Multi-parameter gas sensing microchip, preparation method thereof and gas sensor

A gas sensing and microchip technology, applied in semiconductor/solid-state device parts, microstructure technology, gaseous chemical plating, etc., can solve the problems of low integration, low detection accuracy, single heating temperature, etc. The effect of reducing power consumption, reducing volume and improving integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

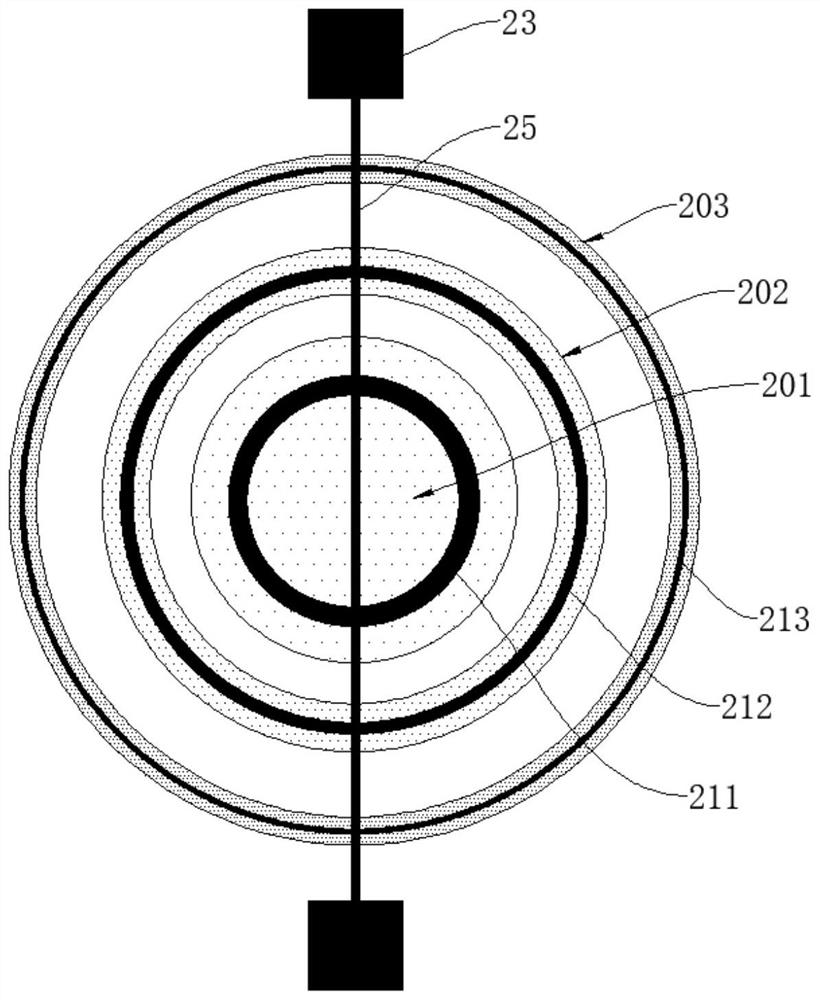

[0057] figure 2 It is a schematic structural diagram of the heating layer of the multi-parameter gas sensing microchip provided in Embodiment 1 of the present invention. like figure 2 As shown, the heating layer of the multi-parameter gas sensing microchip provided in this embodiment includes a heating electrode, and the heating electrode is a plurality of heating resistance wires with different cross-sectional areas, and the plurality of heating resistance wires form a plurality of heating elements. Area. The heating electrode includes a first heating resistance wire 211 , a second heating resistance wire 212 , and a third heating resistance wire 213 . The cross-sectional area of the first heating resistance wire 211 is larger than that of the second heating resistance wire 212 , and the cross-sectional area of the second heating resistance wire 212 is larger than that of the third heating resistance wire 213 . The first heating resistance wire 211 , the second heati...

Embodiment 2

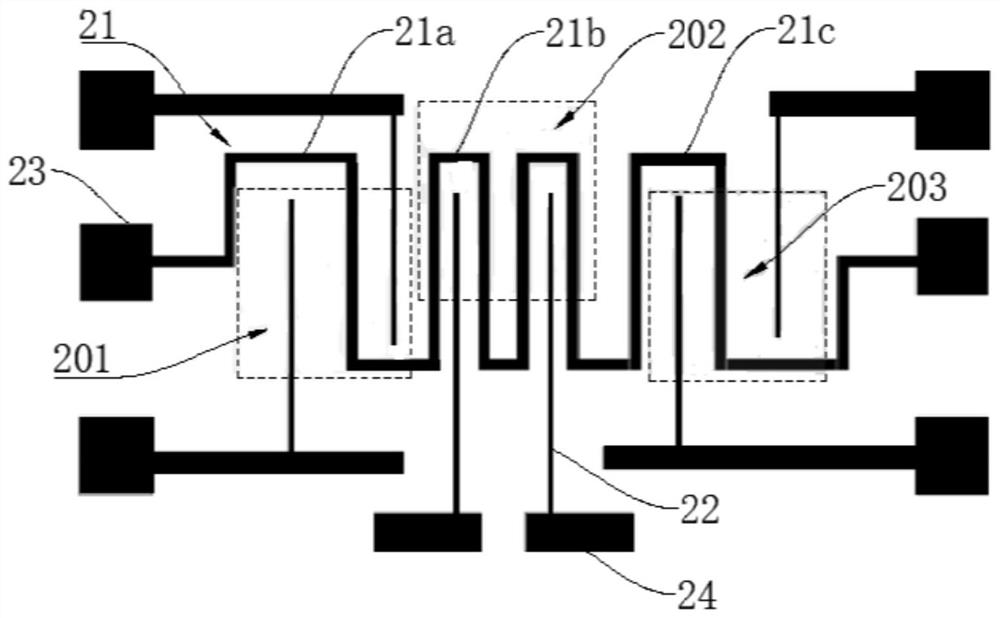

[0062] image 3 It is a schematic structural diagram of the heating layer of the multi-parameter gas sensing microchip provided in the second embodiment of the present invention. The heating layer of the multi-parameter gas sensing microchip provided in this embodiment includes a heating electrode 21, and the heating electrode 21 is a heating resistance wire having a plurality of segments with different cross-sectional areas, and the plurality of segments of the heating resistance wire A plurality of said heating zones are formed. like image 3 As shown, the heating resistance wire includes a first segment resistance wire 21a, a second segment resistance wire 21b, a third segment resistance wire 21c, the first segment resistance wire 21a forms the first heating zone 201, and the second segment resistance wire 21a The segmented resistance wire 21 b forms the second heating zone 202 , and the third segmented resistance wire 21 c forms the third heating zone 203 . The heating ...

Embodiment 3

[0066] Image 6 It is a flow chart of the preparation method of the multi-parameter gas sensing microchip provided in the third embodiment of the present invention. refer to figure 1 and Image 6 , the preparation method of the multi-parameter gas sensing microchip provided in this embodiment comprises the following steps:

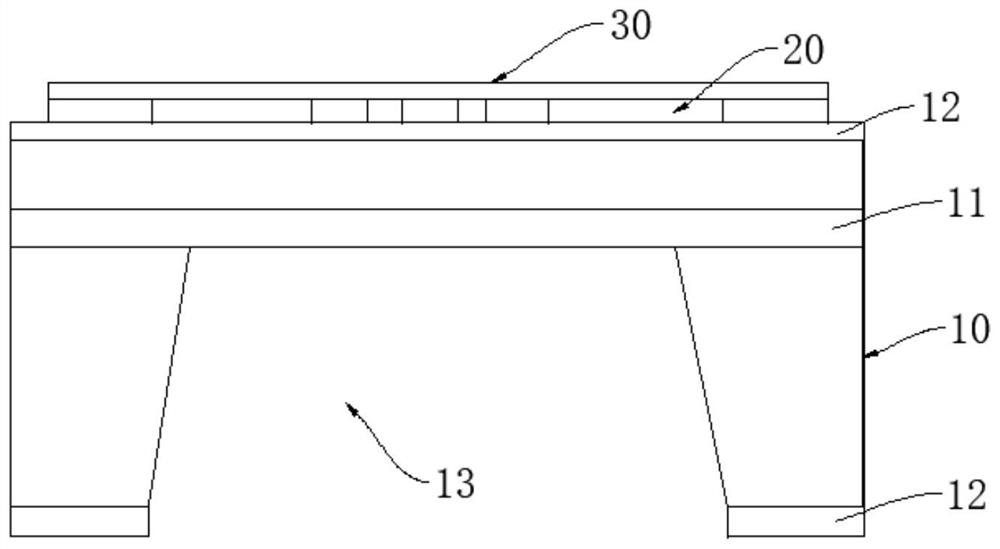

[0067]S1) Provide a silicon-based substrate 10 .

[0068] The silicon-based substrate 10 adopts an SOI wafer layer having p-type boron-doped silicon (Si), and the SOI (Silicon-On-Insulator, i.e., silicon on an insulating substrate) silicon wafer refers to the silicon wafer between the top layer silicon and the back substrate. A buried oxide layer (BOX) is introduced as a supporting layer 11, and a silicon oxide or silicon nitride thin film layer 12 with a thickness not greater than 1 μm is coated on the front and back of the silicon wafer by plasma enhanced chemical vapor deposition.

[0069] S2) Fabricate a heating layer 20 having multiple heating reg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Section thickness | aaaaa | aaaaa |

| Section width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com