Wormwood powder shoe material and preparation method thereof

A technology of wormwood powder and shoe materials, which is applied in the field of shoe materials, can solve the problems of easy eczema on the feet, easy breeding of bacteria, easy wear and deformation, etc., and achieves simple and controllable preparation methods, good antibacterial and deodorizing effects, and hydrophobic The effect of resistance to hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

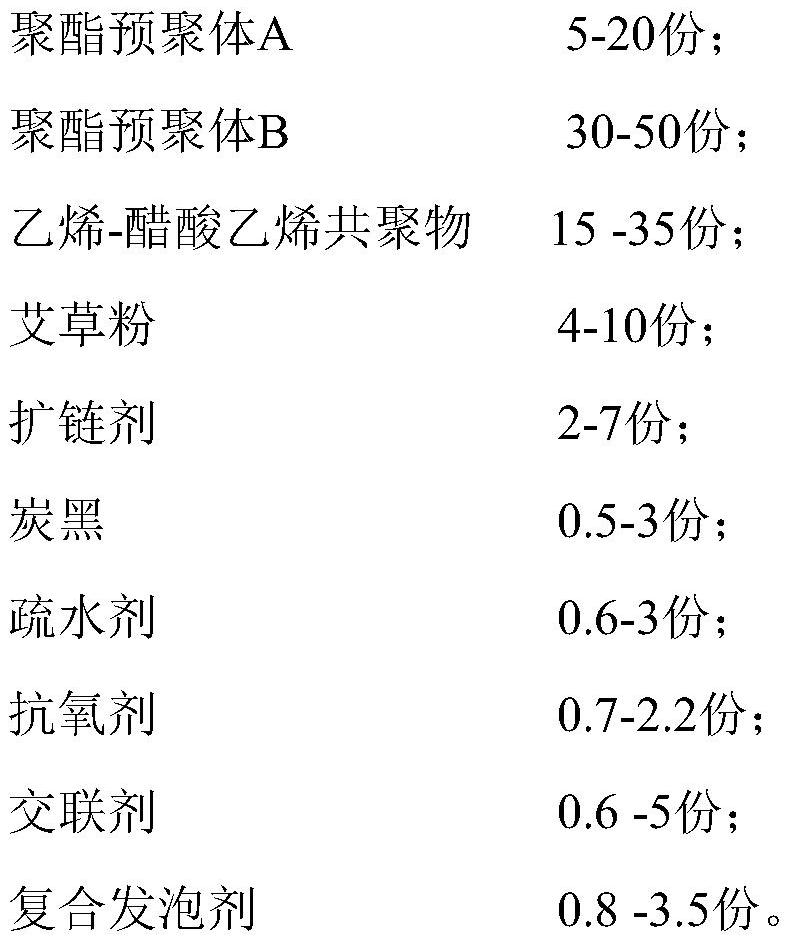

[0033] A kind of wormwood powder shoe material, comprises the raw material of following weight portion:

[0034]

[0035] In this embodiment, the preparation of the polyester prepolymer A includes the following steps: Weighing 1,4-butanediol and succinic acid with a molar ratio of 1.0:1 and mixing them uniformly, under normal pressure nitrogen protection conditions, After raising the temperature to 160°C and stirring for 1 hour, add catalyst A and antioxidant A, continue to raise the temperature to 200°C until almost no water is distilled out, and then gradually reduce the pressure to below 5kPa to carry out polycondensation reaction for 3 hours and then stop the reaction, that is The polyester prepolymer A was prepared.

[0036] The preparation of the polyester prepolymer B comprises the steps of: weighing a short-chain dibasic alcohol and an aliphatic saturated dibasic acid with an alkyd molar ratio of 1.0:1 and mixing them uniformly; After stirring and reacting at 160°C...

Embodiment 2

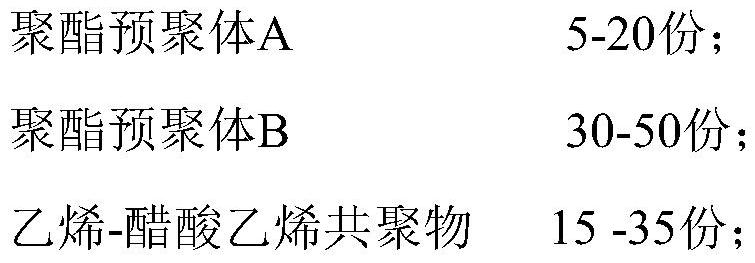

[0050] A kind of wormwood powder shoe material, comprises the raw material of following weight portion:

[0051]

[0052] In this embodiment, the preparation of the polyester prepolymer A includes the following steps: Weighing 1,4-butanediol and succinic acid with a molar ratio of 1.1:1 and mixing them uniformly, under normal pressure nitrogen protection conditions, After raising the temperature to 170°C and stirring for 1.5 hours, add catalyst A and antioxidant A, continue to raise the temperature to 210°C until almost no water is distilled, and then gradually reduce the pressure to below 5kPa for polycondensation reaction for 4 hours, then stop the reaction. That is, the polyester prepolymer A is obtained.

[0053] The preparation of the polyester prepolymer B comprises the steps of: weighing a short-chain dibasic alcohol and an aliphatic saturated dibasic acid with an alkyd molar ratio of 1.1:1 and mixing them uniformly; Stir and react at 160-180°C for 1.5h, add catalys...

Embodiment 3

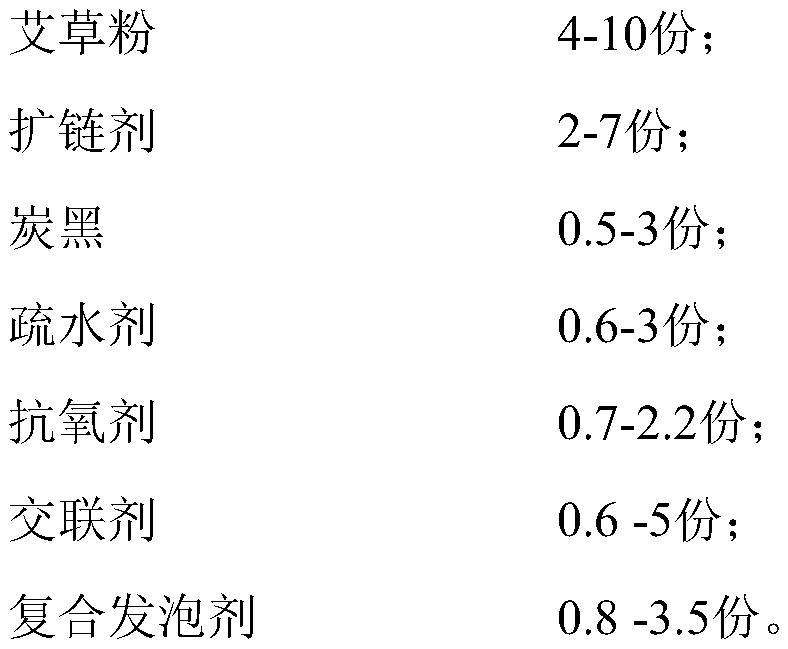

[0067] A kind of wormwood powder shoe material, comprises the raw material of following weight portion:

[0068]

[0069] In this embodiment, the preparation of the polyester prepolymer A includes the following steps: Weighing 1,4-butanediol and succinic acid with a molar ratio of 1.1:1 and mixing them uniformly, under normal pressure nitrogen protection conditions, Raise the temperature to 180°C and stir the reaction for 1 hour, add catalyst A and antioxidant A, continue to raise the temperature to 200-220°C until almost no water is distilled, then gradually reduce the pressure to below 5kPa for polycondensation reaction for 5 hours, then stop the reaction , Promptly make described polyester prepolymer A.

[0070] The preparation of the polyester prepolymer B comprises the steps of: weighing a short-chain dibasic alcohol and an aliphatic saturated dibasic acid with an alkyd molar ratio of 1.2:1 and mixing them uniformly; After stirring and reacting at 180°C for 1 hour, ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com