Nanosheet composite coating as well as preparation method and application thereof

A composite coating and nanosheet technology, applied in the field of coatings, can solve problems such as coating shrinkage, coating life shortening, and weakening coating resistance to corrosive media, etc., to extend the path, ensure isolation effect, and good physical barrier effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] An embodiment of the nanosheet composite coating and its preparation method and application according to the present invention, the preparation method of the nanosheet composite coating comprises the following steps:

[0037] (1) Add 25 mg of boron nitride powder, a two-dimensional nanosheet material with a size of 0.5 to 50 μm, and 0.1 g of urushiol into 2.5 g of xylene, and obtain a boron nitride nanosheet dispersion after ultrasonic treatment for 4 hours;

[0038] (2) Add 10g of E44 epoxy resin to the nanosheet dispersion, and stir it evenly by mechanical stirring; finally add 8g of polyamide 650 curing agent, stir for 5 minutes and quickly put it into the defoamer, set the speed to 1500r / min, vacuum degree is 95.8kPa and defoaming 15min, promptly obtains described nanosheet composite coating.

[0039] The metal product used in this example is a Q235 carbon steel sheet with a specification of 5cm×5cm×1mm. The surface of the carbon steel sheet is polished with 180-me...

Embodiment 2

[0045] An embodiment of the nanosheet composite coating and its preparation method and application in the present invention, the difference between this embodiment and Example 1 is that the two-dimensional nanosheet material is graphene with a size of 0.5-50 μm.

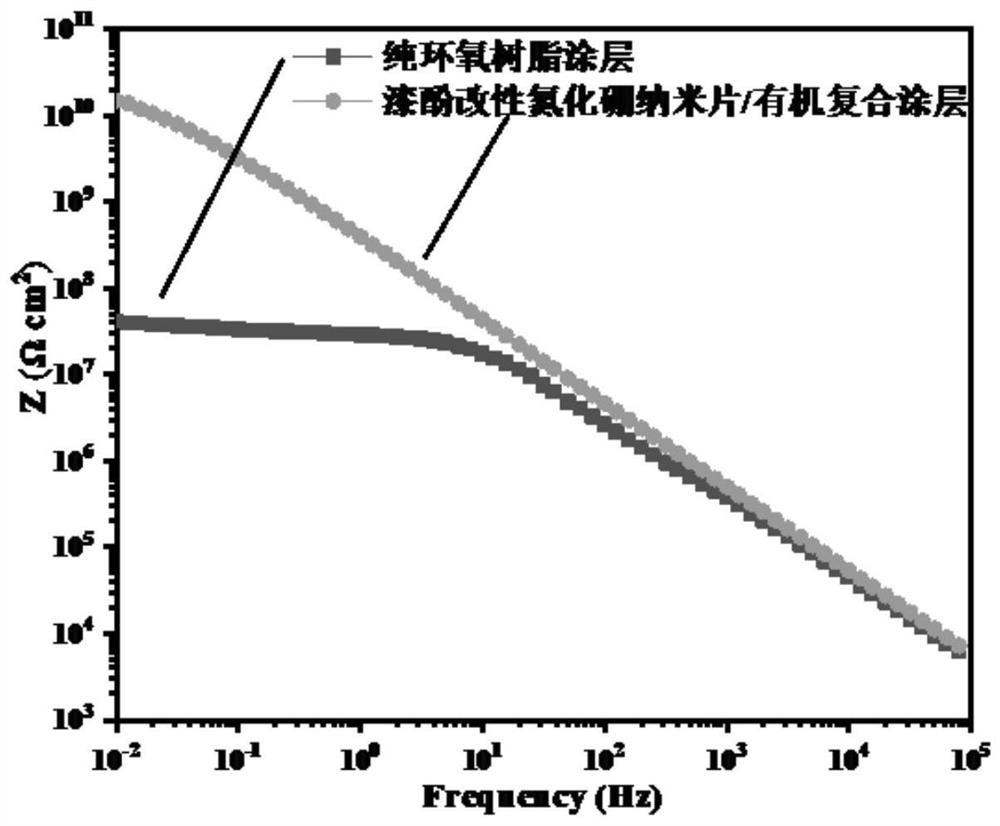

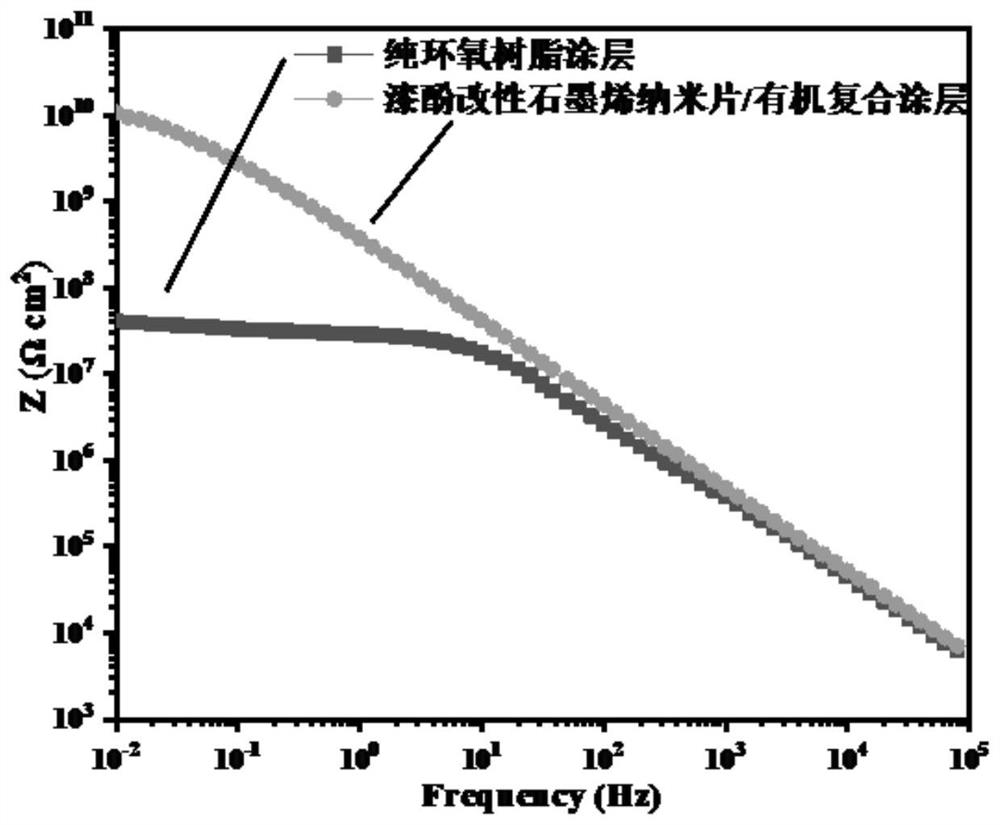

[0046] Application and testing are carried out to the nano sheet composite coating obtained in this embodiment, and described application and testing method are with embodiment 1, and test result is as follows figure 2 shown.

[0047] from figure 2 It can be seen that the coating of pure epoxy resin coating is soaked in 3.5wt% NaCl aqueous solution for 50 days |Z| f=0.01Hz is 4.096×10 7 Ω·cm 2 , urushiol-modified boron nitride nanosheet / organic composite coating after soaking in 3.5wt% NaCl aqueous solution for 50 days |Z| f=0.01Hz is 1.056×10 10 Ω·cm 2 , significantly improving the corrosion resistance of the coating.

Embodiment 3

[0049] An embodiment of the nanosheet composite coating and its preparation method and application in the present invention, the difference between this embodiment and Example 1 is that the two-dimensional nanosheet material is tungsten disulfide with a size of 0.5-50 μm.

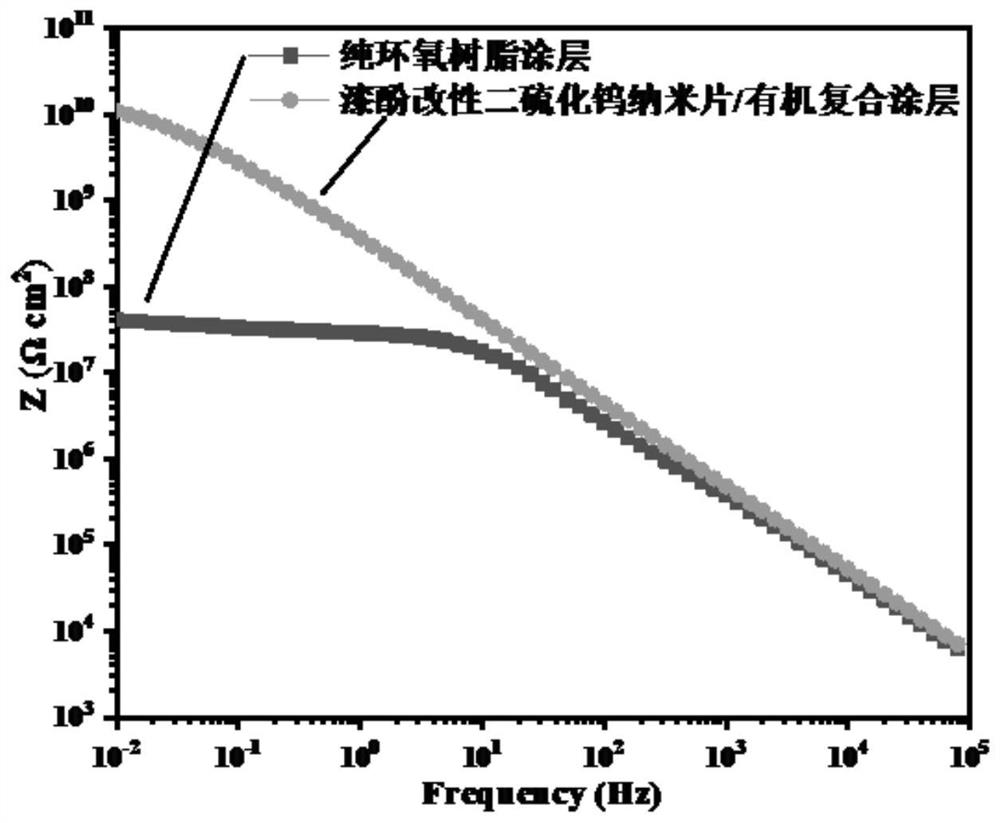

[0050] Application and testing are carried out to the nano sheet composite coating obtained in this embodiment, and described application and testing method are with embodiment 1, and test result is as follows image 3 shown.

[0051] from image 3 It can be seen that the coating of pure epoxy resin coating is soaked in 3.5wt% NaCl aqueous solution for 50 days |Z| f=0.01Hz is 4.096×10 7 Ω·cm 2 , urushiol-modified boron nitride nanosheet / organic composite coating after soaking in 3.5wt% NaCl aqueous solution for 50 days |Z| f=0.01Hz is 1.085×10 10 Ω·cm 2 , significantly improving the corrosion resistance of the coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com