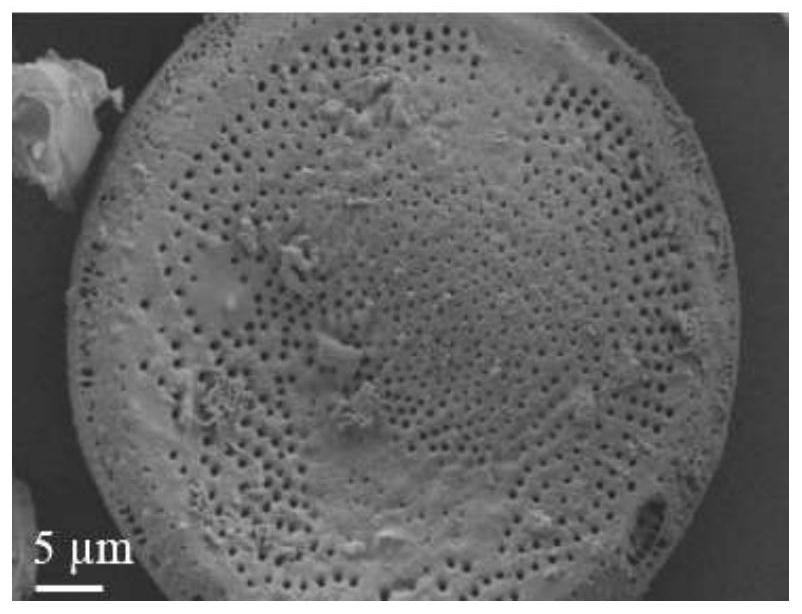

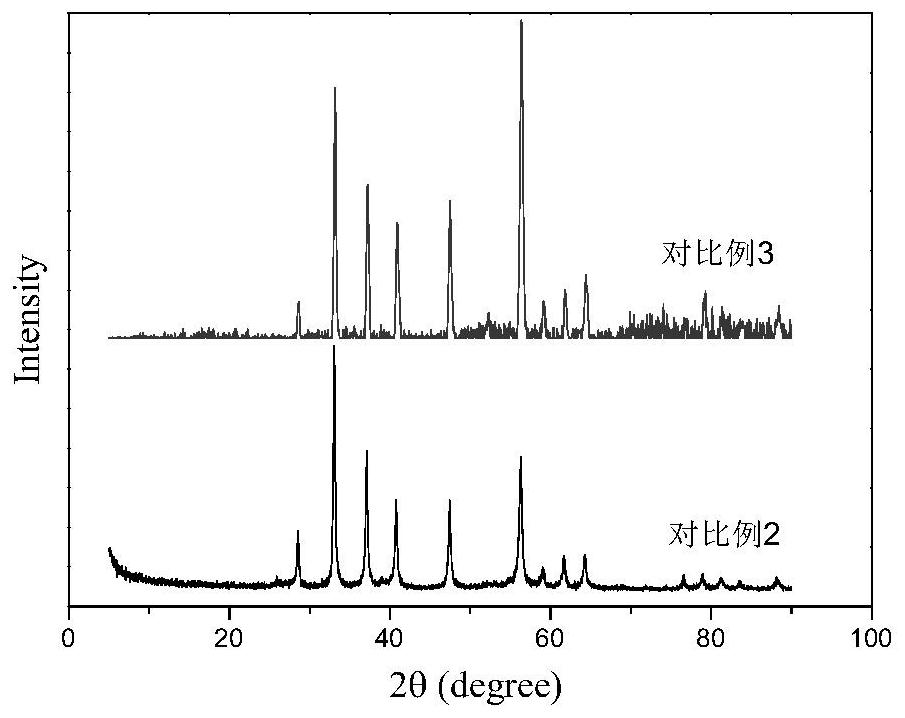

Diatomite-surface cobalt doped nano pyrite composite material and preparation and application thereof

A composite material and diatomite technology, applied in the preparation/separation of ammonia, catalyst activation/preparation, ammonia compounds, etc., can solve the problem of low visible light absorption rate of catalysts, easy recombination of photogenerated electrons and holes, hindering industrial applications, etc. problem, to achieve the effect of easy control, slow composite speed and wide light response range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

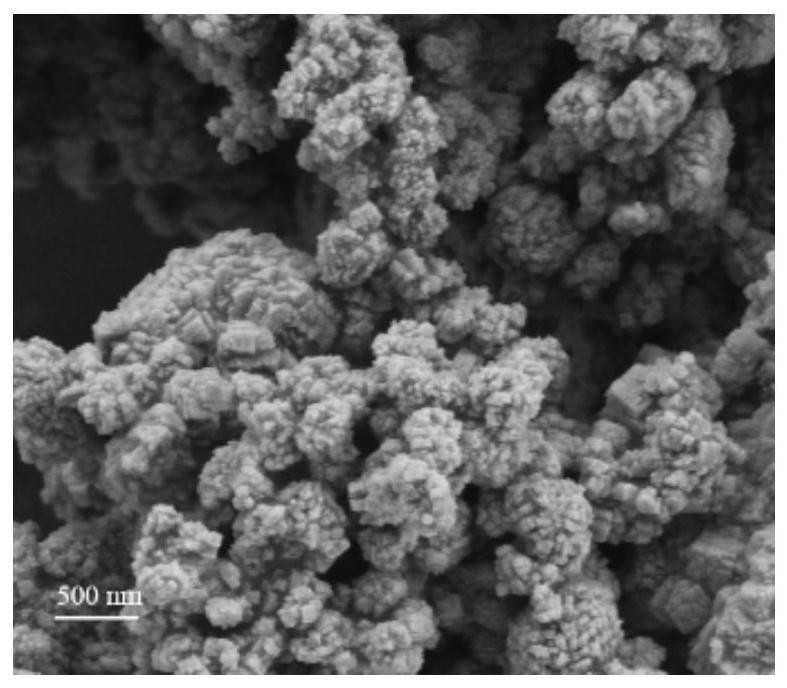

[0038] (1) Weigh FeSO 4 ·7H 2 O,Na 2 S 2 o 3 Each 13.9g, 7.9g, add 30ml of ethylene glycol, after ultrasonic (120w) stirring for 15 minutes, add 0.8g of sulfur powder, ultrasonic (120w) stirring for 30 minutes;

[0039](2) Transfer the solution in (1) to a reaction kettle, put it into a blast drying oven, and conduct a hydrothermal reaction at 180°C for 24 hours, with a heating rate of 8°C / min; after the reaction is completed, use dilute sulfuric acid, carbon disulfide, and Water, ethanol and distilled water were washed 3 times each, and the precipitate was collected by centrifugation after each washing; after the washing was completed, the collected precipitate was put into a vacuum drying oven and dried at 70°C for 10 h to obtain FeS 2 Nano powder;

[0040] (3) Cobalt sulfate is dissolved in 10ml ethylene glycol (solid-to-liquid ratio Co 2+ : Ethylene glycol=0.45%), by mass ratio Co 2+ :FeS 2 =5% FeS added in (2) 2 Nano powder, and by mass ratio diatomaceous earth: ...

Embodiment 2

[0044] (1) Weigh FeSO 4 ·7H 2 O,Na 2 S 2 o 3 Each 13.9g, 7.9g, add 30ml of ethylene glycol, after ultrasonic (120w) stirring for 15 minutes, add 0.8g of sulfur powder, ultrasonic (120w) stirring for 30 minutes;

[0045] (2) Transfer the solution in (1) to a reaction kettle, put it into a blast drying oven, and conduct a hydrothermal reaction at 180°C for 24 hours, with a heating rate of 8°C / min; after the reaction is completed, use dilute sulfuric acid, carbon disulfide, and Water, ethanol and distilled water were washed 3 times each, and the precipitate was collected by centrifugation after each washing; after the washing was completed, the collected precipitate was put into a vacuum drying oven and dried at 70°C for 10 h to obtain FeS 2 Nano powder;

[0046] (3) Cobalt sulfate is dissolved in 10ml ethylene glycol (solid-to-liquid ratio Co 2+ : Ethylene glycol=0.45%), by mass ratio Co 2+ :FeS 2 =5% FeS added in (2) 2 Nano powder, and by mass ratio diatomaceous earth:...

Embodiment 3

[0050] (1) Weigh FeSO 4 ·7H 2 O,Na 2 S 2 o 3 Each 13.9g, 7.9g, add 30ml of ethylene glycol, after ultrasonic (120w) stirring for 15 minutes, add 0.8g of sulfur powder, ultrasonic (120w) stirring for 30 minutes;

[0051] (2) Transfer the solution in (1) to a reaction kettle, put it into a blast drying oven, and conduct a hydrothermal reaction at 180°C for 24 hours, with a heating rate of 8°C / min; after the reaction is completed, use dilute sulfuric acid, carbon disulfide, and Water, ethanol and distilled water were washed 3 times each, and the precipitate was collected by centrifugation after each washing; after the washing was completed, the collected precipitate was put into a vacuum drying oven and dried at 70°C for 10 h to obtain FeS 2 Nano powder;

[0052] (3) Cobalt sulfate is dissolved in 10ml ethylene glycol (solid-to-liquid ratio Co 2+ : Ethylene glycol=0.45%), by mass ratio Co 2+ :FeS 2 =5% FeS added in (2) 2 Nano powder, and by mass ratio diatomaceous earth:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com