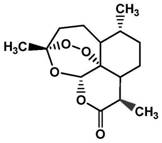

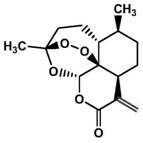

Method for selectively extracting and separating artemisinin/artemisitene by using hydrophilic ionic liquid

An ionic liquid, artemisinin technology, applied in organic chemistry and other directions, can solve the problems of long time and complicated operation, and achieve the effect of simple operation and reduced dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1) Mix an equal volume of 5% allyltrimethylammonium chloride aqueous solution (mole fraction) with a cyclohexane solution containing artemisinin / artemisinin (artemisinin content 4.9%), shake at 50°C for 5h , Stand at 50°C for 4h, and separate the layers to obtain a two-phase solution.

[0024] 2) Take 0.5 mL each of the extract phase (ionic liquid phase) and the raffinate phase (organic solvent phase) with a syringe, dilute to 5 mL with methanol, and determine artemisinin and artemisinin in the two phases by high performance liquid chromatography. concentration, the calculated separation selectivity is 6.45.

Embodiment 2

[0026] 1) Mix equal volumes of 5% triethylamine hydrochloride aqueous solution (mole fraction) and cyclohexane solution containing artemisinin / artemisinin (artemisinin content 4.9%), shake at 50°C for 5h, and 50°C After standing for 4h, the layers were separated to obtain a two-phase solution.

[0027] 2) Take 0.5 mL each of the extract phase (ionic liquid phase) and the raffinate phase (organic solvent phase) with a syringe, dilute to 5 mL with methanol, and determine artemisinin and artemisinin in the two phases by high performance liquid chromatography. concentration, the calculated separation selectivity was 5.97.

Embodiment 3

[0029] 1) Mix equal volumes of 5% allyltrimethylammonium chloride aqueous solution (mole fraction) with cyclohexane solution containing artemisinin / artemisinin (artemisinin content 5%), shake at 50°C for 0.5 h, stand at 50°C for 4h, and separate the layers to obtain a two-phase solution.

[0030] 2) Take 0.5 mL each of the extract phase (ionic liquid phase) and the raffinate phase (organic solvent phase) with a syringe, dilute to 5 mL with methanol, and determine artemisinin and artemisinin in the two phases by high performance liquid chromatography. concentration, the calculated separation selectivity was 4.67.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com