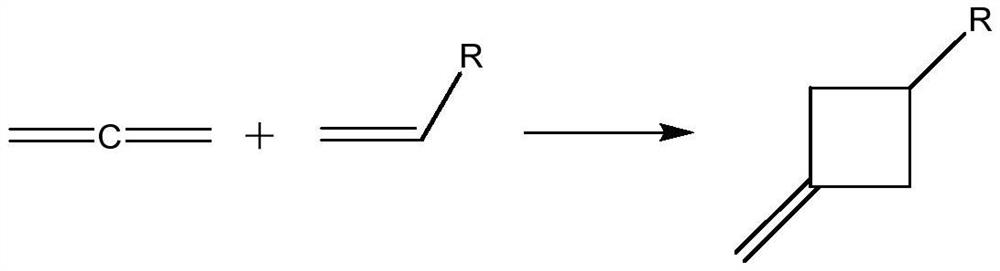

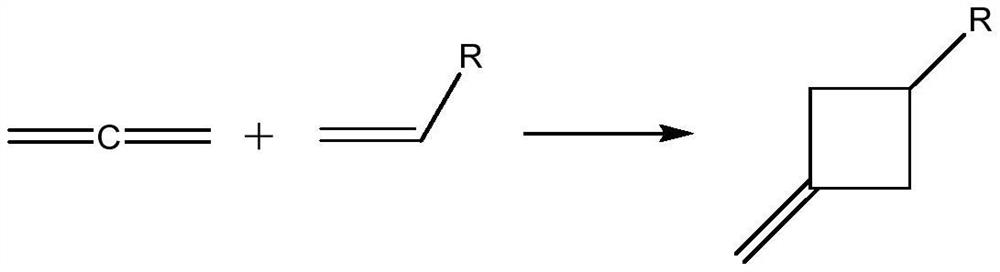

Preparation method of 3-methylene cyclobutyl derivative

A technology of methylenecyclobutyl derivatives, which is applied in the field of preparation of 3-methylenecyclobutyl derivatives, can solve problems such as difficulty in equipment cleaning, easy polymerization of propylene derivatives, safety risks, etc. The product conversion rate and the effect of safe and controllable reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The preparation of embodiment 1 3-methylene cyclobutylcarbonitrile

[0017] Dissolve acrylonitrile (3.71kg, 69.9mol, 3.5eq.), 4-methoxyphenol (24.8g, 0.20mol, 0.01eq.) in N-methylpyrrolidone (8800g), and cool down to 10-15°C , feed propadiene (800g, 20.0mol, 1.0eq.), and keep warm at about 10°C.

[0018] The continuous reactor (stainless steel tubular reactor with an inner diameter of 6mm and effective volume of 380mL) is set at a temperature of 250°C for the heat-conducting oil, and the configured solution enters the continuous reactor at a rate of 5.43mL / min with a plunger pump, and the system pressure 5.5MPa, the residence time is 70 minutes, and the material is discharged after being cooled by water. The reaction solution was distilled with a thorn column (20cm), the fractions were combined, water (1600mL) and MTBE (8000mL) were added, the liquid was stirred and separated, the organic phase was washed twice with water (1600mL), and 1414g of a colorless liquid was o...

Embodiment 2

[0019] Example 2 Preparation of 3-methylenecyclobutane-1-carboxylic acid methyl ester

[0020] Dissolve methyl acrylate (6.02kg, 70.0mol, 3.5eq.), 4-methoxyphenol (124g, 1.0mol, 0.05eq.) in N-methylpyrrolidone (8800g), and cool down to 10-15°C , feed propadiene (800g, 20.0mol, 1.0eq.), and keep warm at about 10°C.

[0021] The continuous reactor (stainless steel tubular reactor with an inner diameter of 6mm, effective volume of 300mL) is set at 250°C for the heat transfer oil, and the prepared solution enters the continuous reactor at a rate of 4.29mL / min with a plunger pump, and the system pressure 5.5MPa, the residence time is 70 minutes, and the material is discharged after being cooled by water. The reaction solution was distilled with a thorn column (20cm), the fractions were combined, water (1600mL) and MTBE (8000mL) were added, the liquid was stirred and separated, the organic phase was washed twice with water (1600mL), and 1765g of light yellow oil was precipitated. ...

Embodiment 3

[0022] Example 3 Preparation of ethyl 3-methylenecyclobutane-1-carboxylate

[0023] Dissolve ethyl acrylate (3.0kg, 30.0mol, 1.5eq.), 4-methoxyphenol (124g, 1.0mol, 0.05eq.) in N-methylpyrrolidone (8800g), and cool down to 10-15°C , feed propadiene (800g, 20.0mol, 1.0eq.), and keep warm at about 10°C.

[0024] The continuous reactor (stainless steel tubular reactor with an inner diameter of 6mm and an effective volume of 300mL) is set at a temperature of 250°C for the heat-conducting oil, and the configured solution enters the continuous reactor at a speed of 5mL / min with a plunger pump, and the system pressure is 5.5 MPa, the residence time is 60 minutes, and the material is discharged after being cooled by water. The reaction solution was distilled with a thorn column (20cm), the fractions were combined, water (1600mL) and MTBE (8000mL) were added, the liquid was stirred and separated, the organic phase was washed twice with water (1600mL), and 1820g of light yellow oil was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com