Compound piglet feed and production method thereof

A technology of piglet feed and production method, applied in the field of pig feed, can solve problems such as reducing the direct pressure of inner particles, and achieve the effect of reducing the direct pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

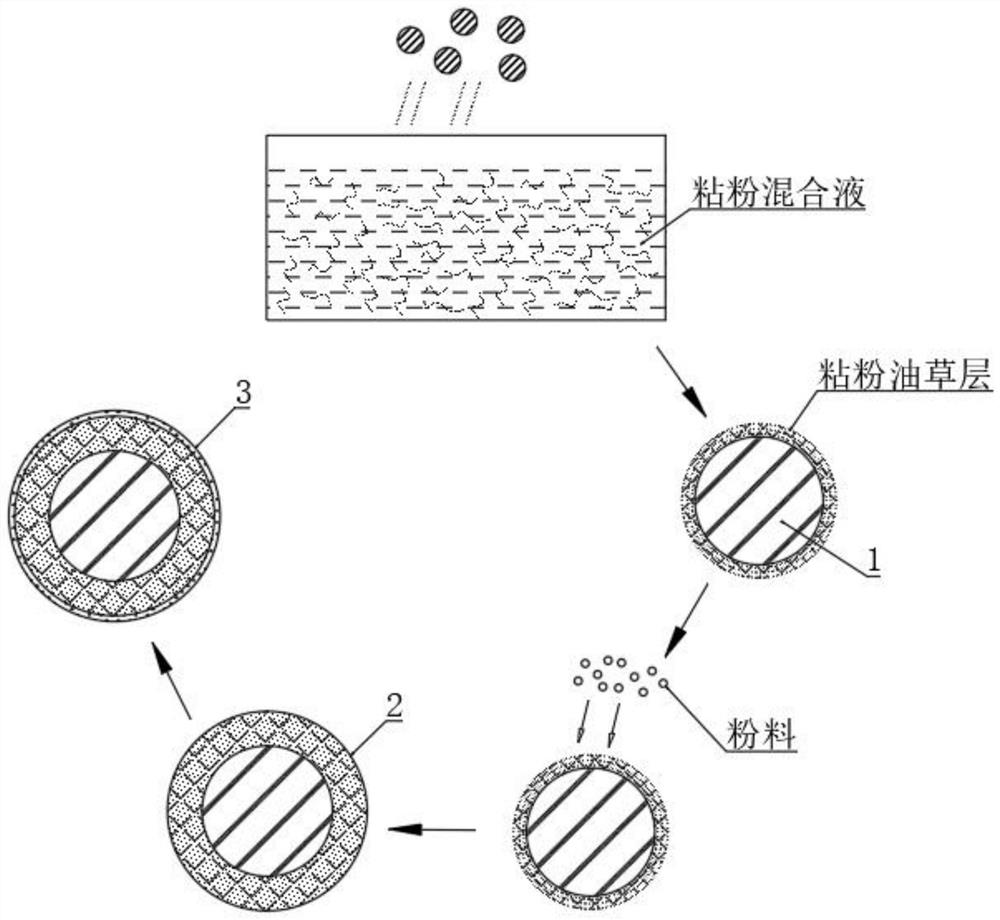

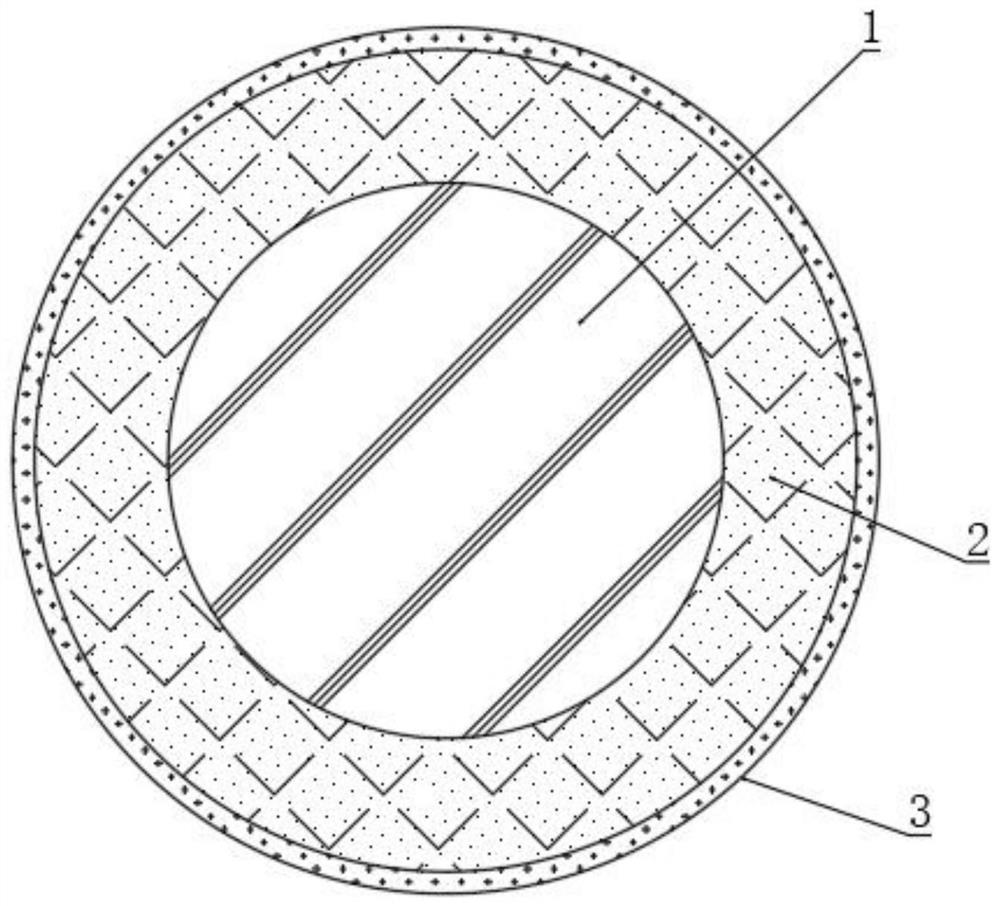

[0049] see figure 1, a compound feed for piglets, comprising an inner granule 1, a sandwich buffer layer 2 and an outer envelope 3, the sandwich buffer layer 2 includes powder, forage grass and oil, the forage grass includes emperor bamboo grass and rye grass, and the oil includes animal Fat and vegetable fat, the volume ratio of animal fat and vegetable fat is 1:1, the powder and inner particles 1 include the following raw materials: corn, wheat bran, soybean meal, fish meal, calcium carbonate, calcium hydrogen phosphate, salt, Vitamins, Lysine, Methionine.

[0050] A production method of compound feed for piglets, comprising the following steps:

[0051] S1. Milling: Fully pulverize and uniformly mix various raw materials to form powder;

[0052] S2. Granulation: Part of the powder is granulated to obtain the inner granule 1, and the remaining powder is used for another use;

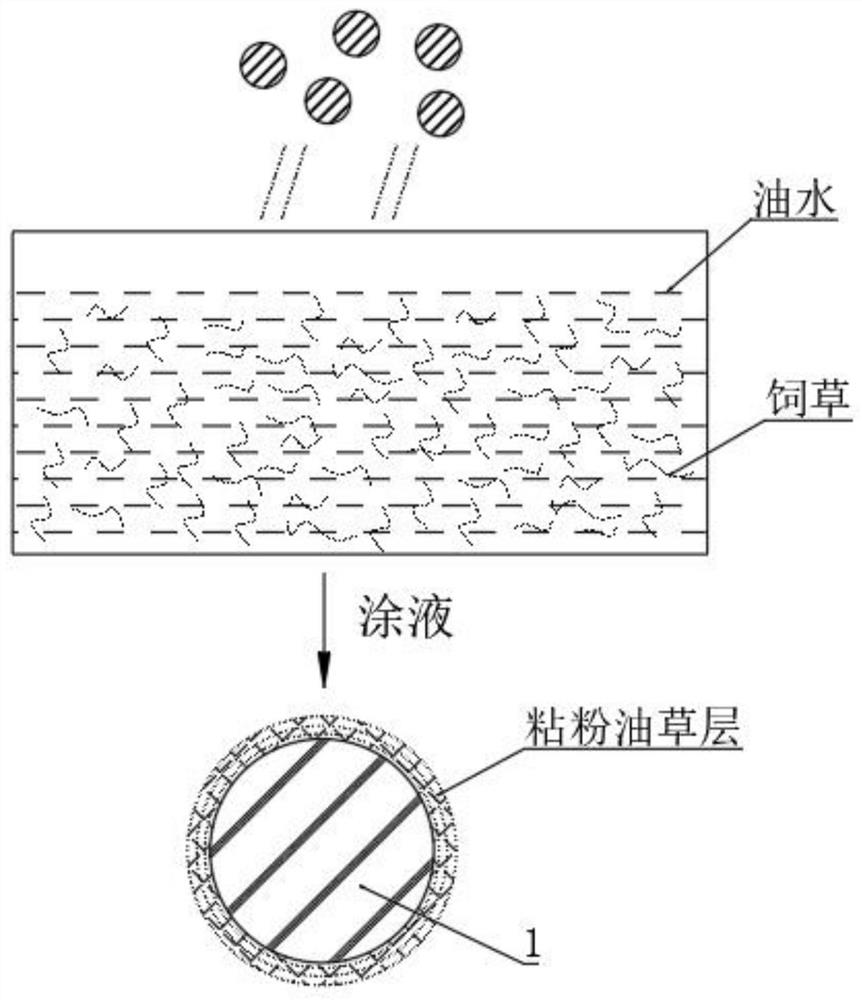

[0053] S3, configure mucus: prepare sticky powder mixture by forage grass, grease and deionized ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com