High-strength self-cleaning reflective film and preparation method thereof

A self-cleaning, reflective film technology, applied in the field of reflective film, can solve the problems of unstable metal reflective coating process control, easy aging of reflective film, etc., to achieve the effect of enhanced self-cleaning, tight fit, and rich source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

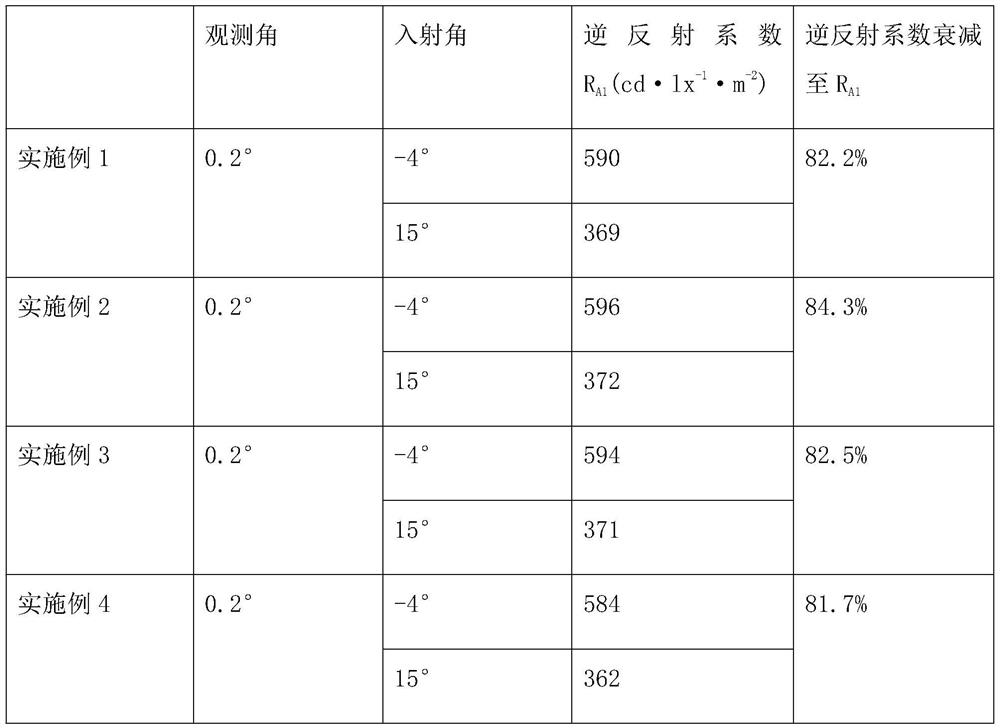

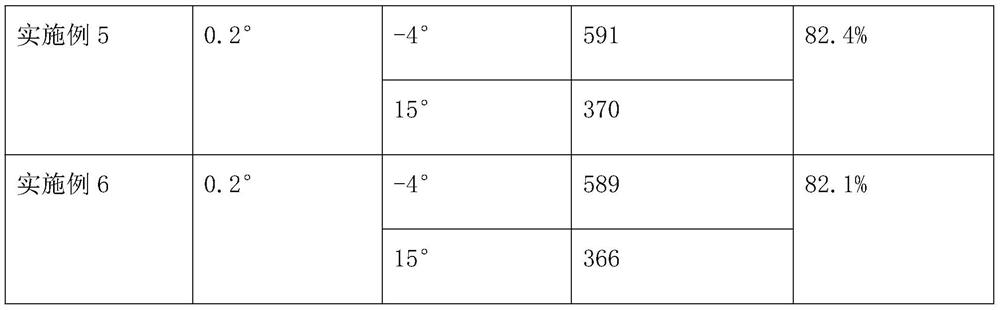

Examples

Embodiment 1

[0044] S1: Preparation of transparent support layer

[0045] Water-based polyurethane resin is selected as the transparent support layer;

[0046] S2: Preparation of glass bead layer

[0047] (1) glass beads are washed, dried and screened;

[0048](2) Use distilled water and ethanol to configure ethanol solvent in a ratio of 1:7, add oxalic acid to adjust the pH of the solvent to 3, add silane coupling agent, sodium dodecylsulfonate, ethyl cellulose, dimethyl Silicone oil; according to the content of silane coupling agent in the modified solvent is 4%, the content of sodium dodecylsulfonate in the modified solvent is 1%, the content of ethyl cellulose in the modified solvent is 3%, dimethyl The base silicone oil content in the modified solvent is ultrasonically dispersed at 1%, and stirred at 65°C for 4 hours to obtain the modified solvent;

[0049] (3) Add glass microbeads to the modified solvent, stir at 65°C after ultrasonic dispersion to obtain a mixed solution, cool to...

Embodiment 2

[0062] S1: Preparation of transparent support layer

[0063] Water-based polyurethane resin is selected as the transparent support layer;

[0064] S2: Preparation of glass bead layer

[0065] (1) glass beads are washed, dried and screened;

[0066] (2) Prepare ethanol solvent with distilled water and ethanol according to the ratio of 1:8, add oxalic acid to adjust the pH of the solvent to 4, add silane coupling agent, sodium dodecylsulfonate, ethyl cellulose, dimethyl Silicone oil; according to the content of silane coupling agent in the modified solvent is 6%, the content of sodium dodecylsulfonate in the modified solvent is 2%, the content of ethyl cellulose in the modified solvent is 8%, dimethyl The base silicone oil content in the modified solvent is 2% ultrasonically dispersed, stirred at 70°C for 5 hours to obtain the modified solvent; cooled to 19°C and filtered;

[0067] (3) Add glass microbeads to the modified solvent, stir at 70°C after ultrasonic dispersion to o...

Embodiment 3

[0080] S1: Preparation of transparent support layer

[0081] Water-based polyurethane resin is selected as the transparent support layer;

[0082] S2: Preparation of glass bead layer

[0083] (1) glass beads are washed, dried and screened;

[0084] (2) Prepare ethanol solvent with distilled water and ethanol according to the ratio of 1:9, add tartaric acid to adjust the pH of the solvent to 6, add silane coupling agent, sodium dodecylsulfonate, ethyl cellulose, dimethyl Silicone oil; according to the content of silane coupling agent in the modified solvent is 18%, the content of sodium dodecylsulfonate in the modified solvent is 4%, the content of ethyl cellulose in the modified solvent is 3%, dimethyl The base silicone oil content in the modified solvent is 3%, ultrasonically dispersed, stirred at 80°C for 3 hours to obtain the modified solvent; cooled to 25°C and filtered;

[0085] (3) adding the glass microspheres of step S2(1) into the modified solvent of step S2(2), ul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com