Synthesis process of methoxypropylamine

A technology of methoxypropylamine and synthesis process, which is applied in the preparation of amino hydroxyl compounds, the preparation of organic compounds, organic chemistry, etc., can solve the problems of low conversion rate of reaction results, high operation difficulty, low selectivity, etc., and achieve the benefit of large Scale production control, good selectivity, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

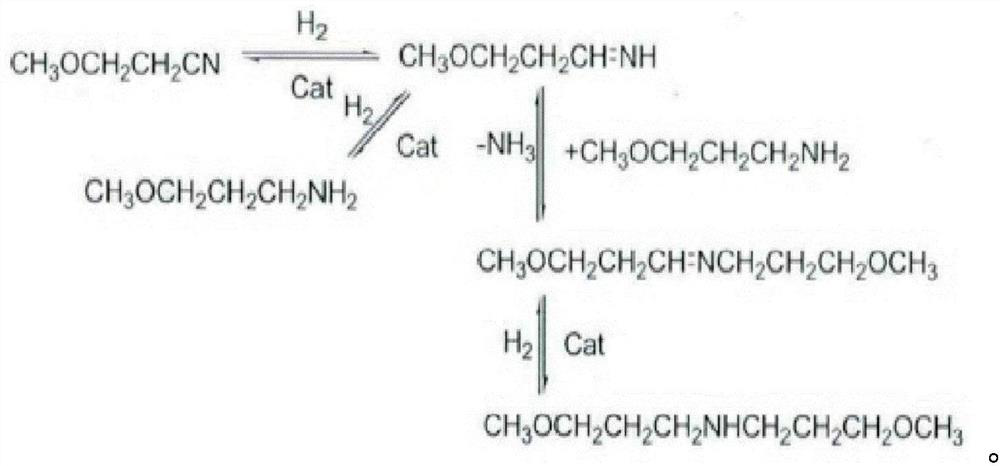

[0019] A kind of synthetic method of 3-methoxypropylamine, take 3-methoxypropionitrile as raw material catalytic hydrogenation:

[0020] Put 400g 3-methoxypropionitrile, 20g ethanol, 12g modified carrier nickel catalyst into a 1000ml autoclave; The pressure was stirred and reacted at 2.8MPa for 2h. After the reaction was completed, the reaction was cooled to room temperature, and then the still liquid was filtered and rectified under normal pressure (collecting fractions at 110-160°C) to obtain 354.09g of colorless and transparent 3-methoxypropylamine. The conversion rate of the raw material obtained after the reaction was analyzed by gas chromatography was 97.0%, and the product yield was 94.52%.

Embodiment example 2~ Embodiment example 6

[0022] The amount of the catalyst used in Example 1 is adjusted, and the rest of the conditions are the same as in Example 1. The conversion rate and total yield of raw materials are shown in the table below.

[0023] implementation 1 2 3 4 5 6 Catalyst addition amount / g 12 0.4 4 20 40 60 Raw material conversion rate / % 97 95.2 96.21 97.23 97.15 97.02 Product yield / % 94.52 92.11 91.68 95.43 95.11 95.86

Embodiment example 7~ Embodiment example 10

[0025] The temperature and pressure conditions in the implementation case 1 are adjusted, and the remaining conditions are equal to the implementation case 1, and the obtained raw material conversion rate and total yield are shown in the following table.

[0026] Implementation case serial number 1 7 8 9 10 temperature / ℃ 90 60 130 90 90 Pressure / MPa 2.80 2.80 2.80 2.00 3.00 Raw material conversion rate / % 97 95.56 97.73 95.11 97.13 Product yield / % 94.52 92.83 94.44 92.55 94.87

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com