Recyclable flexible titanium dioxide/pyrolytic carbon/carbon fiber felt composite photocatalytic material as well as preparation method and application thereof

A technology of composite photocatalysis and carbon fiber mat, which is applied in the field of photocatalysis materials, can solve the problems of low solar energy utilization and difficult recycling, and achieve the effects of reducing electron-hole recombination, low cost, and promoting uniform growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

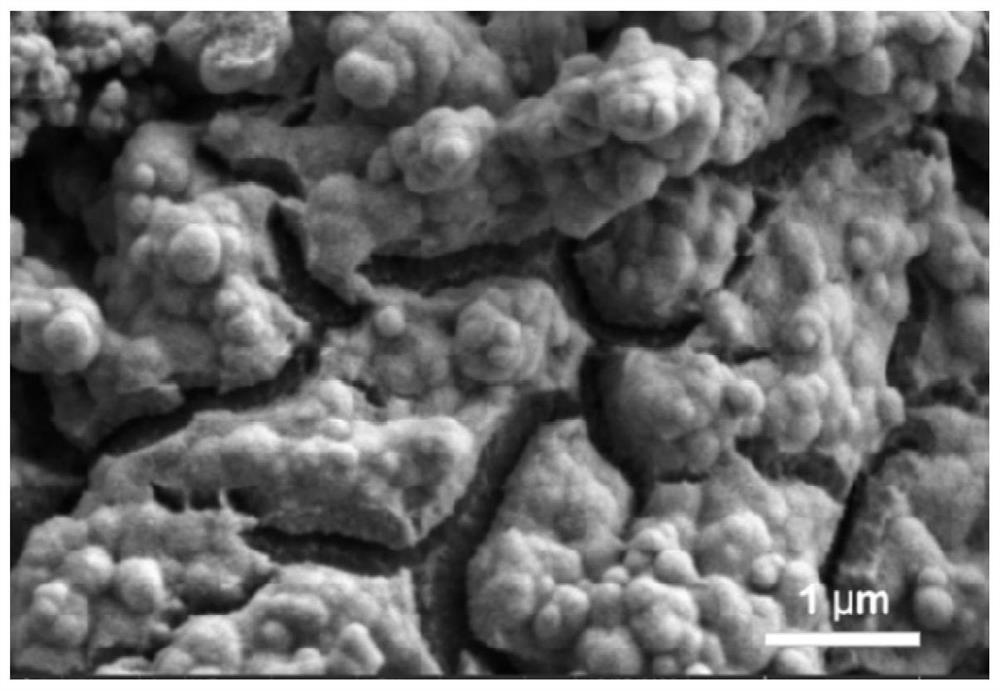

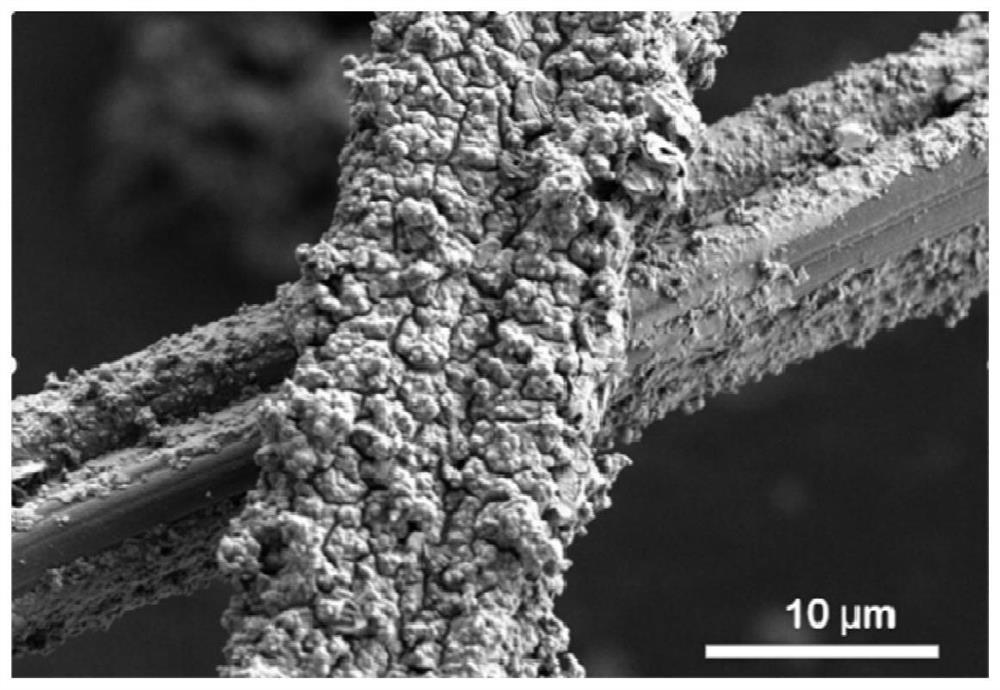

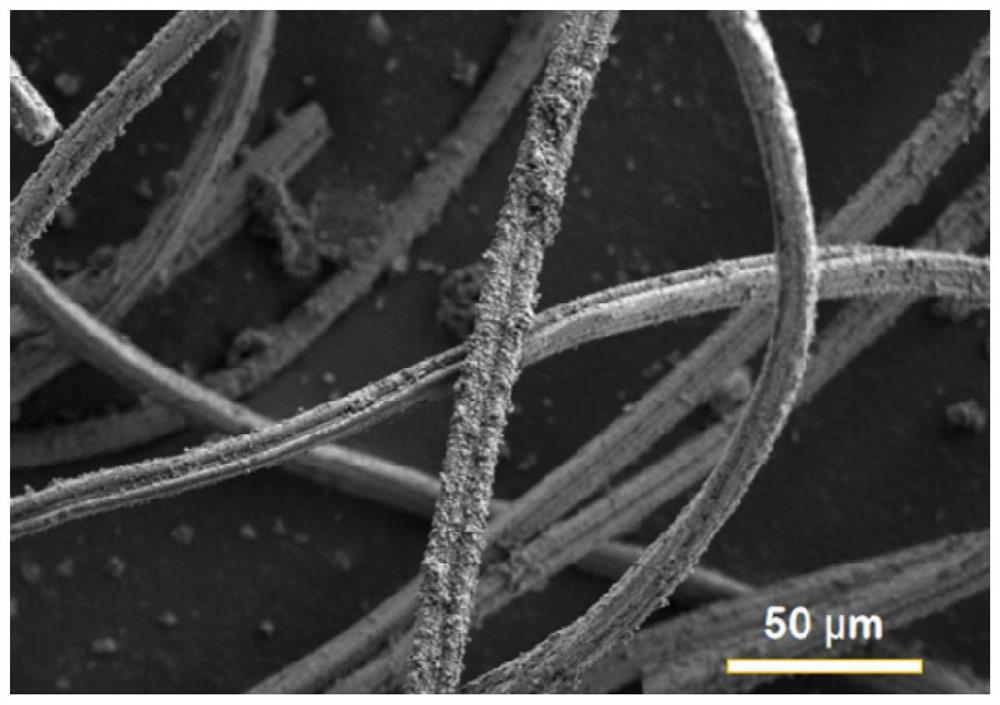

[0027] The invention discloses a recyclable flexible titanium dioxide (TiO 2 ) / pyrolytic carbon / carbon fiber felt composite photocatalytic material preparation method, comprising the following steps: first soak the carbon fiber felt in acetone for pretreatment, obtain a clean carbon fiber felt after drying, put the gained clean carbon fiber felt into a CVD tube In the furnace, pyrolytic carbon is deposited at high temperature by feeding methane and argon to obtain pyrolytic carbon / carbon fiber felt. A certain amount of tetrabutyl titanate is added to the mixed solution of acetone and ethylene glycol, and pyrolytic carbon / carbon fiber felt is The carbon fiber felt is added to the reactor lined with polytetrafluoroethylene, and the recyclable flexible TiO is obtained after cleaning and drying. 2 / pyrolytic carbon / carbon fiber felt composite photocatalytic material. Specific steps are as follows:

[0028] Step 1: Soak the carbon fiber felt in acetone for 12 hours and dry to obt...

Embodiment 1

[0040] (1) Soak the carbon fiber felt in acetone for 12 hours, remove some impurities on the surface, and dry to obtain a clean carbon fiber felt.

[0041] (2) Put the clean carbon fiber felt pretreated with acetone into a CVD tube furnace, flow argon at 150-300mL / min and heat it at 8°C per minute to 1000°C in an argon atmosphere.

[0042] (3) When the furnace is kept warm, feed methane at a flow rate of 50-100mL / min to form a mixed gas of methane: argon at a ratio of 1:3 and feed methane and argon at a temperature of 1000°C for 10 minutes, then cool down naturally. A pyrolytic carbon / carbon fiber felt is obtained.

[0043] (4) Add ethylene glycol, acetone, and tetrabutyl titanate into a beaker at a volume ratio of 20:10:1, and stir for 30 minutes to obtain a prepared solution.

[0044] (5) Put the pyrolytic carbon / carbon fiber mat obtained in step (3) and the solution prepared in step (4) into a polytetrafluoroethylene reactor for hydrothermal reaction, react at 150°C for 16...

Embodiment 2

[0047] (1) Soak the carbon fiber felt in acetone for 12 hours, remove some impurities on the surface, and dry to obtain a clean carbon fiber felt.

[0048] (2) Put the clean carbon fiber felt pretreated with acetone into a CVD tube furnace, flow argon at 150-300mL / min, and heat it at 9°C to 1100°C per minute in an argon atmosphere.

[0049] (3) When the furnace is kept warm, feed methane at a flow rate of 50-100mL / min to form a mixed gas of methane: argon at a ratio of 1:3, and deposit at 1000°C for 20 minutes, then cool down naturally. A pyrolytic carbon / carbon fiber felt is obtained.

[0050] (4) Add ethylene glycol, acetone, and tetrabutyl titanate into a beaker at a volume ratio of 20:10:1, and stir for 30 minutes to obtain a prepared solution.

[0051] (5) Put the pyrolytic carbon / carbon fiber mat obtained in step (3) and the prepared solution in step (4) into a polytetrafluoroethylene reactor for hydrothermal reaction, react at 160°C for 12 hours, and collect the produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com