Preparation method of 2D/1D heterojunction photocatalyst and application of 2D/1D heterojunction photocatalyst in antibiosis

A photocatalyst and heterojunction technology, applied in the field of photocatalytic materials, to achieve the effects of improved antibacterial performance, low cost, and strong visible light absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

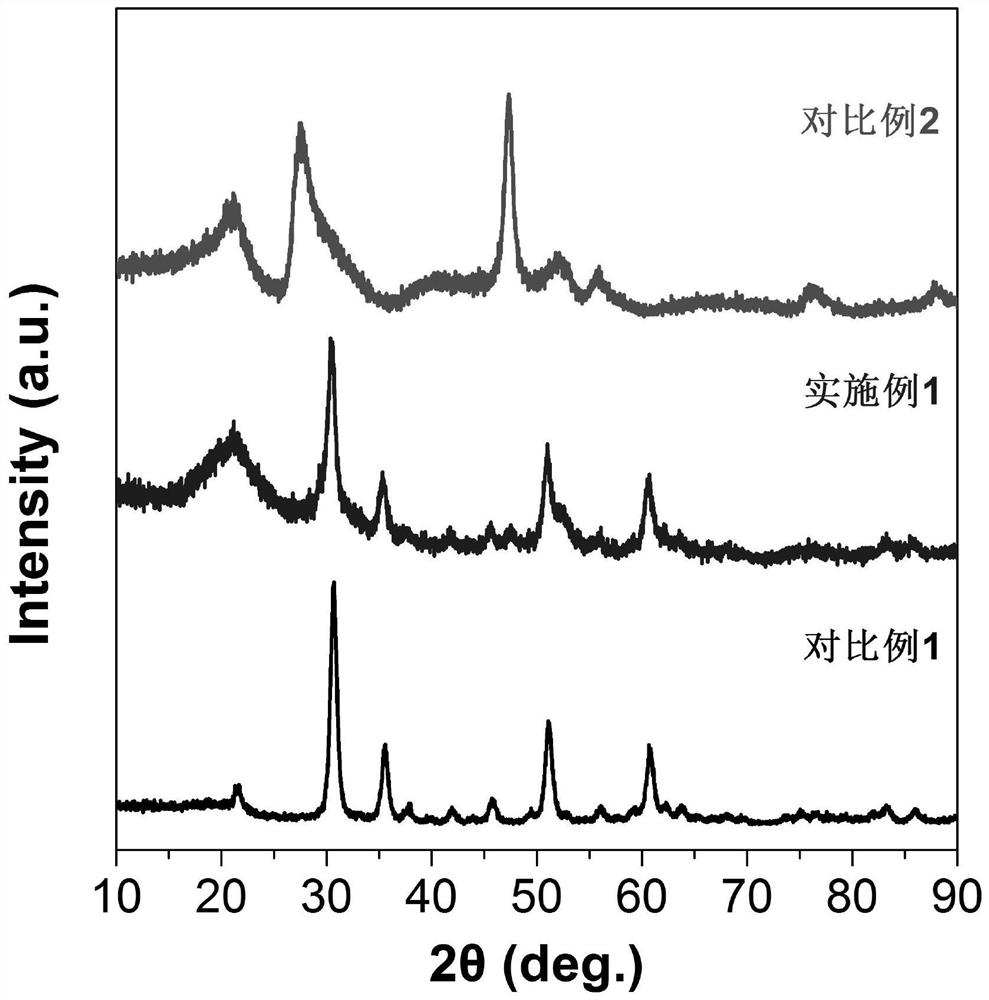

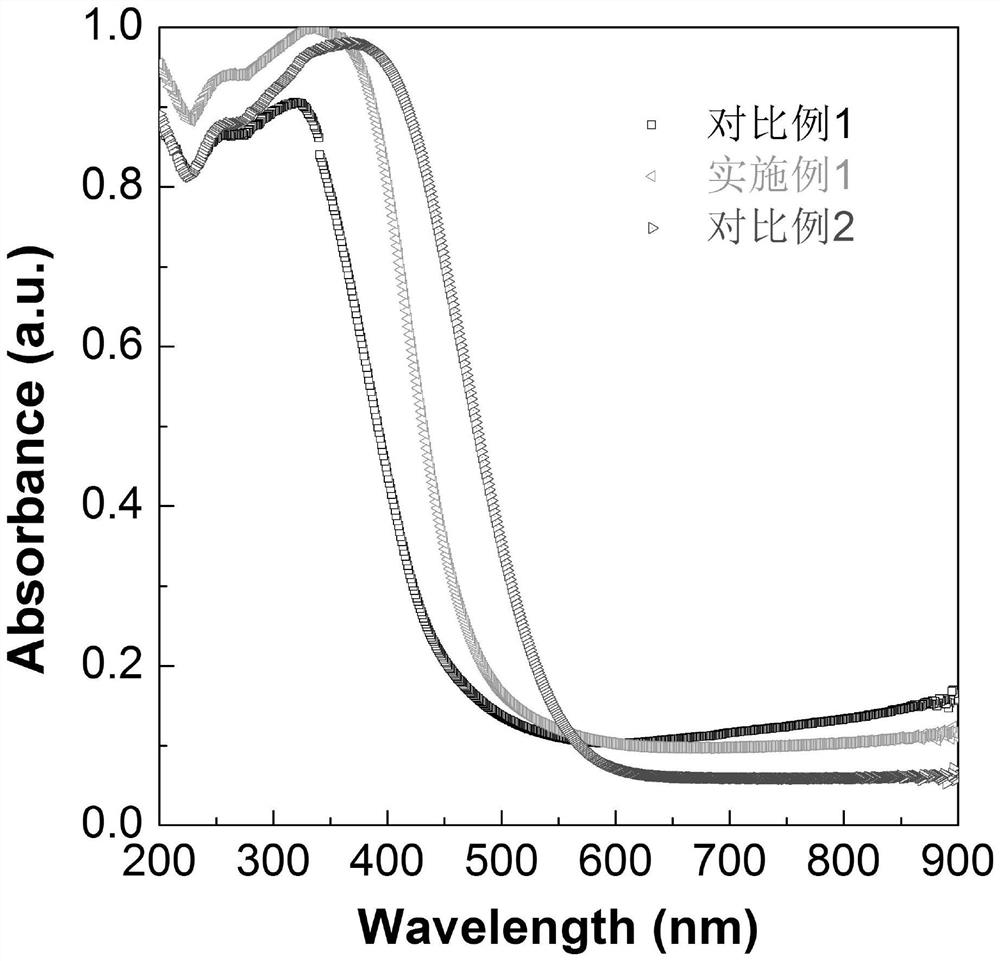

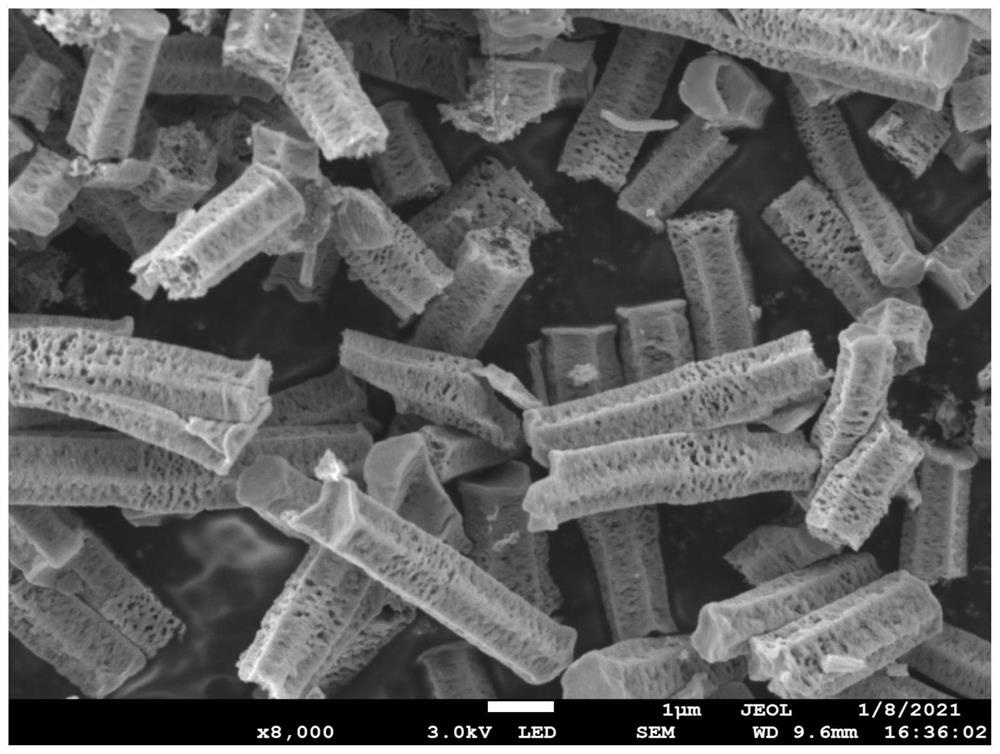

Embodiment 1

[0036] Dissolve 180 mg of indium nitrate and 150 mg of terephthalic acid in 150 ml of N,N-dimethylformamide, transfer to an oil bath at 110°C for 50 minutes, heat and stir for 50 minutes, wash with centrifuge and dry before transferring Heating in a low-temperature muffle furnace at 150°C for 1.5 hours with a heating rate of 4°C / min, and then transferred to a high-temperature muffle furnace at 450°C for 3 hours at the same heating rate to obtain porous In 2 o 3 nanotube. Take 30 mg of the above Porous Ind 2 o 3 The nanotubes were dispersed in 50 ml of deionized water, and the ZnIn 2 S 4 The precursors (108.9 mg of zinc chloride, 176.9 mg of indium chloride and 240.4 mg of thioacetamide) were sequentially added to the above dispersion, mixed evenly, heated and stirred in an oil bath at 70°C for 3 hours, and then washed by centrifugation , you can get 2D ultra-thin ZnIn 2 S 4 Nanosheet / 1D Porous In 2 o 3 Nanotube heterojunction.

Embodiment 2

[0038] Dissolve 180 mg of indium nitrate and 150 mg of terephthalic acid in 150 ml of N,N-dimethylformamide, transfer to a 100°C oil bath, heat and stir for 60 minutes, centrifuge, wash and dry, then transfer Heating in a low-temperature muffle furnace at 130°C for 2.5 hours with a heating rate of 5°C / min, and then transferred to a high-temperature muffle furnace at 550°C for 2 hours at the same heating rate to obtain porous In 2 o 3 nanotube. Take 30 mg of the above Porous Ind 2 o 3 The nanotubes were dispersed in 50 ml of deionized water, and the ZnIn 2 S 4 The precursors (81.6 mg of zinc chloride, 176.9 mg of indium chloride and 180.3 mg of thioacetamide) were sequentially added to the above dispersion, mixed evenly, heated and stirred in an oil bath at 90°C for 1.5 hours, and then washed by centrifugation , you can get 2D ultra-thin ZnIn 2 S 4 Nanosheet / 1D Porous In 2 o 3 Nanotube heterojunction.

Embodiment 3

[0040] Dissolve 180 mg of indium nitrate and 150 mg of terephthalic acid in 150 ml of N,N-dimethylformamide, transfer to a 140°C oil bath, heat and stir for 30 minutes, centrifuge, wash and dry, then transfer Heating in a low-temperature muffle furnace at 100°C for 3 hours with a heating rate of 6°C / min, and then transferred to a high-temperature muffle furnace at 500°C for 2.5 hours at the same heating rate to obtain porous In 2 o 3 nanotube. Take 30 mg of the above Porous Ind 2 o 3 The nanotubes were dispersed in 50 ml of deionized water, and the ZnIn 2 S 4 Precursors (146.7 mg of zinc acetate, 176.9 mg of indium chloride and 150.2 mg of thioacetamide) were sequentially added to the above dispersion, mixed evenly, heated and stirred in an oil bath at 80°C for 2.5 hours, and then washed by centrifugation and water. You can get 2D ultra-thin ZnIn 2 S 4 Nanosheet / 1D Porous In 2 o 3 Nanotube heterojunction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com