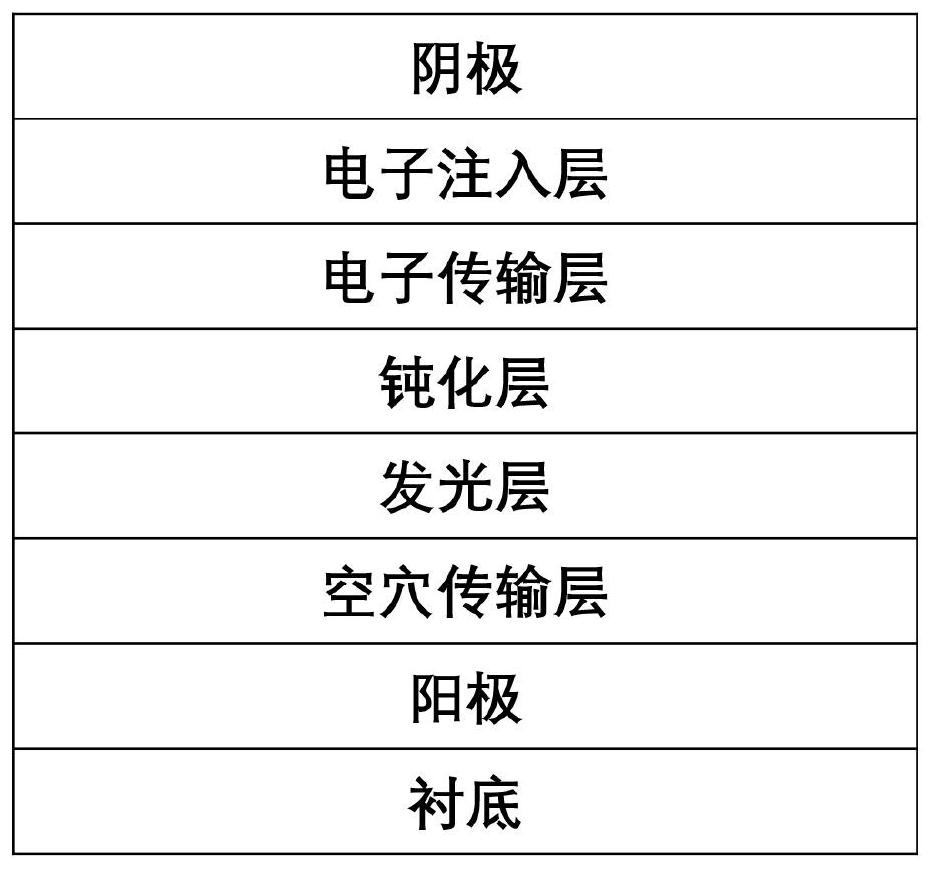

Blue-light perovskite light-emitting diode and preparation method thereof

A light-emitting diode, perovskite technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as poor performance of blue PeLEDs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

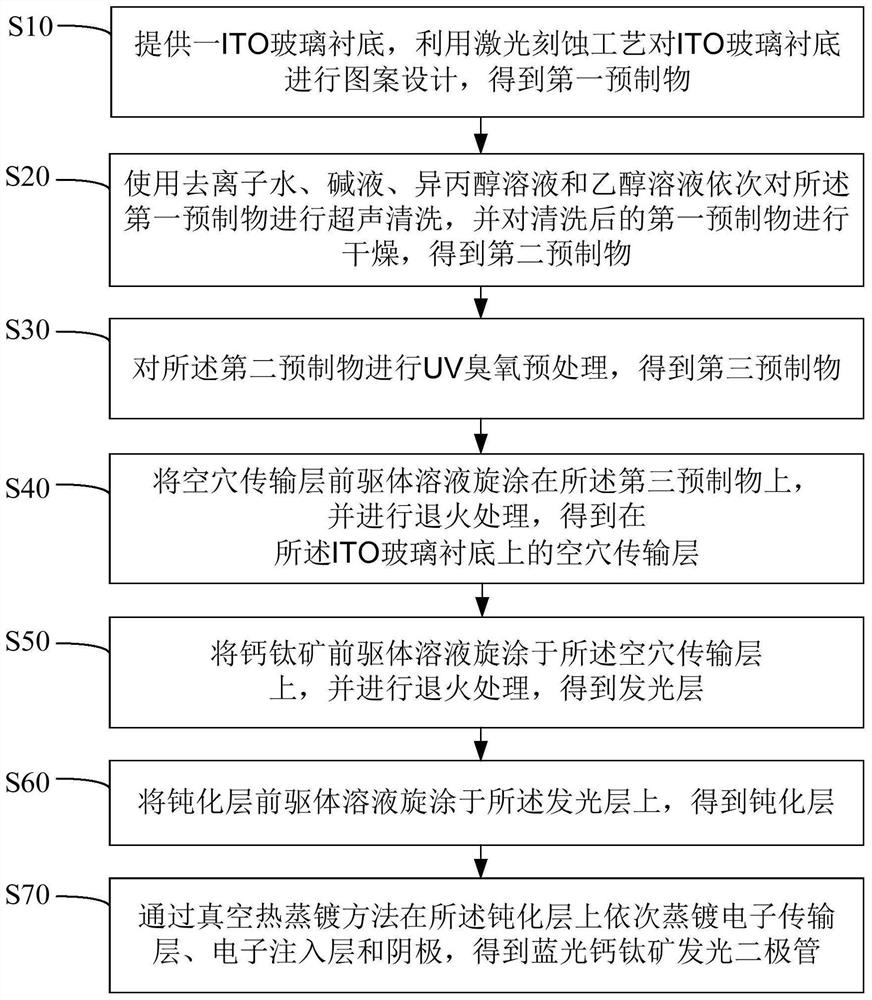

preparation example Construction

[0070] The preparation method of the perovskite precursor solution is as follows: cesium bromide, lead bromide, large group organic halides and thiocyanate additives are dissolved in dimethyl sulfoxide solvent to prepare the perovskite precursor solution . The perovskite precursor solution is used to prepare a perovskite thin film, that is, to prepare a light-emitting layer.

[0071] The preparation method of the passivation layer precursor solution is as follows: the passivation layer material is dissolved in chlorobenzene solvent to prepare the passivation layer precursor solution.

[0072] Further, the thiocyanate additive can be any one of methylammonium thiocyanate additive, guanidine thiocyanate additive, ammonium thiocyanate additive or additives added with guanidine thiocyanate and methylammonium thiocyanate, The layer material can be any one of tri-n-octylphosphine oxide or triphenylphosphine oxide.

[0073] In this embodiment, when the passivation material used in ...

no. 1 example

[0109] Based on the first embodiment, the second embodiment of the preparation method of the blue light perovskite light-emitting diode of the present invention is proposed. In this embodiment, before step S50, three different perovskite additives of thiocyanate are proposed as follows The preparation process of the precursor solution specifically includes:

[0110] Step A1, dissolving cesium bromide, lead bromide, macroorganic halide and methylammonium thiocyanate additive in dimethyl sulfoxide solvent to obtain the perovskite precursor solution.

[0111] In this example, before the light-emitting layer is prepared, the perovskite precursor solution is prepared first, and there are many ways to prepare the perovskite precursor solution, and different components can be equipped to obtain different perovskite precursors solution. This embodiment proposes the first preparation process of the perovskite precursor solution, the first preparation process of the perovskite precurso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com