Preparation method of alumina polishing powder

A technology of alumina polishing powder and aluminum hydroxide, applied in polishing compositions containing abrasives, etc., can solve the problems of reduced self-sharpening of alumina products, low polishing efficiency, slow polishing speed, etc. Improves hardness and prevents particle agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

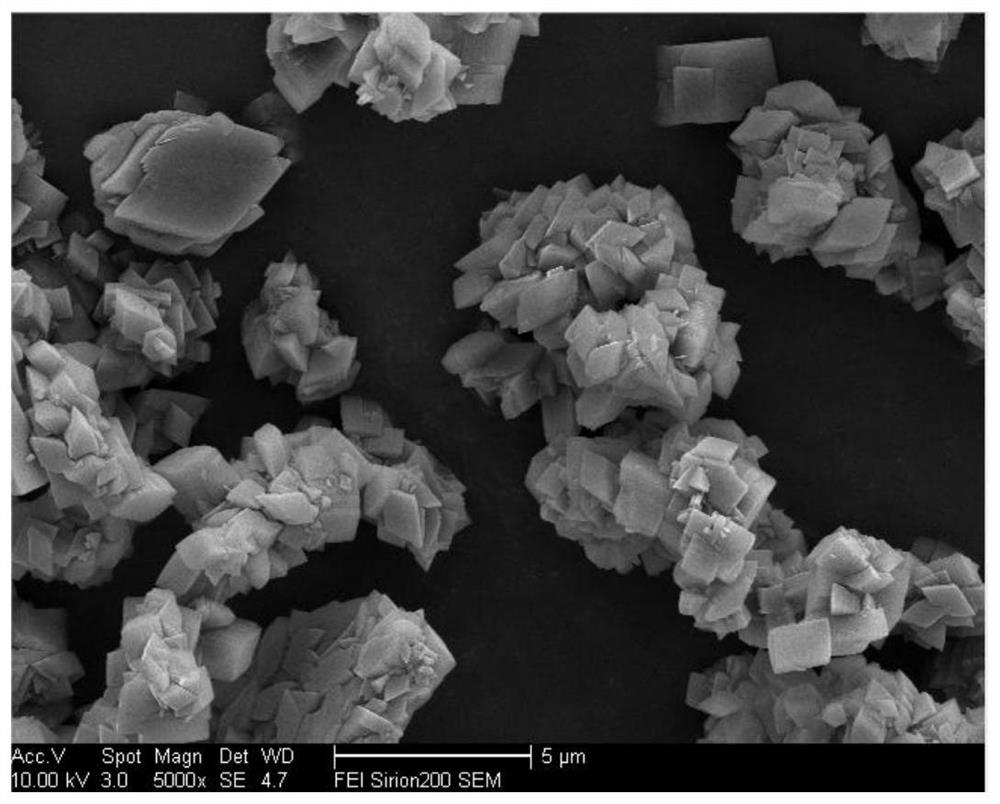

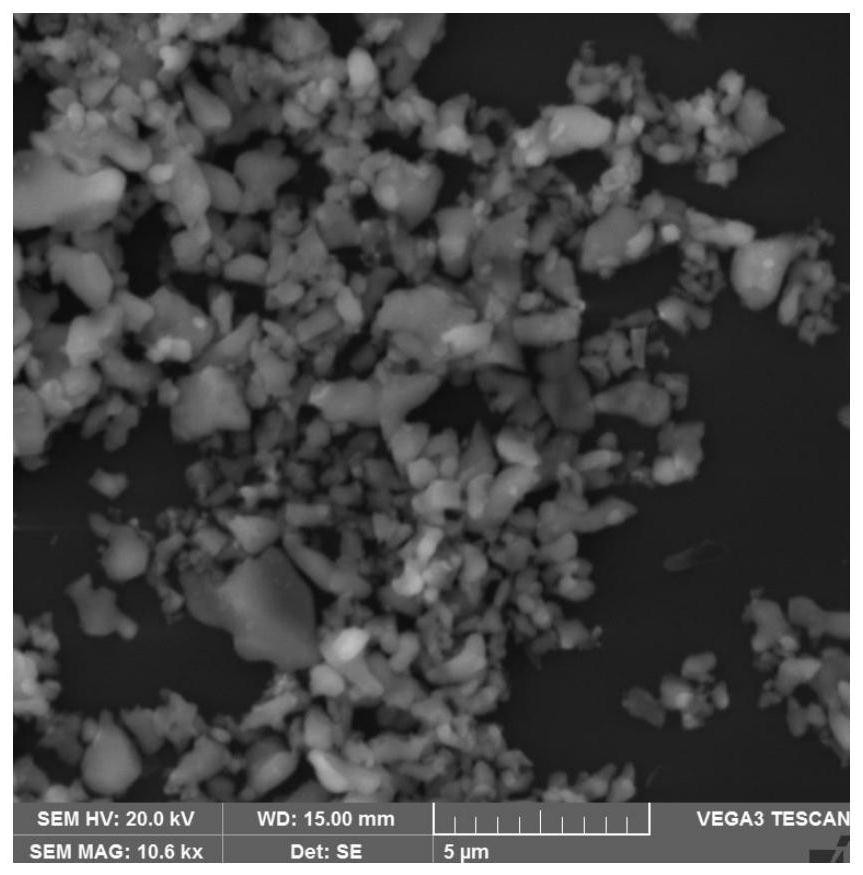

[0043] see figure 1 and figure 2 , the present invention provides a kind of technical scheme: a kind of preparation method of aluminum oxide polishing powder, comprises the following steps:

[0044] S1, prepare aluminum hydroxide:

[0045] S11. Settling and separating the diluted bauxite to obtain a crude liquid;

[0046] S111, adding the crushed bauxite into a grinder for grinding, adding caustic soda or lime for wet grinding during the grinding process, and dissolving the pulp;

[0047] S112. After the pulp is diluted, the diluted liquid is subjected to sedimentation and separation to obtain the upper thick liquid and the lower thick red mud slurry, and the upper thick liquid can be obtained;

[0048] S12, the crude liquid is filtered to obtain semen;

[0049] S13. Add aluminum hydroxide seed crystals to the semen to precipitate aluminum hydroxide, and wash the aluminum hydroxide. The particle size of aluminum hydroxide is required: D10: 30-35 μm, D50: 50-55 μm, D90: 65...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com