Selenium sulfide composite powder for hair washing

A technology of selenium sulfide and compound powder, applied in the field of daily chemicals, can solve the problems of many quartz wastes, high equipment requirements and high comprehensive production cost, and achieve the effects of inhibiting Malassezia, reducing oil secretion and reducing dandruff.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] A kind of selenium sulfide composite powder for shampoo, described selenium sulfide composite powder is prepared by following steps:

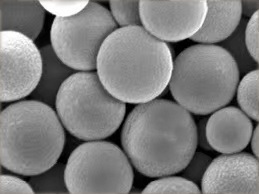

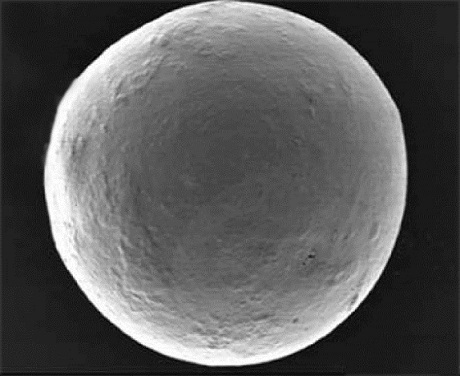

[0057] (1) Preparation of carbon spheres by hydrothermal method.

[0058] Dissolve 10% of glucose in 100ml of deionized water, add 1% of formaldehyde, use sodium hydroxide to adjust the pH to 8, transfer to the hydrothermal reaction kettle after stirring, at 200 o C under water heat treatment for 12 hours to obtain a tan suspension, which was filtered, washed and dried to obtain carbon sphere particles.

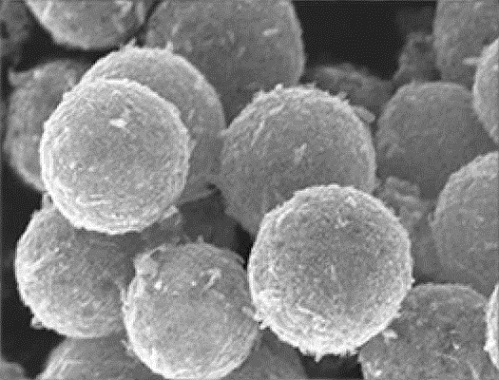

[0059] (2) Configure the electrolyte, and deposit nano-selenium carbon spheres on the surface of the carbon spheres by electrochemical treatment.

[0060] The configuration electrolyte is composed of sodium selenite, sodium chloride, boric acid, surfactant, carbon sphere particles and deionized water, the sodium selenite is 17.3g / L, and the sodium chloride is 10 g / L , boric acid 20g / L, surfactant 0.05 g / L, carbon sphere particles 15g / ...

Embodiment 2

[0071] A kind of selenium sulfide composite powder for shampoo, described selenium sulfide composite powder is prepared by following steps:

[0072] (1) Preparation of carbon spheres by hydrothermal method.

[0073] Dissolve 12.5g of glucose in 100ml of deionized water, add 1.25g of formaldehyde, use sodium hydroxide to adjust the pH to 8.25, transfer to a hydrothermal reaction kettle after stirring, and oC under water heat treatment for 14 hours to obtain a tan suspension, which was filtered, washed and dried to obtain carbon sphere particles.

[0074] (2) Configure the electrolyte, and deposit nano-selenium carbon spheres on the surface of the carbon spheres by electrochemical treatment.

[0075] The configuration electrolyte is composed of sodium selenite, sodium chloride, boric acid, surfactant, carbon sphere particles and deionized water, the sodium selenite is 34.6g / L, and the sodium chloride is 11g / L, The boric acid is 22.5 g / L, the surfactant is 0.075 g / L, and the ca...

Embodiment 3

[0086] A kind of selenium sulfide composite powder for shampoo, described selenium sulfide composite powder is prepared by following steps:

[0087] (1) Preparation of carbon spheres by hydrothermal method.

[0088] Dissolve 15g of glucose in 100ml of deionized water, add 1.5g of formaldehyde, use sodium hydroxide to adjust the PH concentration to 8.5, transfer to the hydrothermal reaction kettle after stirring, and heat at 220 o C under water heat treatment for 16 hours to obtain a tan suspension, which was filtered, washed and dried to obtain carbon sphere particles.

[0089] (2) Configure the electrolyte, and deposit nano-selenium carbon spheres on the surface of the carbon spheres by electrochemical treatment.

[0090] The configuration electrolyte is composed of sodium selenite, sodium chloride, boric acid, surfactant, carbon sphere particles and deionized water, the sodium selenite is 51.9g / L, and the sodium chloride is 12 g / L , boric acid is 25 g / L, surfactant is 0.1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com