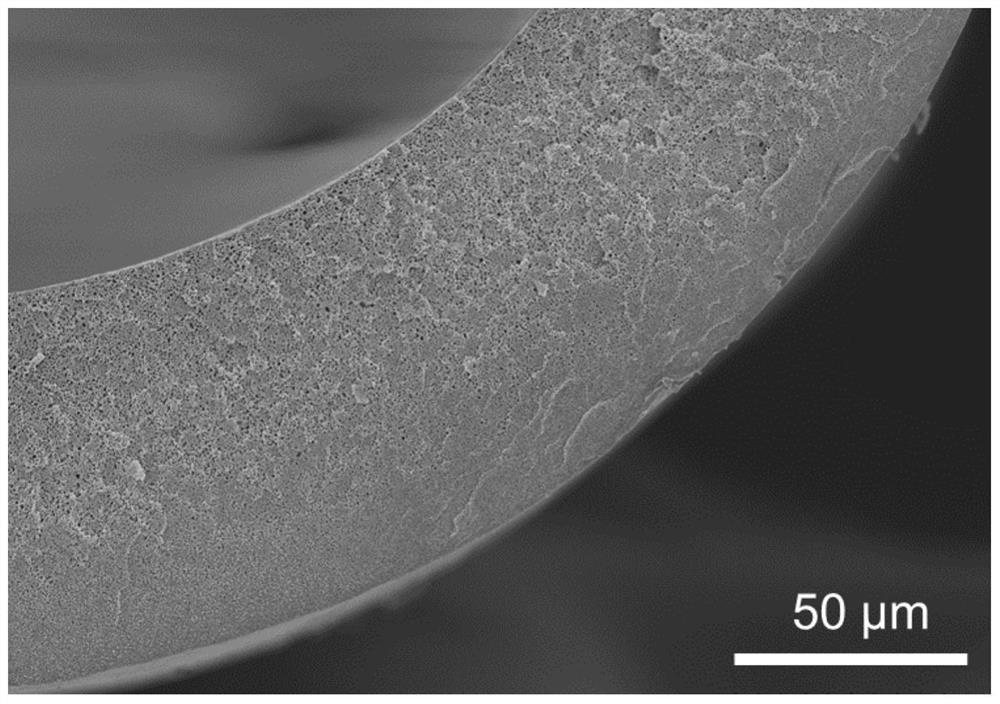

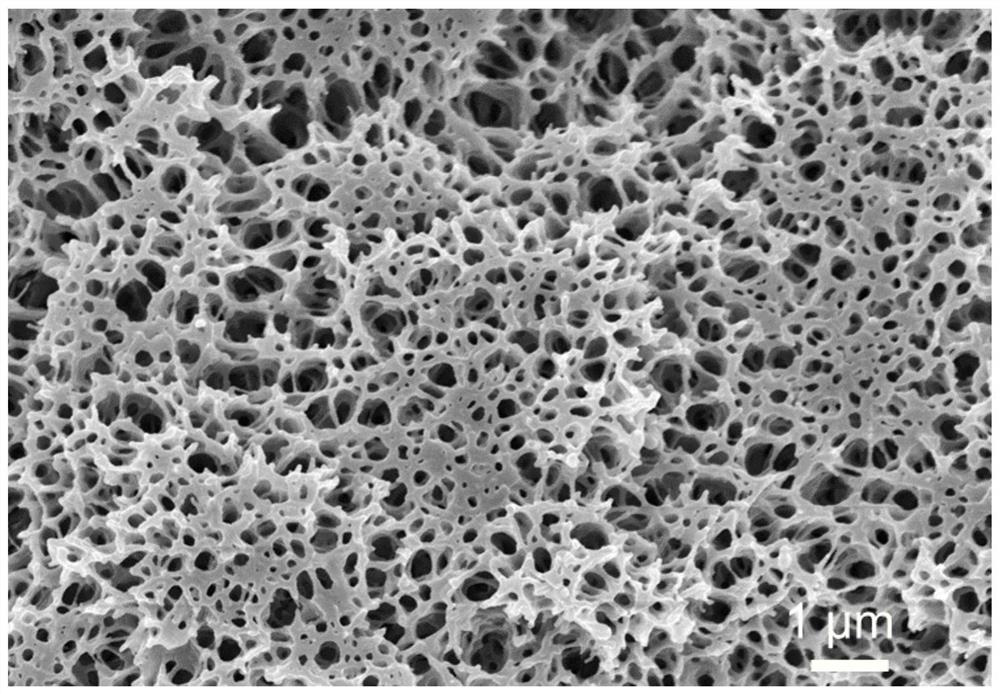

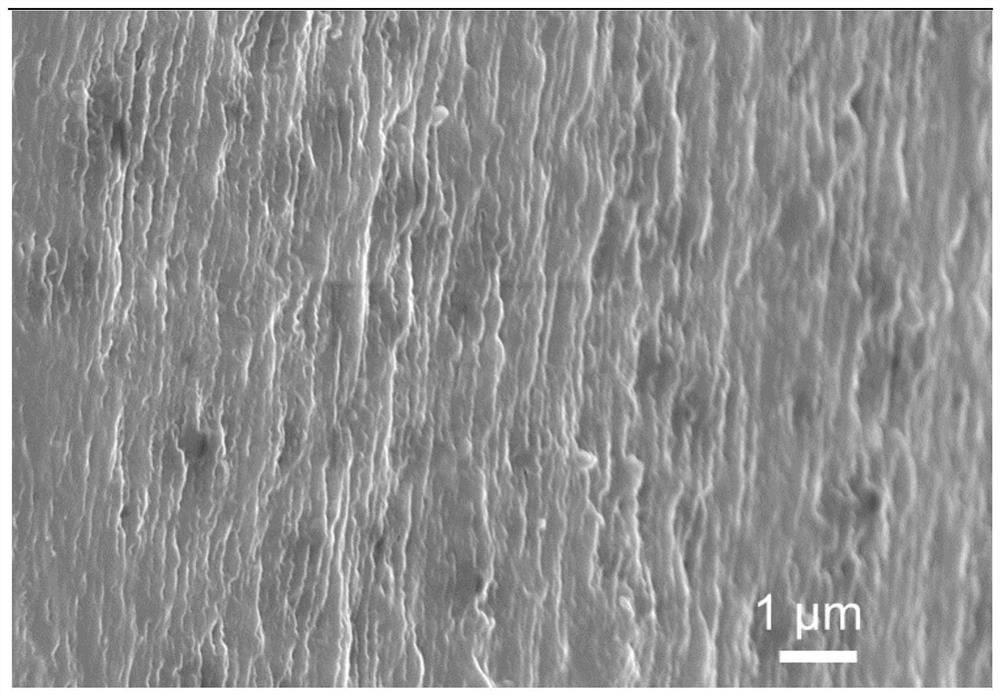

Poly(4-methyl-1-pentene) hollow fiber membrane and preparation method thereof

A fiber membrane and hollow technology, which is applied in the field of poly-4-methyl-1-pentene hollow fiber membrane and its preparation, can solve the problems of tight production capacity, limited production capacity of downstream ECMO enterprises, high prices, etc., and achieve the expansion of scope , environmental protection and product safety advantages, the effect of enhancing gas permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1) Preparation of casting solution: mixing poly-4-methyl-1-pentene resin with poor solvent linseed oil and good solvent hydrogenated vegetable oil at 25°C to obtain spinning slurry;

[0027] The mass fraction of controlling poly-4-methyl-1-pentene is 40%, and the diluent mass fraction is 60%;

[0028] In the diluent, the mass fraction of good solvent is 95%, and the mass fraction of poor solvent is 5%;

[0029] Adjust the component content in the casting solution as follows: the mass fraction of poly-4-methyl-1-pentene resin is 40%, the mass fraction of linseed oil is 3%, and the mass fraction of hydrogenated vegetable oil is 57%;

[0030] 2) Preparation of nascent hollow fibers: Add the casting solution to a twin-screw extruder and extrude at 230°C;

[0031] 3) Condensation and solidification: through the spinning nozzle of the screw extruder, the nascent hollow fiber passes through the air section with a height of 0.3cm, and then enters the condensate at a temperatur...

Embodiment 2

[0035] 1) Preparation of casting solution: mix poly-4-methyl-1-pentene resin with dibutyl sebacate, behenic acid, and glycerin at 100°C to obtain spinning slurry, in which poly-4-methyl The mass fraction of 1-pentene resin is 35%, the mass fraction of dibutyl sebacate is 30%, the mass fraction of behenic acid is 30%, and the mass fraction of glycerin is 5%;

[0036] 2) Preparation of nascent hollow fibers: Add the casting liquid to a twin-screw extruder, extrude at 220°C, and the height of the air section is 0.8cm;

[0037] 3) Condensation and solidification: through the spinning nozzle of the screw extruder, the nascent hollow fiber passes through the air section with a height of 0.8cm, and then enters the condensate at a temperature of -2°C to solidify and form a film; the condensate is ethylene glycol and water 1:1 mixture;

[0038] 4) Extraction and washing: After the condensate is solidified to form a film, it is immersed in an ethanol extraction solution at a temperatur...

Embodiment 3

[0040] Change the mass fraction of poly-4-methyl-1-pentene resin in Step 1) of Example 1 to 20%, change the extrusion temperature in Step 2) to 260°C, and keep other conditions unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com