System and method for treating organic polluted solid waste through rapid pyrolysis

A technology for organic pollution and solid waste, applied in combustion methods, separation methods, chemical instruments and methods, etc., can solve the problems of large amount of waste gas, high disposal cost, and high difficulty in operating molten salt circulation system, reducing operating costs and improving The effect of pyrolysis rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

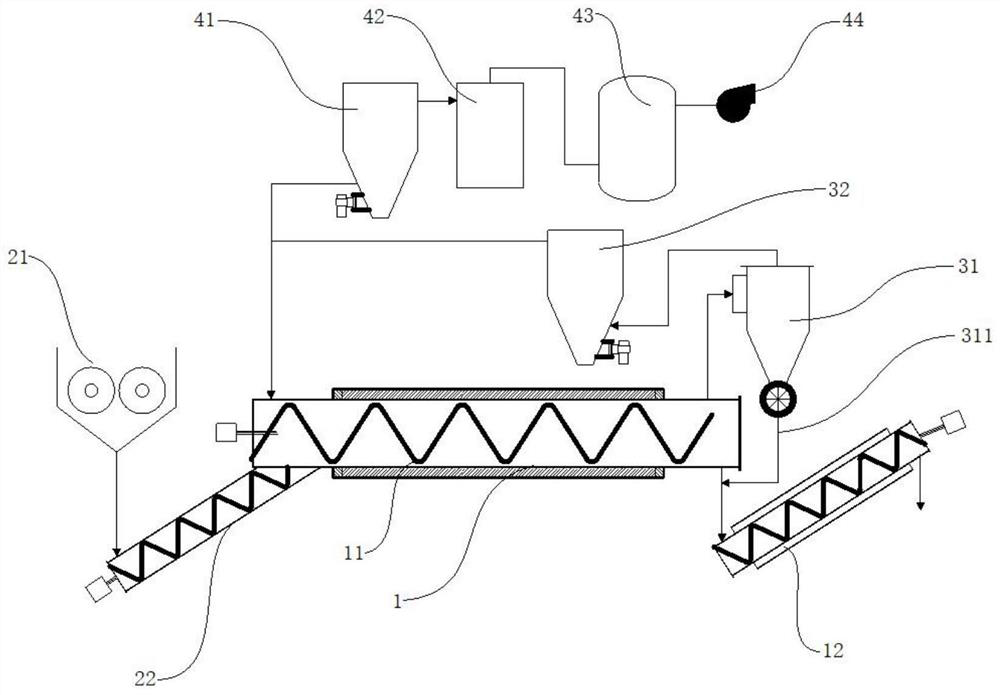

[0026] as attached figure 1 : A fast pyrolysis treatment system for organically polluted solid waste, comprising a material pretreatment unit, a fast pyrolysis reaction unit, a thermal oxidation unit and a tail gas treatment unit; the discharge end of the material pretreatment unit corresponds to the fast pyrolysis reaction unit The feed end of the feed; the fast pyrolysis reaction unit is composed of a horizontally arranged pyrolysis tube 1, and the inside of the pyrolysis tube 1 is provided with an auger 11, and the auger 11 is driven to rotate by an engine; the fast pyrolysis The outlet end of the reaction unit is connected to the inlet end of the thermal oxidation unit, the material separation end of the thermal oxidation unit is connected to the outlet end of the fast pyrolysis reaction unit, and the outlet end of the thermal oxidation unit is connected to the tai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com