Cell micro-injection device and robust impedance control method thereof

A microinjection and impedance control technology, applied in the fields of biomedical engineering and precision control, can solve the problems of mechanism fatigue failure, unstable steady-state error, inability to compliant mechanism to achieve stiffness ratio, etc., to improve the success rate and reduce assembly. Error, avoid the effect of system instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

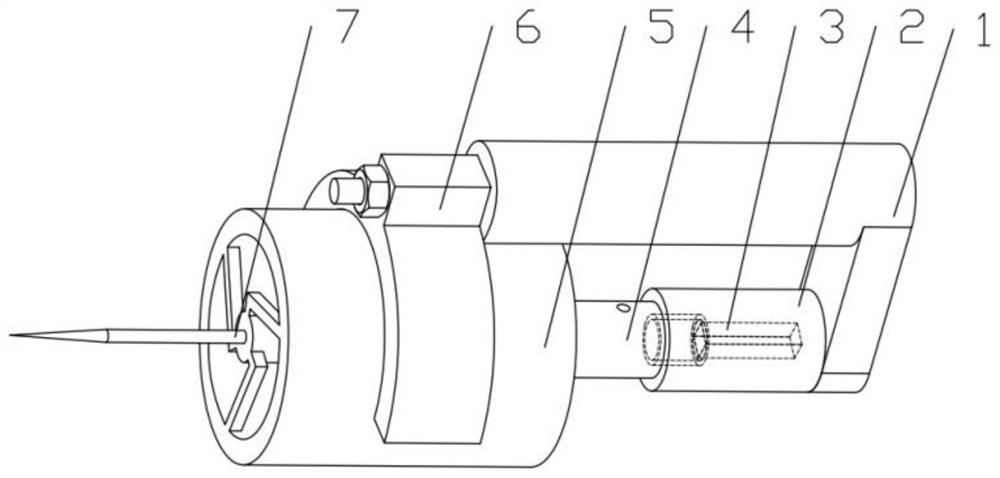

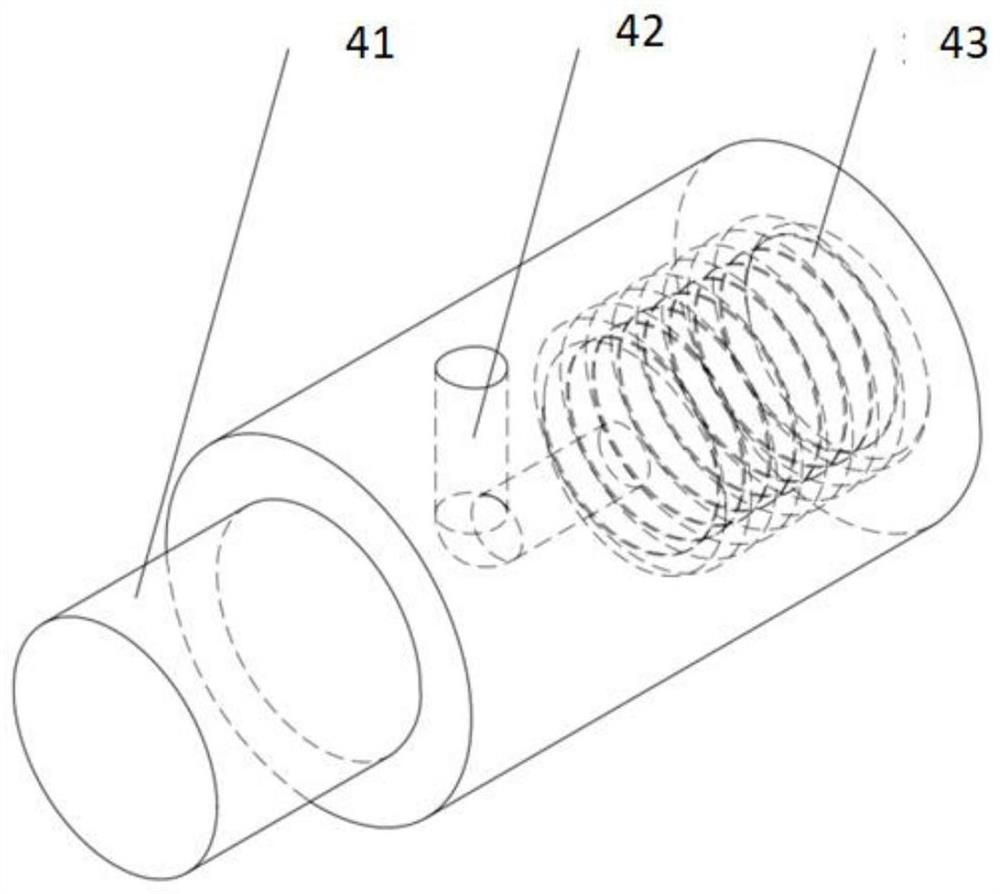

[0034] Such as Figure 1 to Figure 4 As shown, the cell microinjection device of the present invention includes a connecting rod 1 , a packager 2 , a piezoelectric driver 3 , an injector 4 , a hub type compliance mechanism 5 , a fixed chuck 6 , and a microinjection needle 7 .

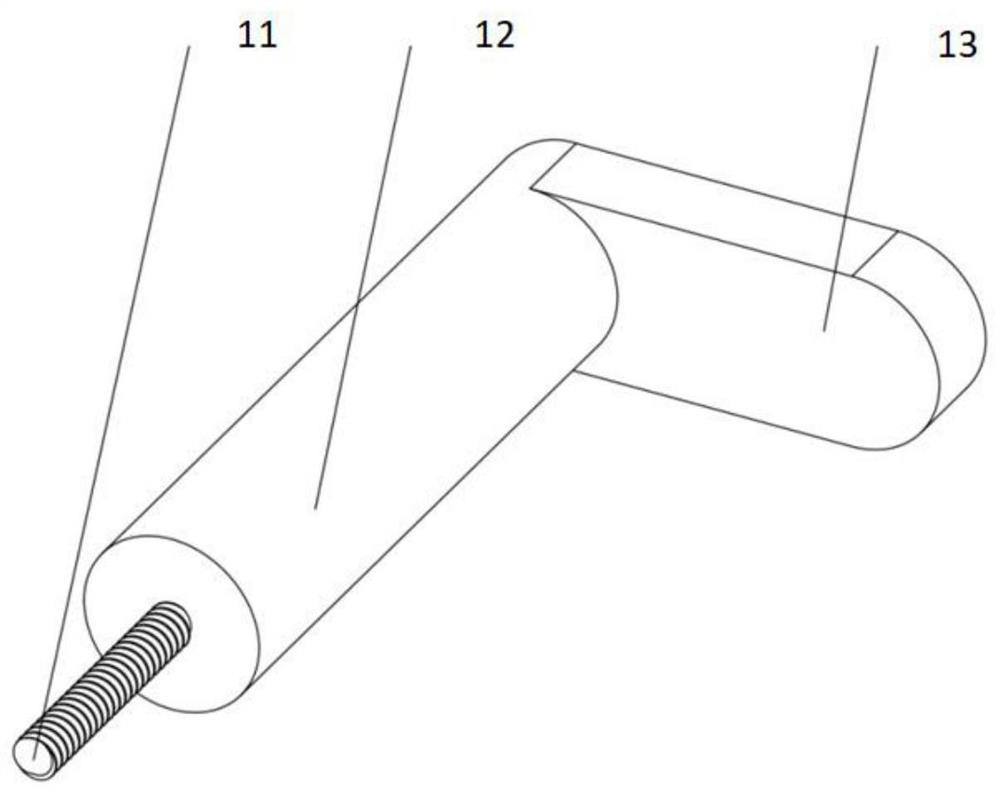

[0035] The connecting rod 1 includes a threaded part 11, a connecting part 12, and a pressing part 13, wherein the threaded part 11 is connected with the fixed collet 6, and the fixed collet 6 is fixed on the outside of the hub type compliance mechanism 5, and a threaded part 11 is also provided with a Nut, by rotating the nut to adjust the relative position of the connecting rod 1 and the fixed chuck 6; the pressing part 13 is against one end of the packager 2, and when the nut is tightened, the piezoelectric driver 3 in the packager 2 will be generated The effect of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com