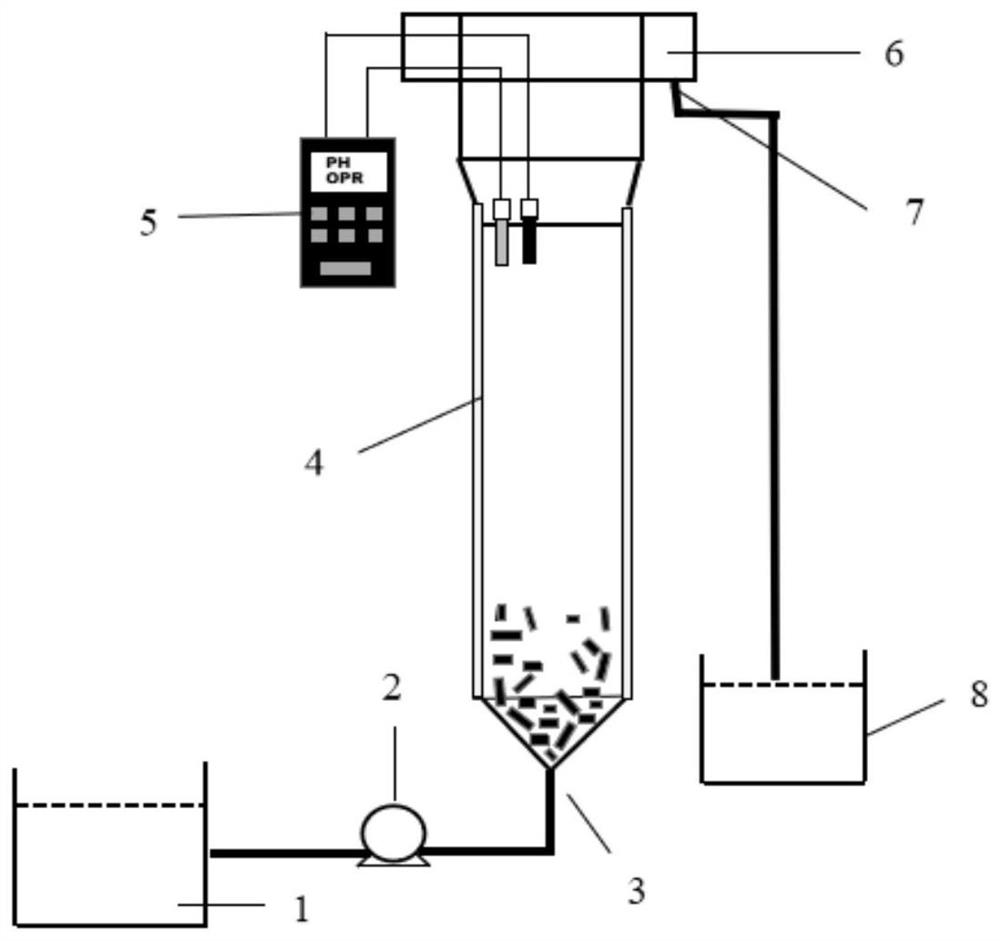

[0057] Take an upflow anaerobic sludge bed reactor with an effective volume of 2.5L, the structure is as follows figure 1 As shown, add 180g·L in the reactor main body 6 -1 Granular activated carbon was used as a biological carrier, inoculated with anaerobic ammonium oxidation granular sludge, and the suspended solids concentration of the mixed liquid of anaerobic ammonium oxidation granular sludge was 2g L -1 , using simulated wastewater as influent, the reactor operates under the conditions of anaerobic, dark, temperature 35±1°C, hydraulic retention time 5.4h, and the reactor main body 6 is heated by water bath heating 4 .

[0058] The composition of the simulated wastewater is: ammonia nitrogen 50-210mg L -1 , Nitrite nitrogen 50-210mg·L -1 , phosphate 8-44mg·L -1 , KHCO 3 125mg·L -1 ,EDTA 5mg·L ...

Embodiment 2

[0068] The present embodiment provides a method for cultivating anaerobic ammonium oxidation granular sludge with a blue iron core, and the specific steps are as follows:

[0069] Take an upflow anaerobic sludge bed reactor with an effective volume of 2.5L, and inoculate the anammox granular sludge in the reactor main body 6, and the suspended solid concentration of the mixed liquid of the anammox granular sludge is 2g L -1 , using simulated wastewater as influent, the reactor operates under the conditions of anaerobic, dark, temperature 35±1°C, hydraulic retention time 5.4h, and the reactor main body 6 is heated by water bath heating 4 .

[0070] The composition of the simulated wastewater is: ammonia nitrogen 50-230mg L -1 , Nitrite nitrogen 50-230mg·L -1 , phosphate 6-49mg·L -1 , KHCO 3 125mg·L -1 ,EDTA 5mg·L -1 and trace elements Ⅰ 2mL·L -1 , Trace element II 1mL·L -1 , the solvent is water, wherein the composition of trace elements is the same as in Example 1.

...

experiment example

[0087] The granular sludge obtained in the embodiment of the present invention and the comparative example is tested for performance, including sedimentation performance, mechanical strength, particle size, bacterial load density, etc. The specific test methods and test results are as follows:

[0088] 1. Settling performance: The settling performance index of sludge is characterized by sludge volume index (SVI). Firstly, the concentration of mixed liquid suspended solids (MLSS) is measured by the standard gravimetric method, that is, a certain volume of complete muddy water mixture is dried at 105°C to constant weight, and the weighing value is divided by the volume of the mixed liquid to obtain MLSS, and then settle for 30 minutes The sludge sedimentation ratio (SV) was measured by the method, that is, the volume of the activated sludge after settling in a 1000 ml measuring cylinder for 30 minutes was SV30. The SVI value is the ratio of SV30 to MLSS.

[0089] 2. Mechanical ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com