Porous fluid as well as preparation method and application thereof

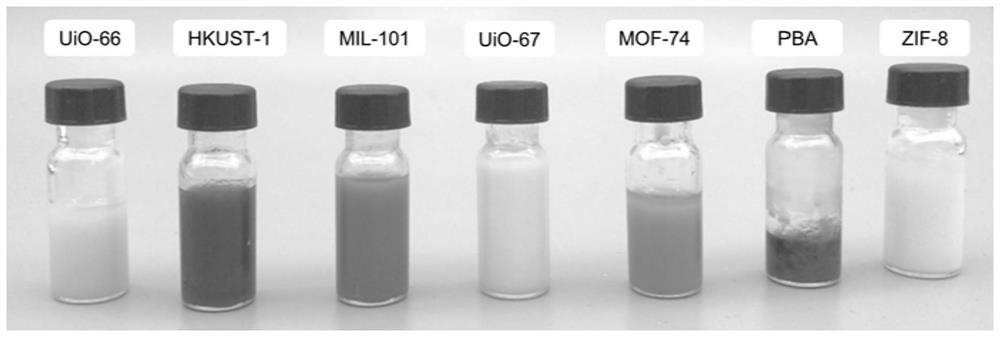

A fluid, ionic liquid technology, applied in the field of porous fluid and its preparation, can solve the problems of poor universality, difficult characterization and modification of pores, unstable colloidal dispersion system, etc., to achieve high colloidal stability, enhanced solvation, mechanical Properties that can be tunable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

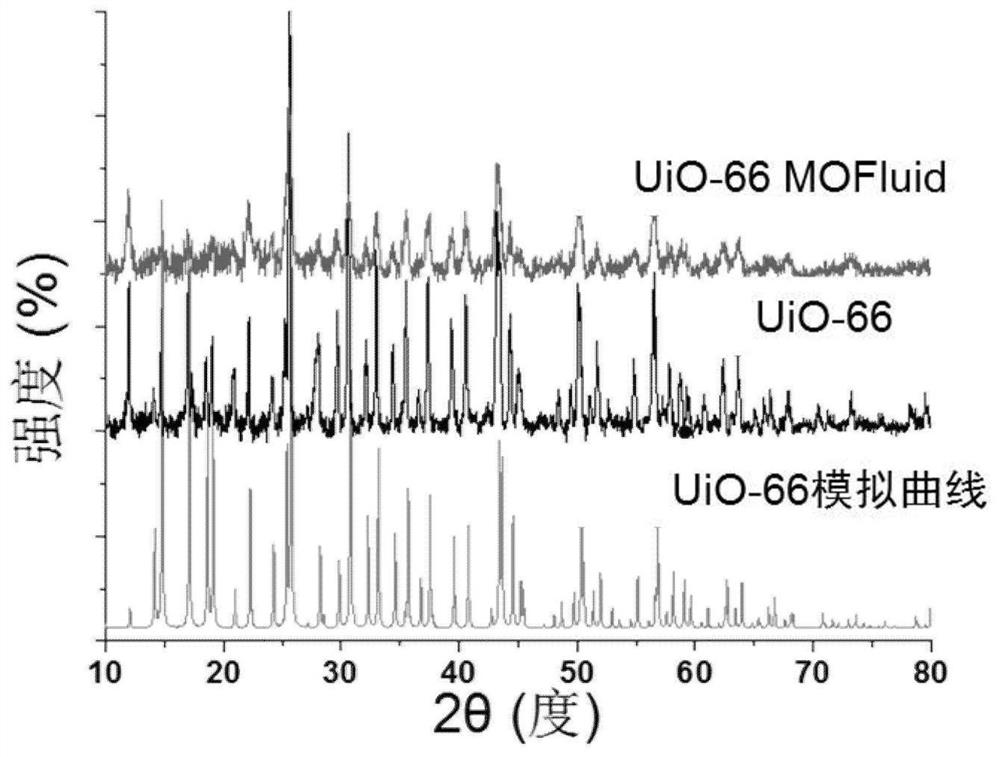

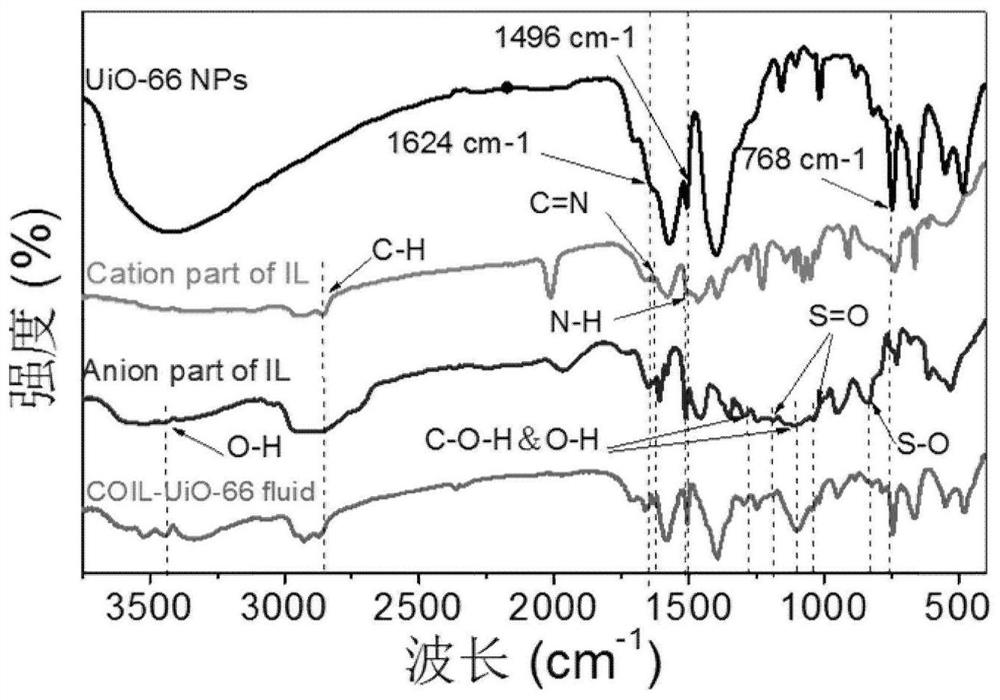

Method used

Image

Examples

Embodiment 1

[0056] The preparation method of the porous fluid of the present embodiment is as follows:

[0057] 1) Synthesis of cationic part (substance A): 2-methylimidazole (116.43mg, 0.0011mol) and N-(3-azide)-N,N-dioctyl-N-methylammonium bromide (339.58mg, 0.001mol) was dissolved in a round bottom flask of 5mlDMF, under the protection of inert gas (nitrogen or argon), add CuBr (43.635mg, 0.0003mol) and PMDETA (109.98mg, 0.0006mol), stirred at room temperature Overnight, the crude product was obtained; the crude product was dissolved in ethyl acetate after removing DMF, and washed three times (purification) with NaOH aqueous solution of EDTA; the ethyl acetate layer was washed with anhydrous NaOH 2 SO 4 After drying, the excess solution was removed by rotary evaporation to obtain the cationic fraction (substance A).

[0058] 2) Synthesis of ionic liquid: put cationic part and PEGS of equal amount in a flask, add 5 times the volume (that is, 5 times the volume of cationic part and PEG...

Embodiment 2

[0068] The preparation method of the porous fluid of the present embodiment is as follows:

[0069] 1) Synthesis of cationic part (substance A): 2-methylimidazole (116.43mg, 0.0011mol) and N-(3-azide)-N,N-dioctyl-N-methylammonium bromide (339.58mg, 0.001mol) was dissolved in a 5ml DMF round bottom flask, under the protection of an inert gas, CuBr (43.635mg, 0.0003mol) and PMDETA (109.98mg, 0.0006mol) were added, stirred overnight at room temperature to obtain a crude product; The crude product was dissolved in ethyl acetate after removing DMF, washed three times with EDTA NaOH aqueous solution; the ethyl acetate layer was washed with anhydrous NaOH 2 SO 4 After drying, the excess solution was removed by rotary evaporation to obtain the cationic fraction (substance A).

[0070] 2) Synthesis of ionic liquids: put cationic moieties and PEGS in equal amounts in a flask, add 5 times the volume of a 1:1 mixed solution of water and ethanol, react overnight at 70°C, and dialyze the ...

Embodiment 3

[0074] The preparation method of the porous fluid of the present embodiment is as follows:

[0075] 1) Synthesis of cationic part (substance A): 2-methylimidazole (116.43mg, 0.0011mol) and N-(3-azide)-N,N-dioctyl-N-methylammonium bromide (339.58mg, 0.001mol) was dissolved in a 5ml DMF round bottom flask, under the protection of an inert gas, CuBr (43.635mg, 0.0003mol) and PMDETA (109.98mg, 0.0006mol) were added, stirred overnight at room temperature to obtain a crude product; The crude product was dissolved in ethyl acetate after removing DMF, washed three times with EDTA NaOH aqueous solution; the ethyl acetate layer was washed with anhydrous NaOH 2 SO 4 After drying, the excess solution was removed by rotary evaporation to obtain the cationic fraction (substance A).

[0076] 2) Synthesis of ionic liquids: put cationic moieties and PEGS in equal amounts in a flask, add 5 times the volume of a 1:1 mixed solution of water and ethanol, react overnight at 70°C, and dialyze the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com