Bismuth-bismuthyl carbonate composite photocatalyst as well as preparation method and application thereof

A technology of bismuth oxycarbonate and composite light, which is applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the problems of high cost of precious metals and complicated processes, and achieve Short reaction time, cheap and easy-to-obtain raw materials, and high-efficiency degradation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

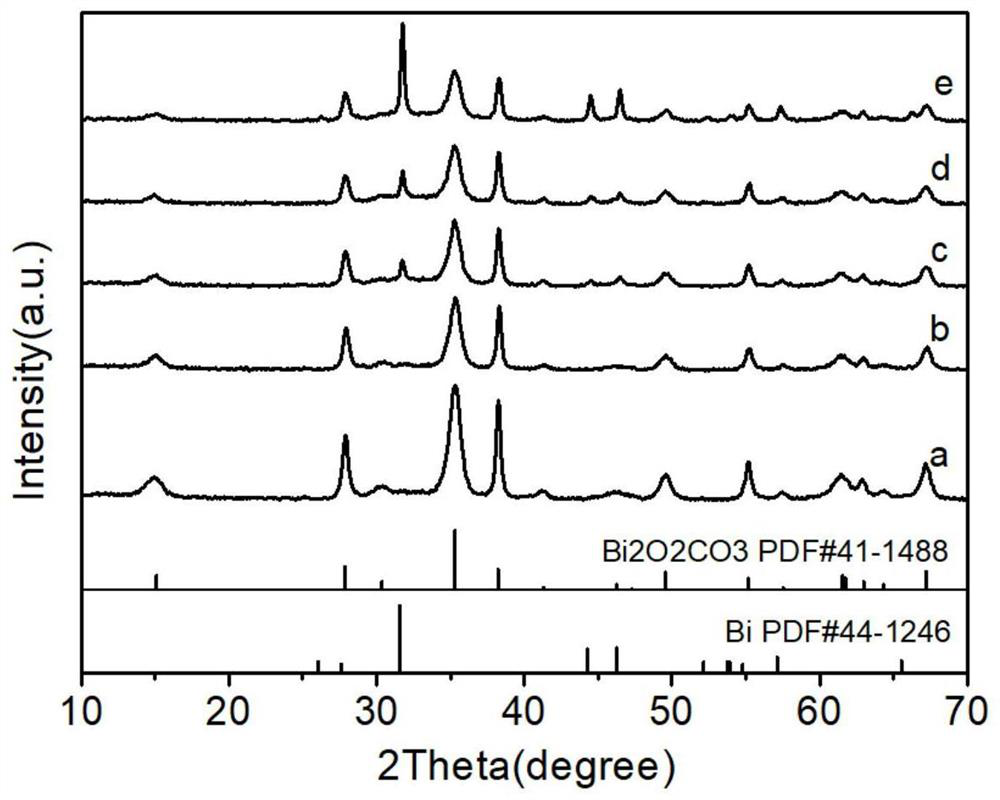

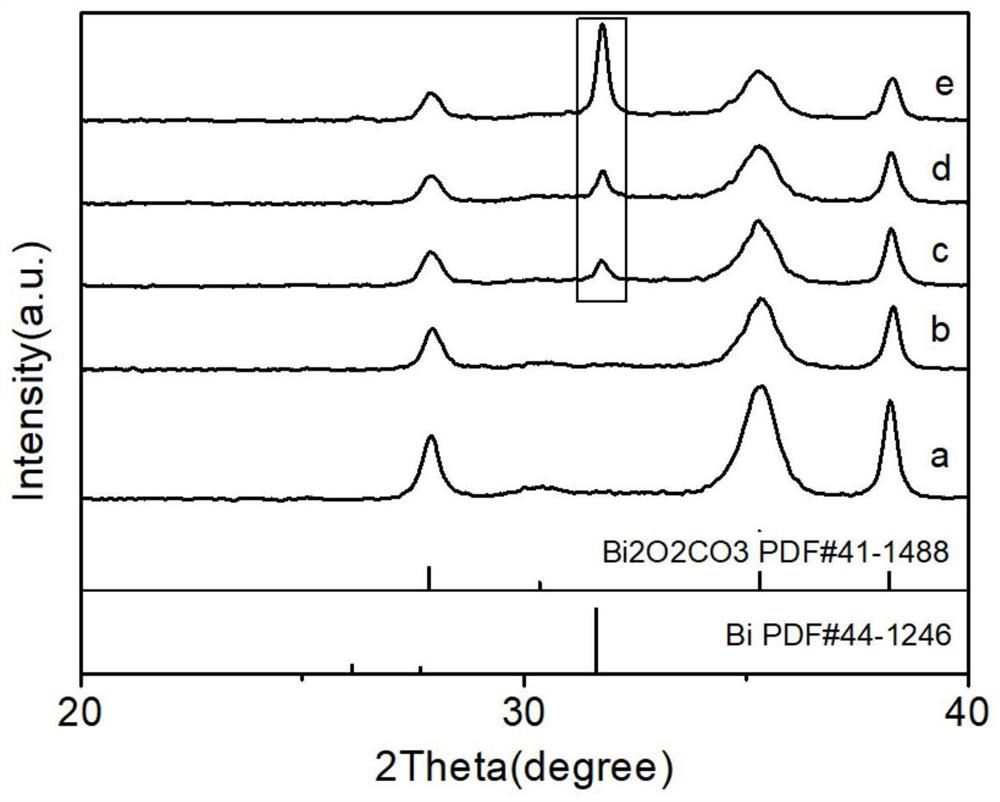

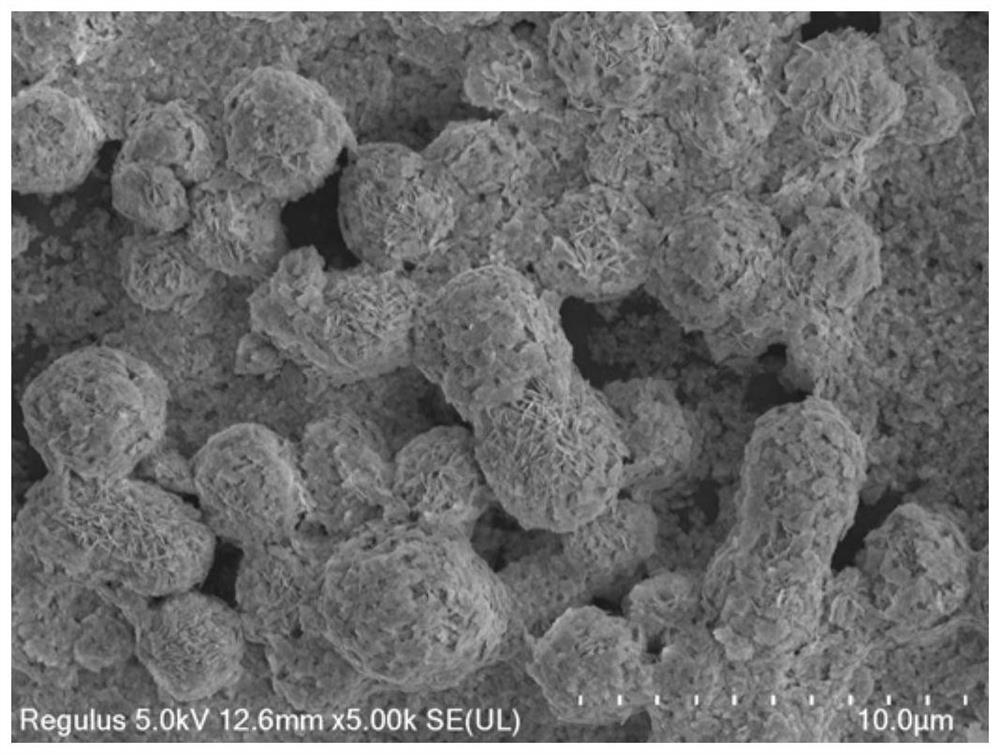

[0038] A kind of nano flower spherical Bi-Bi of the present invention 2 o 2 CO 3 The preparation method of composite photocatalyst specifically comprises the following steps:

[0039] Step 1: by the mol ratio of 1:2, sodium citrate (Na 3 C 6 h 5 o 7 2H 2 O) and Bi(NO 3 ) 3 ·5H 2 O dissolved in HNO3 solution, after stirring for 30-90min, use NaOH solution to adjust its pH to 5-5.5, then stir for 30-90min to obtain precursor solution A, and Bi in precursor solution A 3+ The concentration is 0.05-0.2mol / L;

[0040] Step 2: Put the precursor solution A in a hydrothermal reaction kettle, the reaction filling ratio is 65-85%, and the temperature is raised from room temperature to 180-200°C in 45-60 minutes, and the reaction is completed after 18-24 hours of heat preservation, and naturally cooled to room temperature, the obtained The precipitate was washed three times with deionized water and absolute ethanol, then dried at a constant temperature of 65-80°C for 10-16 hour...

Embodiment 1

[0053] Step 1: Add 1.2g Na 3 C 6 h 5 o 7 2H 2 O and 3.88g Bi(NO 3 ) 3 ·5H 2 O dissolved in HNO 3 solution, after stirring for 60 minutes, adjust its pH to 5.4 with NaOH solution, and then stir for 60 minutes to obtain precursor solution A;

[0054] Step 2: Put the precursor solution A in a hydrothermal reaction kettle with a reaction filling ratio of 80%, raise the temperature from room temperature to 180°C for 60 minutes, finish the reaction after 18 hours of heat preservation, and naturally cool to room temperature. The obtained precipitate is washed with deionized water and After washing with absolute ethanol three times, dry at a constant temperature of 70 °C for 12 h, and grind to obtain Bi 2 o 2 CO 3 Powder;

[0055] Step 3: Take 0.00025mol NaBH 4 Add it into 20mL deionized water, stir for 30min to get Precursor B;

[0056] Step 4: Take 0.001mol Bi 2 o 2 CO 3 Add the powder into 20mL deionized water, stir for 30min to obtain the precursor solution C;

[...

Embodiment 2

[0059] Step 1: Add 1.2g Na 3 C 6 h 5 o 7 2H 2 O and 3.88g Bi(NO 3 ) 3 ·5H 2 O dissolved in HNO 3 solution, after stirring for 60 minutes, adjust its pH to 5.4 with NaOH solution, and then stir for 60 minutes to obtain precursor solution A;

[0060] Step 2: Put the precursor liquid A in a hydrothermal reaction kettle with a reaction filling ratio of 80%, raise the temperature from room temperature to a reaction temperature of 180°C in 60 minutes, finish the reaction after 18 hours of heat preservation, and naturally cool to room temperature, and the obtained precipitate is washed with deionized water After washing with absolute ethanol for 3 times, dry at 70°C for 12 hours, and grind to obtain Bi 2 o 2 CO 3 Powder;

[0061] Step 3: Take 0.0005mol NaBH 4 Add it into 20mL deionized water, stir for 30min to get Precursor B;

[0062] Step 4: Take 0.001mol Bi 2 o 2 CO 3 Add the powder into 20mL deionized water, stir for 30min to obtain the precursor solution C;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com