Preparation method of halloysite nanotube-surfactant composite intercalated montmorillonite fluid loss reducer for drilling fluid

A technology of halloysite nanotubes and surfactants, applied in nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve problems such as poor temperature resistance, and improve the degree of peeling and nanotechnology High and improve the effect of fluid loss reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

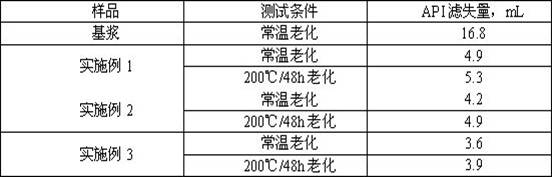

Examples

Embodiment 1

[0042] 1) Preparation of pre-intercalated halloysite nanotubes: (1) 800g halloysite nanotubes, 1000g deionized water and 30g NaOH were added to the high pressure reactor, and the alkalization reaction was carried out for 30min; (2) in the above reactor Add 20g potassium chloride and 30g sodium tetradecyl sulfonate in turn, raise the temperature of the system to 60°C, and perform a pre-intercalation reaction for 60min under the condition that the rotating speed is 2000rpm; (3) after the reaction is completed, turn the above system to 60°C. Put it into a vacuum filter press, filter it three times, wash it three times with deionized water, remove all the solvent, and further remove the remaining solvent by a rotary evaporator, and the obtained powder is the pre-intercalated halloysite nanotube.

[0043]2) Preparation of halloysite nanotube-surfactant composite intercalated montmorillonite fluid loss reducer for drilling fluid: (1) 1200g montmorillonite, 3000g deionized water and 3...

Embodiment 2

[0045] 1) Preparation of pre-intercalated halloysite nanotubes: (1) 1000g halloysite nanotubes, 1200g deionized water and 40g NaOH were added to the high pressure reactor, and the alkalization reaction was carried out for 40min; (2) in the above reactor Add 25g potassium chloride and 40g sodium hexadecyl sulfonate in turn, raise the temperature of the system to 70°C, and perform a pre-intercalation reaction for 80min under the condition that the rotating speed is 2000rpm; (3) after the reaction is completed, turn the above system into Put it into a vacuum filter press, filter it three times, wash it three times with deionized water, remove all the solvent, and further remove the remaining solvent by a rotary evaporator, and the obtained powder is the pre-intercalated halloysite nanotube.

[0046] 2) Preparation of halloysite nanotube-surfactant composite intercalated montmorillonite fluid loss reducer for drilling fluid: (1) 1350g montmorillonite, 4000g deionized water and 40 N...

Embodiment 3

[0048] 1) Preparation of pre-intercalated halloysite nanotubes: (1) 1200g halloysite nanotubes, 1500g deionized water and 50g NaOH were added to the high pressure reactor, and the alkalization reaction was carried out for 50min; (2) in the above reactor Add 30g potassium chloride and 50g sodium octadecyl sulfonate in turn, raise the temperature of the system to 80°C, and perform a pre-intercalation reaction for 90min under the condition that the rotating speed is 2000rpm; (3) after the reaction, turn the above system into Put it into a vacuum filter press, filter it three times, wash it three times with deionized water, remove all the solvent, and further remove the remaining solvent by a rotary evaporator, and the obtained powder is the pre-intercalated halloysite nanotube.

[0049] 2) Preparation of halloysite nanotube-surfactant composite intercalated montmorillonite fluid loss reducer for drilling fluid: (1) 1500g montmorillonite, 5000g deionized water and 50 NaOH were sequ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com