Microcapsule powder with high embedding rate, and preparation technology

A technology of microcapsule powder and high encapsulation, applied in the field of food processing, can solve the problems of high embedding rate, unreachable, poor comprehensive performance of oxygen barrier, etc., and achieve the effect of high nutrient content and thorough sterilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

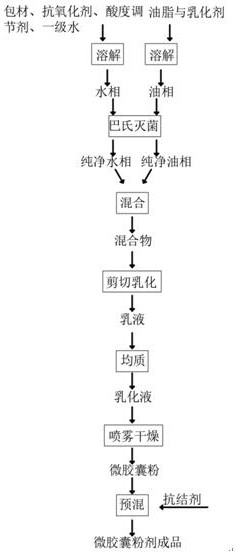

[0030] see figure 1 , the present invention provides a technical solution: a microcapsule powder with a high embedding rate and a preparation process, comprising the following steps:

[0031] Step (1) Dissolving: Add 400 parts of maltodextrin, 21 parts of tea polyphenols and 10 parts of calcium lactate into the first-grade water, stir for 8 minutes until dissolved to obtain the water phase, mix 350 parts of DHA oil with 310 parts of propylene glycol fatty acid ester Dissolve for 5-10min to obtain the oil phase;

[0032] Step (2) pasteurization: pasteurize the water phase and oil phase obtained in step (1) for 30 minutes to obtain a pure oil phase and a pure water phase;

[0033] Step (3) Shear emulsification: add the pure oil phase obtained in step (2) to the pure water phase obtained in step (2) to prepare a mixture, and the shear speed of the mixture is 13000rpm, and the shear time is Under the environment of 20min, carry out shear emulsification and make emulsion;

[003...

Embodiment 2

[0039] see figure 1 , the present invention provides a technical solution: a microcapsule powder with a high embedding rate and a preparation process, comprising the following steps:

[0040] Step (1) Dissolving: Add 430 parts of galacto-oligosaccharides, 24 parts of calcium ascorbate and 13 parts of fumaric acid into primary water, stir for 8 minutes until dissolved to obtain a water phase, and mix 360 parts of DHA oil with 300 parts of octenylsuccinic acid Sodium starch was mixed and dissolved for 5-10 minutes to obtain the oil phase;

[0041] Step (2) pasteurization: pasteurize the water phase and oil phase obtained in step (1) for 30 minutes to obtain a pure oil phase and a pure water phase;

[0042] Step (3) Shear emulsification: add the pure oil phase obtained in step (2) to the pure water phase obtained in step (2) to prepare a mixture, and the shear speed of the mixture is 14000rpm, and the shear time is 18min Under the environment of shear emulsification, the emulsi...

Embodiment 3

[0048] see figure 1 , the present invention provides a technical solution: a microcapsule powder with a high embedding rate and a preparation process, comprising the following steps:

[0049] Step (1) Dissolution: Add 400 parts of maltodextrin, 21 parts of tea polyphenols and 10 parts of calcium lactate into primary water, stir for 8 minutes until dissolved to obtain the water phase, mix 350 parts of ARA oil with 310 parts of propylene glycol fatty acid ester Dissolve for 5-10min to obtain the oil phase;

[0050] Step (2) pasteurization: pasteurize the water phase and oil phase obtained in step (1) for 30 minutes to obtain a pure oil phase and a pure water phase;

[0051] Step (3) Shear emulsification: add the pure oil phase obtained in step (2) to the pure water phase obtained in step (2) to prepare a mixture, and the shear speed of the mixture is 13000rpm, and the shear time is Under the environment of 20min, carry out shear emulsification and make emulsion;

[0052] Step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com