Special compound microbial fertilizer for alfalfa in saline-alkali soil and preparation method thereof

A technology of compound microbial bacteria and saline-alkali land, applied in the direction of soil preparation, microbial treatment, fertilizer made from biological waste, etc., can solve the problems of low yield of alfalfa and insufficient soil nutrients for alfalfa, so as to promote the growth of alfalfa and improve soil water holding capacity ability, the effect of reducing the amount of nitrogen fertilizer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

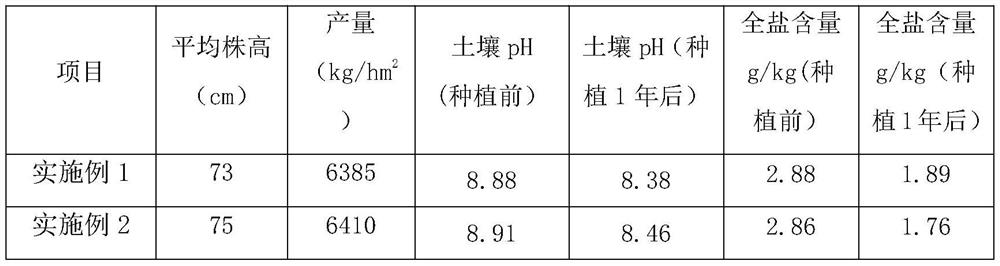

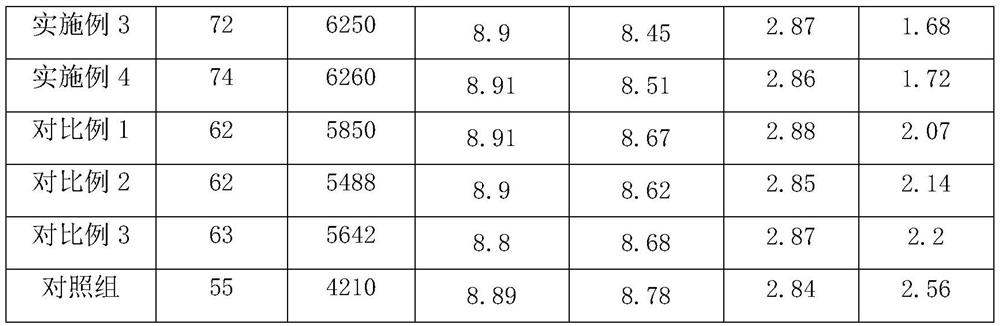

Examples

Embodiment 1

[0043] In terms of parts by mass, the raw materials are:

[0044] 10 parts of saline-alkali tolerant, phosphorus- and potassium-decomposing rhizobia compound bacterial agent, 30 parts of soybean straw, 22 parts of caragana branches, 24 parts of furfural residue, 9 parts of desulfurized gypsum, 11 parts of superphosphate, and 7.5 parts of fulvic acid.

[0045] Preparation:

[0046] Weigh the raw materials according to the above-mentioned parts by mass, crush the soybean stalks, caragana branches and furfural slag to a particle size of 100 mesh, dry them, add fermentation and decomposing bacteria agents and adjust the water, then add desulfurized gypsum, and carry out aerobic solid-state fermentation , the fermentation temperature reaches 65°C, and the fermentation time is 20 days. From the beginning of fermentation to when the temperature of the fermented material reaches 65°C, turn over the material, repeat 4 times until the end of fermentation; then add fulvic acid, superphos...

Embodiment 2

[0048] In terms of parts by mass, the raw materials are:

[0049] 3 parts of saline-alkali tolerant, phosphorus- and potassium-dissolving rhizobia compound bacterial agent, 32 parts of wheat straw, 18 parts of wolfberry branches, 22 parts of furfural residue, 8 parts of desulfurized gypsum, 7 parts of superphosphate, and 10 parts of fulvic acid.

[0050] Preparation:

[0051] Weigh the raw materials according to the above-mentioned parts by mass, crush wheat straw, wolfberry branches and furfural slag to a particle size of 80 mesh, dry, add fermentation and decomposing bacteria agent and adjust the water, then add desulfurized gypsum, and carry out aerobic solid-state fermentation. The fermentation temperature is 65°C, and the fermentation time is 15 days. From the beginning of fermentation to when the temperature of the fermented material reaches 65°C, turn over the material, repeat 3 times until the end of fermentation; then add fulvic acid, superphosphate and salt-alkali-re...

Embodiment 3

[0053] In terms of parts by mass, the raw materials are:

[0054] Salt-alkali-tolerant, phosphorus- and potassium-soluble rhizobia compound bacterial agent 15%, corn stalks 16%, peanut vines 12%, grape branches 26%, furfural slag 26%, desulfurized gypsum 10%, superphosphate 15 parts, fulvic acid 5%.

[0055] Preparation:

[0056] Weigh the raw materials according to the above-mentioned parts by mass, crush corn stalks, peanut vines, grape branches and furfural slag to a particle size of 120 mesh, dry them, add fermentation and decomposing bacteria agents and adjust the water, and then add desulfurized gypsum to carry out aerobic solid state After fermentation, the fermentation temperature is 60°C, and the fermentation time is 25 days. From the beginning of fermentation to when the temperature of the fermented material reaches 60°C, turn over the material, repeat 5 times until the end of fermentation; then add fulvic acid, superphosphate and salt-tolerant The compound bacteri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com