Method for solving cracks of head and tail blanks of 10Cr17 steel grade

A technology of head and tail, steel grade, applied in the field of solving 10Cr17 steel grade head and tail billet cracks, can solve problems such as reducing the yield of head and tail billets, affecting the use of head and tail billets, etc. Quality, the effect of eliminating the phenomenon of surface peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Step 1: Dephosphorization process: molten iron P: 0.075-0.150%, use lime powder and dephosphorization agent to dephosphorize, remove slag after dephosphorization, and after pretreatment, semi-steel P < 0.020%;

[0025] Step 2: TSR furnace smelting process: the addition of high-carbon ferrochrome is 20-30%, the dephosphorized semi-steel P 6 minutes, Cr after reduction: 16.0-17.5%, the amount of ferrosilicon added is 1-1.5% for reduction, the slag color after reduction is controlled to be white slag, and the secondary desulfurization process is adopted to strictly control the output Steel sulfur content, tapping sulfur content ≤ 0.006%;

[0026] Step 3: LF refining process: After the molten steel reaches LF, the thickness of the slag layer in the ladle is 150-300mm, the entering temperature is 1500-1620°C, the refining time is 45-120min, the power transmission time is 15-40min, and lime and fluorite are added to adjust the refining Alkalinity R > 2.0, soft blowing time, s...

Embodiment 2~3 and comparative example 1~8

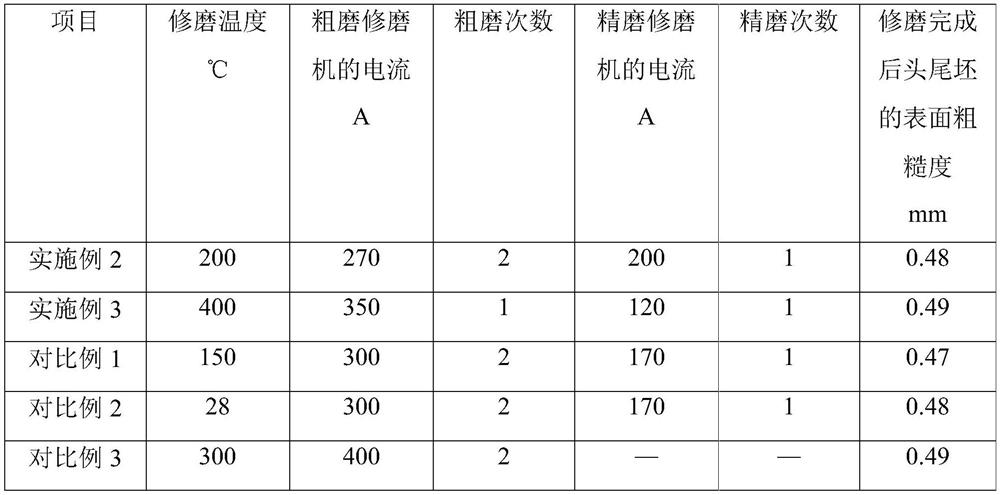

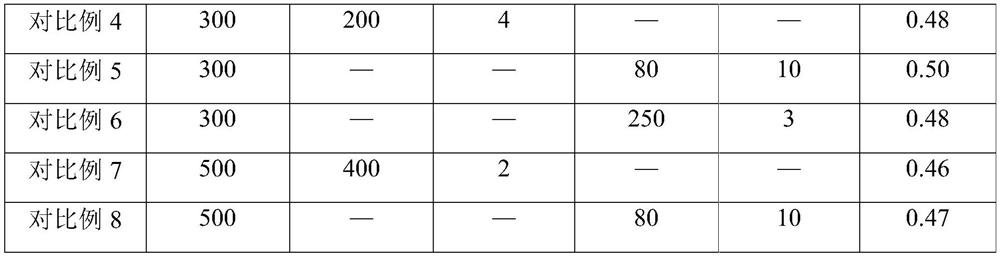

[0031] The grinding methods of Examples 2-3 and Comparative Examples 1-8 are the same as those of Example 1, the difference lies in the grinding temperature, the current of the grinding machine and the number of grinding times, see Table 1 for details.

[0032] Table 1

[0033]

[0034]

[0035] During the grinding process of Examples 1 to 3 and Comparative Examples 1 to 8, the grinding rate of the head and tail blanks after the grinding is counted; and the finished head and tail blanks are hot-rolled and pickled to calculate the first-grade product rate; the results can be seen in Table 2.

[0036] Table 2

[0037] project Grinding rate% First grade rate% Example 1 2.6 100 Example 2 2.8 100 Example 3 2.7 100 Comparative example 1 4.3 73 Comparative example 2 4.8 66 Comparative example 3 4.3 96 Comparative example 4 4.2 94 Comparative example 5 4.2 90 Comparative example 6 4.0 94 Comparativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com