Silicon dioxide-based aerogel, composite material containing same, and preparation method and application of composite material

A silica and gel technology, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve the problems of inability to obtain products with special complex structures, limit the application of silica aerogel, etc., and achieve high integrity , good mechanical properties, high specific surface area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] A certain amount of tetraethyl orthosilicate (TEOS) was added dropwise to a mixed solution of absolute ethanol and 0.1 mol / L hydrochloric acid in an equimolar ratio, and magnetically stirred at room temperature for 24 hours to carry out sufficient acid-catalyzed hydrolysis condensation. After the reaction is completed, a certain proportion of coupling agent methacrylate propyl trimethoxysilane (MPTS) is added dropwise to the above solution, and magnetic stirring is continued at room temperature for 24 hours to form a resin solution. The configuration ratio and mass fraction of TEOS and MPTS in the above solution are given in Table 1:

[0069] Table 1

[0070]

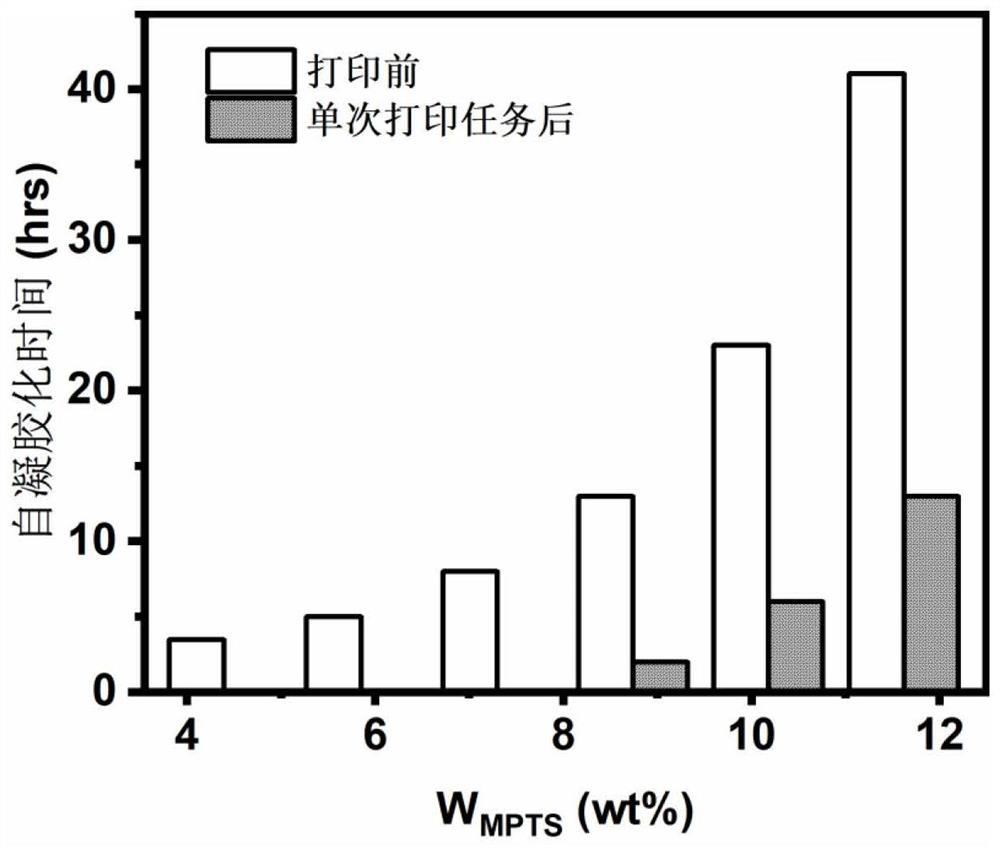

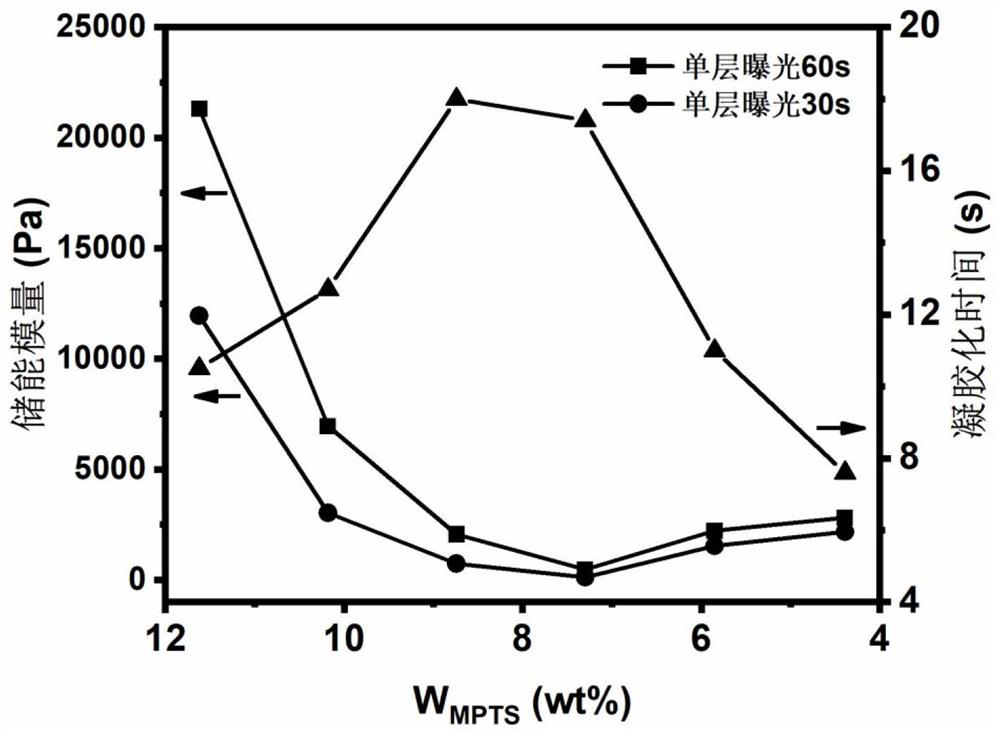

[0071] Add 1wt% urotropine and 5wt% photoinitiator (2,4,6-trimethylbenzoyl) diphenylphosphine oxide to the above resin solution, stir until clear and transparent, then pour it into the photocuring 3D printer feed tank . Use the computer CAD software to export the three-dimensional structure model stl. format...

Embodiment 2

[0077] Follow V TEOS / V MPTS =23 / 7 ratio to prepare the resin solution, the solution preparation process and the photocuring 3D printing preparation process are the same as in Example 1. After the printing is completed, place the printed wet gel in the resin solution adding 1wt% urotropine, and place it under a light intensity of 20mW / cm 2 2-3 hours of light under the light source with a wavelength of 405nm. Then the obtained gel was packaged in a hydrothermal kettle and aged at 100°C for 3-4 days. The aged gel was subjected to 6 solvent replacements with absolute ethanol and n-hexane, and then the gel was hydrophobically modified with trimethylchlorosilane (TMCS), dried quickly under normal pressure, and the volume shrinkage was negligible. Complete airgel parts.

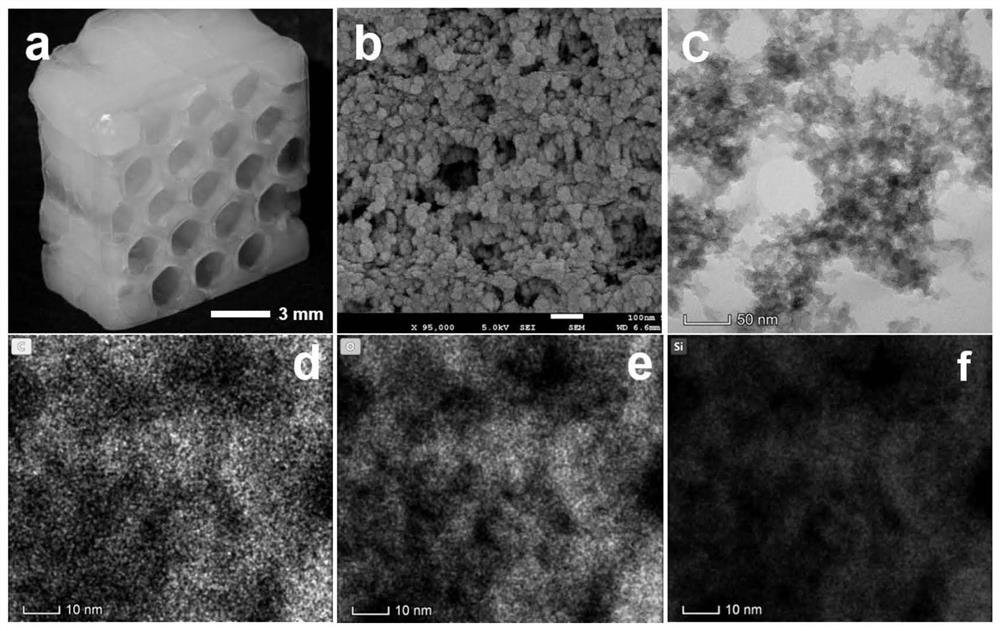

[0078] image 3 A-f in this example are the optical photos, SEM photos, TEM photos and EDS elemental analysis surface images of the photocured 3D printed silica-based airgel obtained in this example. image 3 I...

Embodiment 3

[0083] A sheet-like airgel with a thickness of 3 mm was prepared by printing according to Example 2. Fix the 3mm thick silica airgel with a metal bracket and place it horizontally above the flame to ensure that the outer flame of the flame touches the center of the bottom of the airgel, and perform an ablation test on it.

[0084] Figure 7 In the infrared thermal image shown in the figure, under the continuous 20s ablation of the outer flame at about 500°C, the 3mm thick 3D printed silica airgel showed good low conductivity and fire resistance; The temperature on the upper surface of the gel was only 96°C; when the flame left after 20s, the airgel did not continue to burn, and the surface temperature was only 140°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com