Photo-thermal ionic gel film as well as preparation method and application thereof

An ionogel and thin film technology, applied in the field of photothermal ionogel thin film and its preparation, can solve problems such as difficult solution processing, complex preparation of inorganic materials, and limited application in the field of flexible electronics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

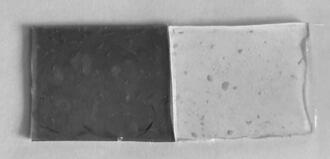

Embodiment 1

[0042] Take 10mL of butyl acrylate, 25μL of polyethylene glycol diacrylate, 1.4g of lithium bistrifluoromethanesulfonimide, and 0.14g of 1-hydroxycyclohexyl phenyl ketone, and prepare a set of the same ratio at the same time. However, 10 mg of the precursor solution of the light-to-heat conversion material MXene was added, and the mixture was dispersed uniformly by ultrasonication for 15 minutes.

[0043] The PTFE mold presents a "concave" shape as a whole, and a release film is pasted on the bottom of the PTFE mold. At the same time, paste a diaphragm in the middle of the release film, bend the diaphragm into an "L" shape, the height of the diaphragm is greater than the height of the PTFE mold, and the diaphragm divides the groove of the PTFE mold into two parts. The bottom of the diaphragm is coated with a thin layer of silicone oil so that the "L"-shaped diaphragm is attached to the middle part of the release film.

[0044] First take the precursor solution without adding ...

Embodiment 2

[0046] Take 8 mL of ethoxyethoxyethyl acrylate, 2 mL of hydroxybutyl acrylate, 50 μL of ethoxylated trimethylolpropane triacrylate, 1.45 g of lithium bistrifluoromethanesulfonylimide, 0.1 g 1-hydroxycyclohexyl phenyl ketone, at the same time prepare a set of solutions with the same ratio, add 10 mg ferric oxide nanoparticles, and ultrasonically disperse for 20 minutes to ensure uniform dispersion.

[0047] The PTFE mold presents a "concave" shape as a whole, and a release film is pasted on the bottom of the PTFE mold. At the same time, paste a diaphragm in the middle of the release film, bend the diaphragm into an "L" shape, the height of the diaphragm is greater than the height of the PTFE mold, and the diaphragm divides the groove of the PTFE mold into two parts. The bottom of the diaphragm is coated with a thin layer of silicone oil so that the "L"-shaped diaphragm is attached to the middle part of the release film.

[0048] Use a pipette gun to draw 1mL of precursor solut...

Embodiment 3

[0050] Take 9 mL of butyl acrylate, 1 mL of hydroxypropyl acrylate, 20 μL of polyethylene glycol diacrylate, 1 g of 1-ethyl-3-methylimidazole bistrifluoromethanesulfonimide salt, 0.1 g of 1 -Hydroxycyclohexyl phenyl ketone, at the same time, prepare a set of solutions with the same ratio, add 50 μL of black ink, and disperse evenly by ultrasonication for 15 minutes.

[0051] The PTFE mold presents a "concave" shape as a whole, and a release film is pasted on the bottom of the PTFE mold. At the same time, paste a diaphragm in the middle of the release film, bend the diaphragm into an "L" shape, the height of the diaphragm is greater than the height of the PTFE mold, and the diaphragm divides the groove of the PTFE mold into two parts. The bottom of the diaphragm is coated with a thin layer of silicone oil so that the "L"-shaped diaphragm is attached to the middle part of the release film.

[0052] Take 1mL of the precursor solution without black ink and irradiate it with 15 wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com