3, 3-diazidomethyl oxetane-tetrahydrofuran energetic copolyether with alternating multi-block structure and synthesis method thereof

A technology of diazidomethyl oxetane and tetrahydrofuran is applied in 3 fields, and can solve the problems such as the inability to obtain alternating multi-block copolymerization and the need for further optimization of the microscopic sequence structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1.2g of PBAMO (Mn=322, 3.7mmol) was dissolved in 10mL of THF, 2.24g of KOH (40mmol) was added, and the system was transferred to a constant temperature oil bath at 65°C. A THF solution of 1.2 g of tosylate-terminated polytetrahydrofuran (Mn=542, 2.2 mmol) was slowly dropped into the above reaction system. After the dropwise addition, the system continued to react at 65°C for 18 hours. Then filter and rotary evaporate, the crude product was dissolved in dichloromethane, washed with distilled water until neutral. Then dry with anhydrous magnesium sulfate, filter with suction, and rotary evaporate, then add petroleum ether with a boiling point of 60-90°C and methanol to wash and rotary evaporate to obtain a yellow viscous substance (0.82g)

[0026] Structure Identification:

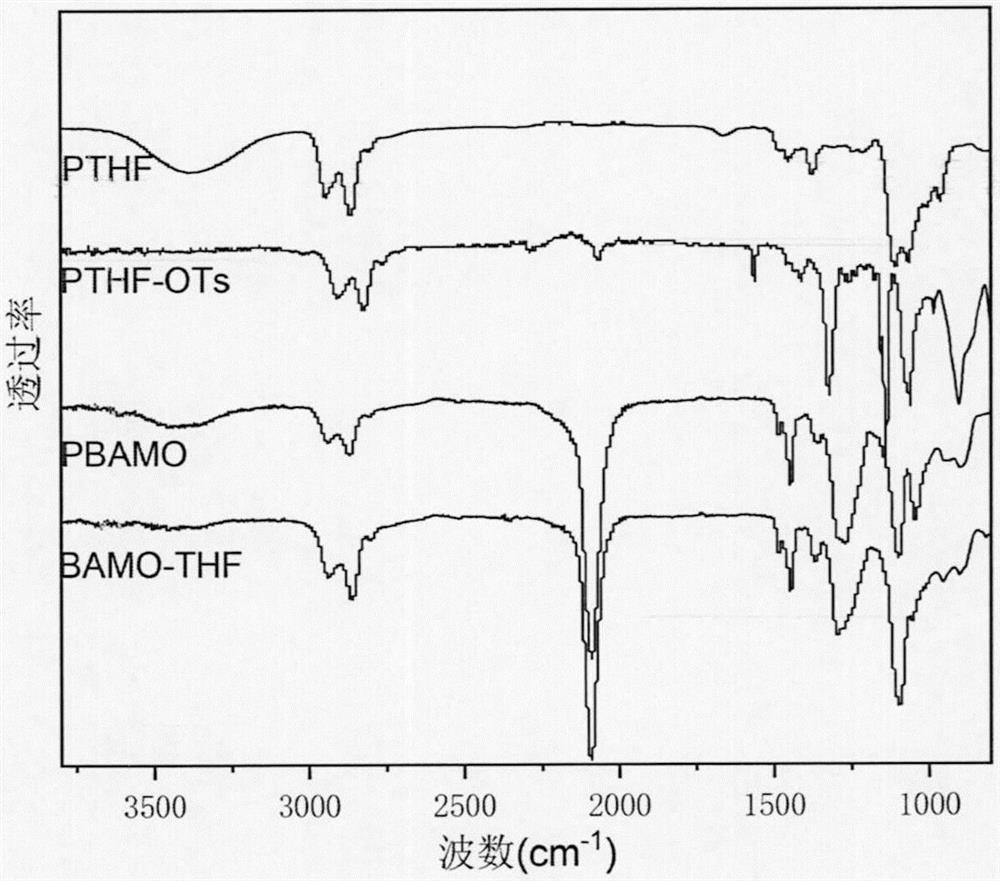

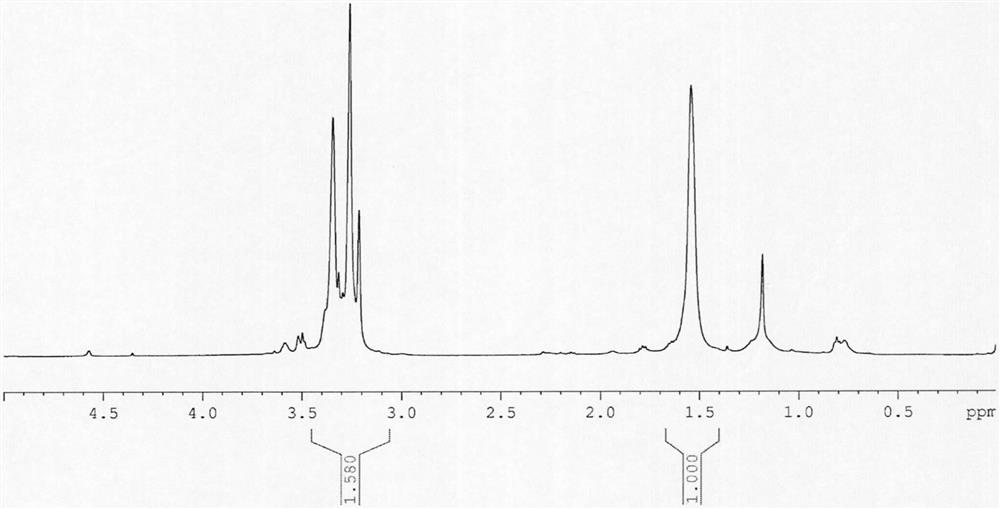

[0027] FT-IR infrared: After polytetrahydrofuran is p-tosylated to obtain terminal tosylate polytetrahydrofuran, the infrared hydroxyl 3000-3500cm -1 disappear, proving that the end group of PTHF ha...

Embodiment 2

[0031] 1.5g of PBAMO (Mn=448, 3.3mmol) was dissolved in 20mL of THF, 2.57g of KOH (40mmol) was added, and the system was transferred to a constant temperature oil bath at 65°C. A THF solution of 1.2 g of tosylate-terminated polytetrahydrofuran (Mn=542, 2.2 mmol) was slowly dropped into the above reaction system, and the reaction was continued at 65° C. for 24 h after the addition was completed. Then filter and rotary evaporate, the crude product was dissolved in dichloromethane, washed with distilled water until neutral. It was then dried over anhydrous magnesium sulfate, suction filtered, and rotary evaporated, followed by adding petroleum ether with a boiling point of 60-90°C and methanol to wash and rotary evaporated to obtain a yellow sticky substance (0.74 g).

Embodiment 3

[0033] 1.28g of PBAMO (Mn=510, 2.5mmol) was dissolved in 20mL of THF, 2.01g of KOH (40mmol) was added, and the system was transferred to a 65°C constant temperature oil bath. A THF solution of 0.8 g of tosylate-terminated 1,4-butanediol (Mn=398, 2.0 mmol) was slowly dropped into the above reaction system, and the system continued to react at 65° C. for 24 h after the addition was completed. Then filter and rotary evaporate, the crude product was dissolved in dichloromethane, washed with distilled water until neutral. It was then dried with anhydrous magnesium sulfate, suction filtered, and rotary evaporated, followed by adding petroleum ether with a boiling point of 60-90°C and methanol to wash and rotary evaporated to obtain a yellow sticky substance (0.52 g).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com