High-entropy alloy fiber as well as preparation method and application thereof

A high-entropy alloy and fiber technology, used in non-precious metal oxide coatings, electrode coatings, electrolytic components, etc., can solve the problems of low platinum reserves and high platinum catalyst prices, and achieve uniform performance, good catalytic effect, and good stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

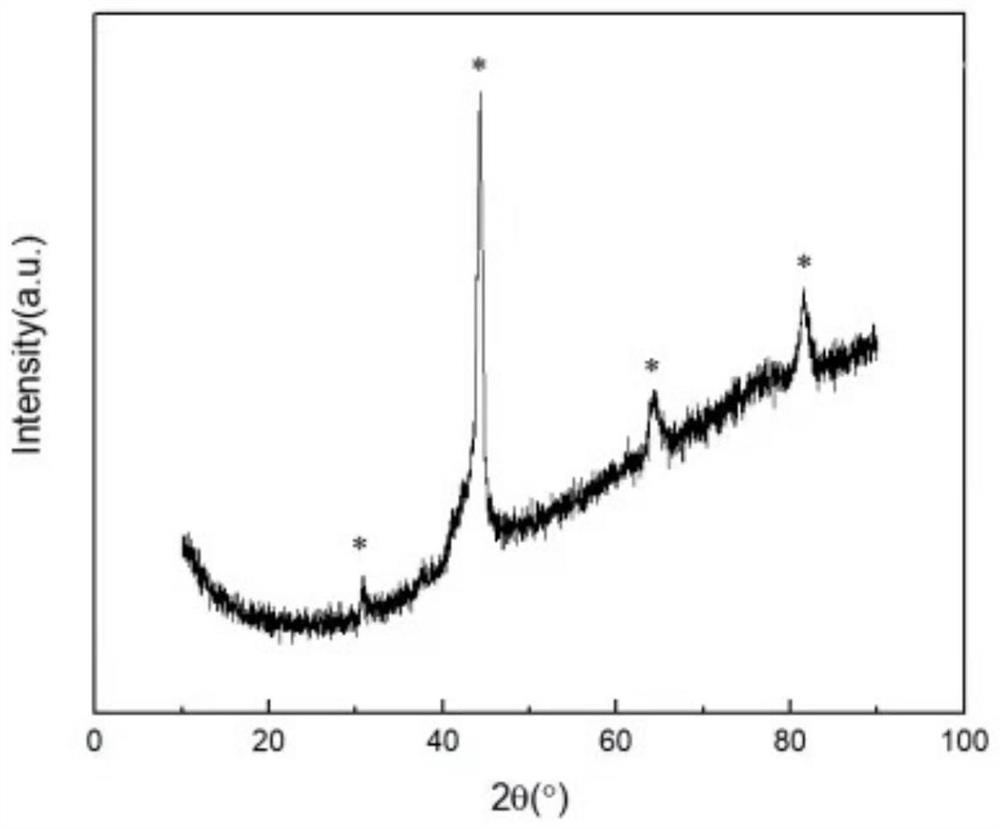

[0028] Embodiment 1: The preparation method of the high-entropy alloy fiber in this embodiment is realized according to the following steps:

[0029] 1. According to Fe 20 co 20 Ni 20 Mo 20 Al 20 The atomic percent, (after calculation) takes by weighing metal Fe, Co, Ni, Mo and Al, obtains mixed metal raw material;

[0030] 2. Use a high vacuum arc melting furnace to melt mixed metal raw materials into metal button ingots, and then melt and absorb the button ingots into master alloy rods with a diameter of 5-20mm;

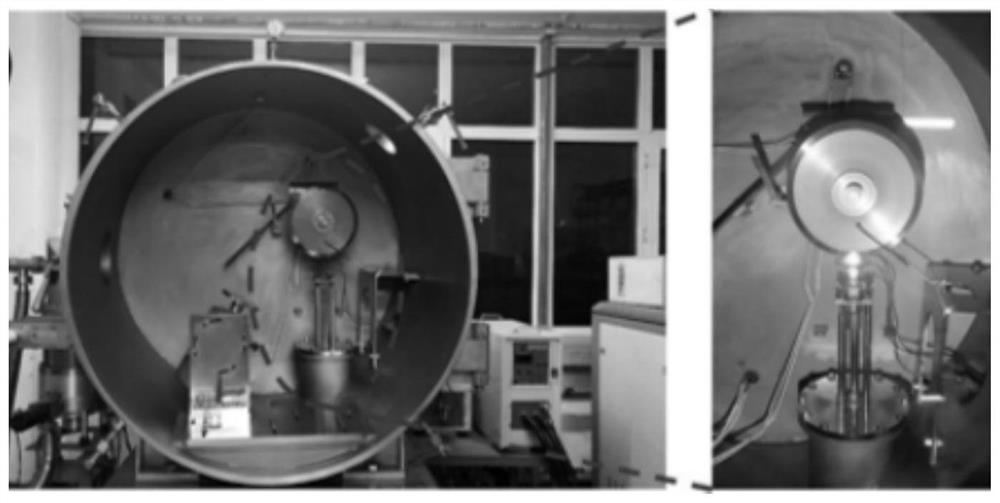

[0031] 3. Using melt drawing equipment to draw the master alloy rod to obtain alloy fibers;

[0032] 4. Put the alloy fiber into hydrochloric acid or NaOH solution for free dealloying to obtain the high-entropy alloy fiber.

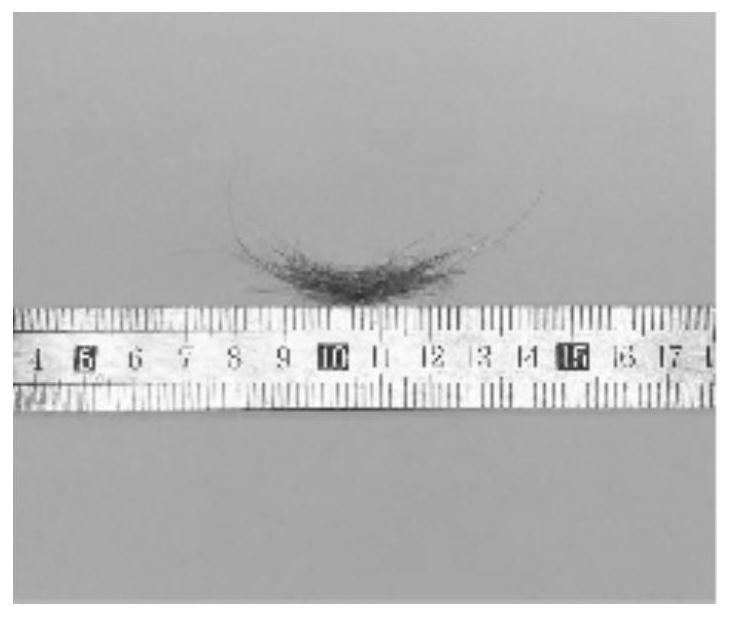

[0033] The composition of the high-entropy alloy fiber in this embodiment is Fe 20 co 20 Ni 20 Mo 20 Al 20 , with a diameter of about 20-38 μm. First, a rod with a diameter of 10 mm and a length of about 10 cm was obtained by Cu die...

specific Embodiment approach 2

[0034] Embodiment 2: This embodiment differs from Embodiment 1 in that the length of the master alloy rod in step 2 is 6-15 cm.

specific Embodiment approach 3

[0035] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that in step three, a mechanical pump and a molecular pump are used to evacuate the melt drawing equipment, and the vacuum degree is 10 -5 Pa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com