Silicon carbide crystal growth method and equipment for supplementing gaseous carbon source and silicon source

A technology of crystal growth and gaseous carbon source, applied in the directions of crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of waste of raw materials, affecting the yield and product quality of downstream processes, affecting the quality of silicon carbide crystals, etc. Purity, avoid screw dislocation, improve the effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

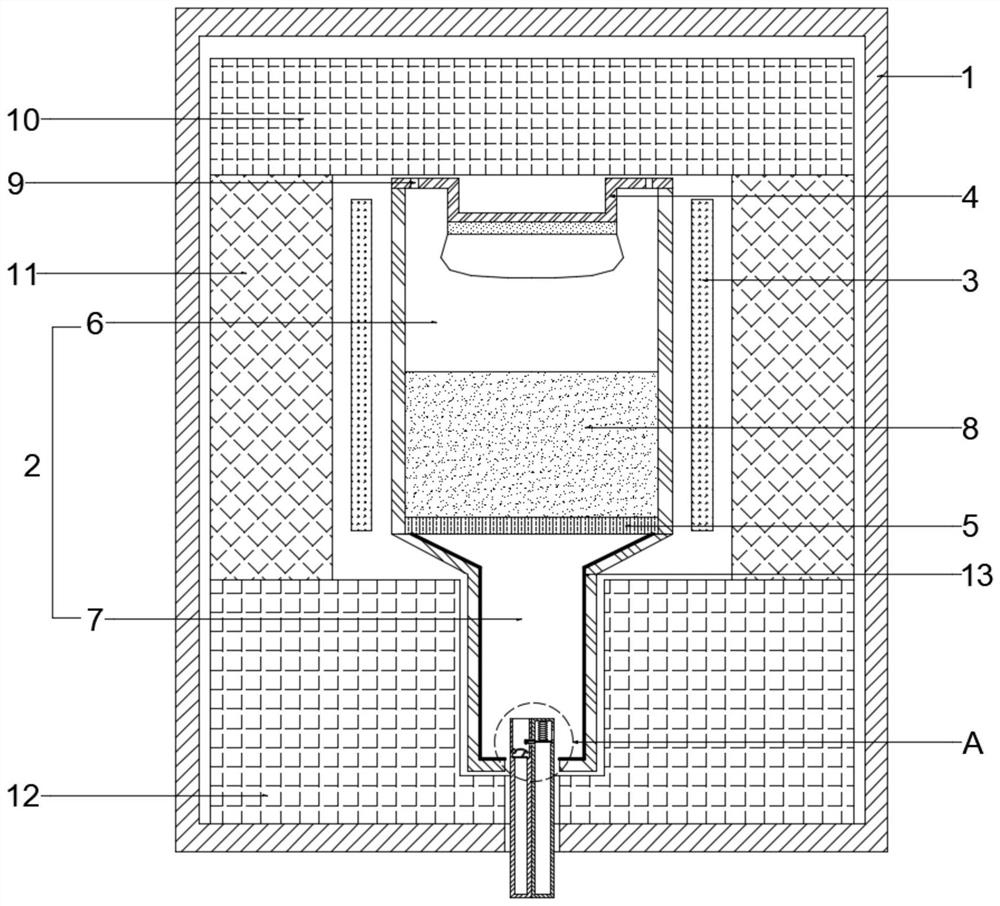

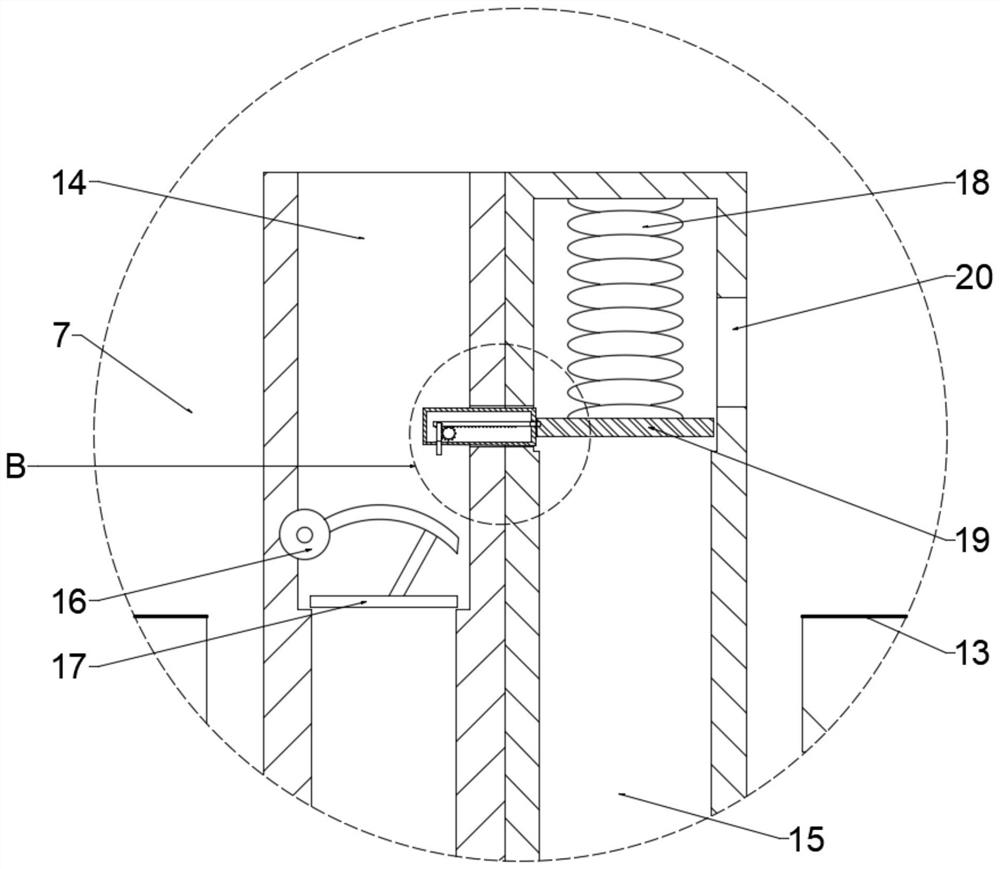

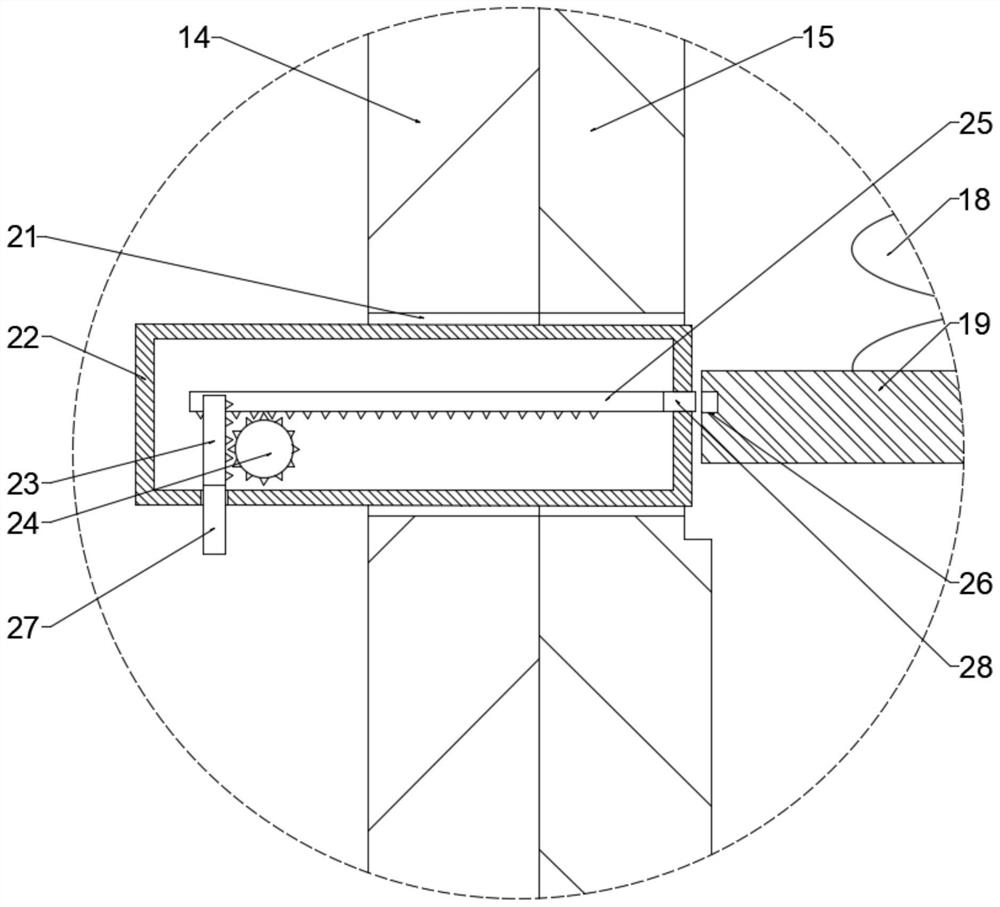

[0033] Such as figure 1 As shown, a silicon carbide crystal growth equipment supplementing gaseous carbon source and silicon source includes a furnace body 1, a graphite crucible 2 fixed in the furnace body 1, a heater 3, and a growth tank 4 arranged on the top of the graphite crucible 2, The graphite crucible 2 is horizontally provided with a porous partition 5, and the porous partition 5 divides the graphite crucible 2 into a crystal growth chamber 6 and a gas diffusion chamber 7. The height of the crystal growth chamber 6 is defined as M, and the crystal growth chamber 6 is used for Filled with silicon carbide raw material 8, the upper edge of the gas diffusion chamber 7 is set in the area from 1 / 3M above the porous partition 5 to the horizontal centerline of the porous partition 5. In this embodiment, the gas diffusion chamber 7 is integrally connected to Below the crystal growth chamber 6 , the bottom of the gas diffusion chamber 7 is fixedly connected with an intake asse...

Embodiment 2

[0041] Such as Figure 4 As shown, different from Embodiment 1, the upper edge position of the gas diffusion chamber 7 in this embodiment and Embodiment 1 is set differently. In Embodiment 1, the gas diffusion chamber 7 is integrally connected under the crystal growth chamber 6, that is, the gas diffusion chamber The upper edge of 7 is set at the horizontal centerline of the porous partition 5, and in this embodiment, the upper edge of the gas diffusion chamber 7 is set at a height of 1 / 8M above the porous partition 5 and surrounds the porous partition 5 and the bottom edge of the crystal growth chamber 6, the upper edge of the gas diffusion chamber 7 is set within the height of 1 / 3M above the porous partition plate 5, and the side walls of the surrounded crystal growth chamber 6 are provided with several The through holes with the same pore diameter of the separator 5 can make the gaseous carbon source and the gaseous silicon source supplement the silicon carbide raw material...

Embodiment 3

[0043] A method for growing silicon carbide crystals supplementing a gaseous carbon source and a silicon source, using the structure in Example 1, comprising the steps of:

[0044] S1. Preheating stage: fill the silicon carbide raw material 8 in the crystal growth chamber 6 of the graphite crucible 2, check the tightness of the furnace body 1, start the vacuum device (not shown) arranged at the bottom of the furnace body 1, Vacuumize until the pressure in the furnace body 1 is about 5 Pa, and further evacuate until the pressure in the furnace body 1 is at 10 Pa. -2 About Pa, adjust the heater 3 to make the temperature in the furnace body 1 reach about 500°C, and fill the furnace body 1 with a mixed gas of nitrogen and helium with a volume ratio of 1:5 to 1:20 through the air intake assembly to maintain the temperature of the furnace body. The pressure in the body 1 is about 10000Pa;

[0045] S2. The first stage of heating up: adjust the heater 3 to raise the temperature of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com