Preparation method for extracting total flavonoids from peony flowers

A technology of peony flower and total flavonoids, which is applied in skin care preparations, medical preparations containing active ingredients, and pharmaceutical formulas, etc. It can solve the problem of high extraction bottle placement requirements, unfavorable large-scale production, and the impact of peony flavonoid activity and other problems, to achieve the effect of being suitable for large-scale production, easy to operate, and good extraction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

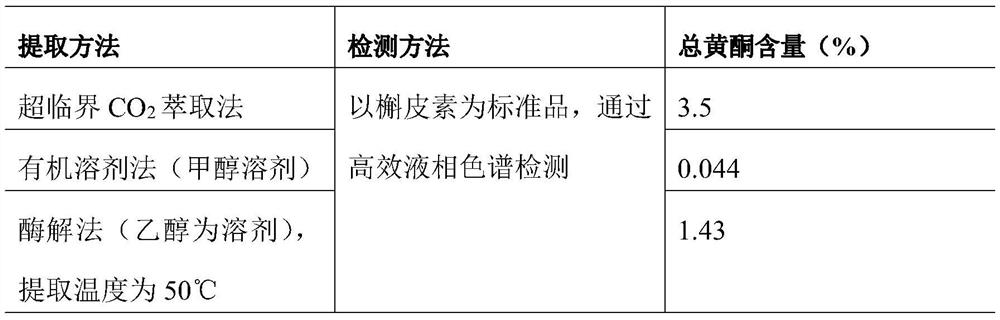

Image

Examples

Embodiment 1

[0024] A preparation method for extracting total flavonoids from peony flowers, comprising the following steps:

[0025] S1, take the dried peony flower, remove impurities, pulverize, and obtain the peony flower powder as product A;

[0026] S2, mix product A and 1,3-propanediol with a mass ratio of 10:1-20:1 to obtain product B;

[0027] S3. Pass product B through supercritical CO 2 extraction, initial extraction, CO 2 The flow rate is 8-12L / h, the extraction pressure is 25-35MPa, the extraction temperature is 30-32℃, and the extraction time is 8-12min; then increase the CO 2 The flow rate is increased to 20-30L / h, the extraction pressure is increased to 45-55MPa at a rate of 0.3-0.6MPa per minute, the extraction temperature is kept at 30-32°C, and the extraction time is 45-55min to obtain C product;

[0028] S4. Separate product C, the separation pressure is reduced to 2-8MPa at a rate of 0.4-0.6MPa per minute, and the separation temperature is 25-30°C to obtain a finishe...

Embodiment 2

[0030] A preparation method for extracting total flavonoids from peony flowers, comprising the following steps:

[0031] S1, take the dried peony flower, remove impurities, pulverize and pass through a 40-50 mesh sieve, and obtain the peony flower powder as product A;

[0032] S2, mix product A and 1,3-propanediol with a mass ratio of 10:1 to obtain product B;

[0033] S3. Pass product B through supercritical CO 2 extraction, initial extraction, CO 2 The flow rate is 8L / h, the extraction pressure is 25MPa, the extraction temperature is 30℃, and the extraction time is 8min; then increase the CO 2 The flow rate was increased to 20L / h, the extraction pressure was increased to 45MPa at a rate of 0.3MPa per minute, the extraction temperature was kept at 30°C, and the extraction time was 45min to obtain C product;

[0034] S4. Separate product C, the separation pressure is reduced to 8MPa at a rate of 0.4MPa per minute, and the separation temperature is 25°C to obtain a finished ...

Embodiment 3

[0036] A preparation method for extracting total flavonoids from peony flowers, comprising the following steps:

[0037] S1, get the dried peony flower, remove impurities, pulverize and pass through a 50-mesh sieve, and obtain the peony flower powder as product A;

[0038] S2. Mix product A and 1,3-propanediol with a mass ratio of 15:1 to obtain product B;

[0039] S3. Pass product B through supercritical CO 2 extraction, initial extraction, CO 2 The flow rate is 12L / h, the extraction pressure is 35MPa, the extraction temperature is 32℃, and the extraction time is 12min; then increase the CO 2 The flow rate was increased to 30L / h, the extraction pressure was increased to 55MPa at a rate of 0.6MPa per minute, the extraction temperature was kept at 32°C, and the extraction time was 55min to obtain C product;

[0040] S4. Separate product C, the separation pressure is reduced to 2MPa at a rate of 0.6MPa per minute, and the separation temperature is 30°C to obtain a finished pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com