Antibacterial and mildew-proof super-hydrophobic oil-water separation paper with high separation flux and preparation method thereof

An antibacterial, antifungal, and flux technology, applied in textiles and papermaking, separation of immiscible liquids, addition of non-polymeric organic compounds, etc. Performance, simple preparation method, good effect of mildew resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] 1) Soak the cellulose fiber paddle and chitosan fiber with deionized water, then perform mechanical beating to obtain cellulose pulp and chitosan fiber with a beating degree of 30°SR and a concentration of 10wt% respectively;

[0043] 2) Dilute the cellulose slurry and chitosan fiber to a concentration of 1wt%; mix the cellulose slurry and chitosan slurry in a mass ratio of 1:2, and stir evenly; take 180g of the mixed slurry, add 0.75 g tannic acid, 0.75mL 3-aminopropyltriethoxysilane, 0.6mL octadecyltriethoxysilane, 20mL ethanol, stir well, and react at room temperature for 12h;

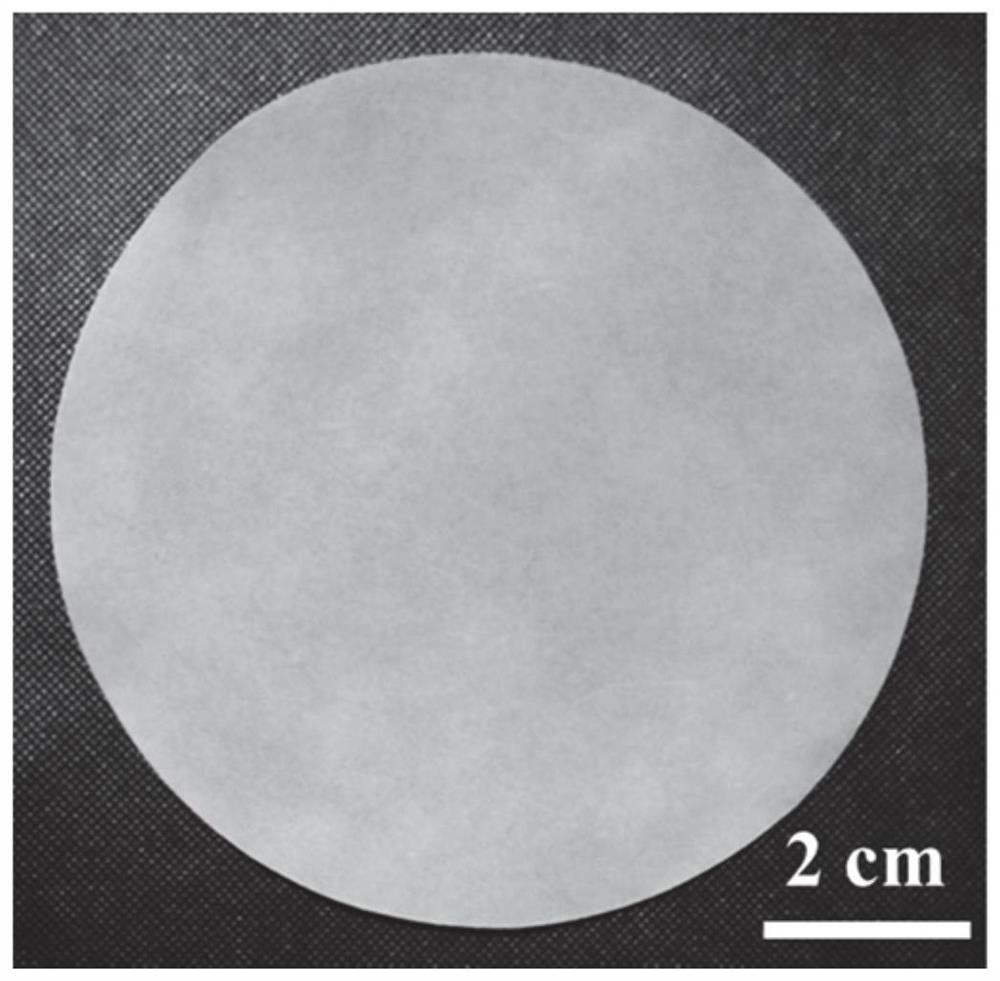

[0044] 3) Using a Kaiser method sheet machine, the fully reacted slurry was sheeted into a circular paper sheet, and dried in a paper dryer at a temperature of 60°C for 1 hour to obtain a superhydrophobic paper.

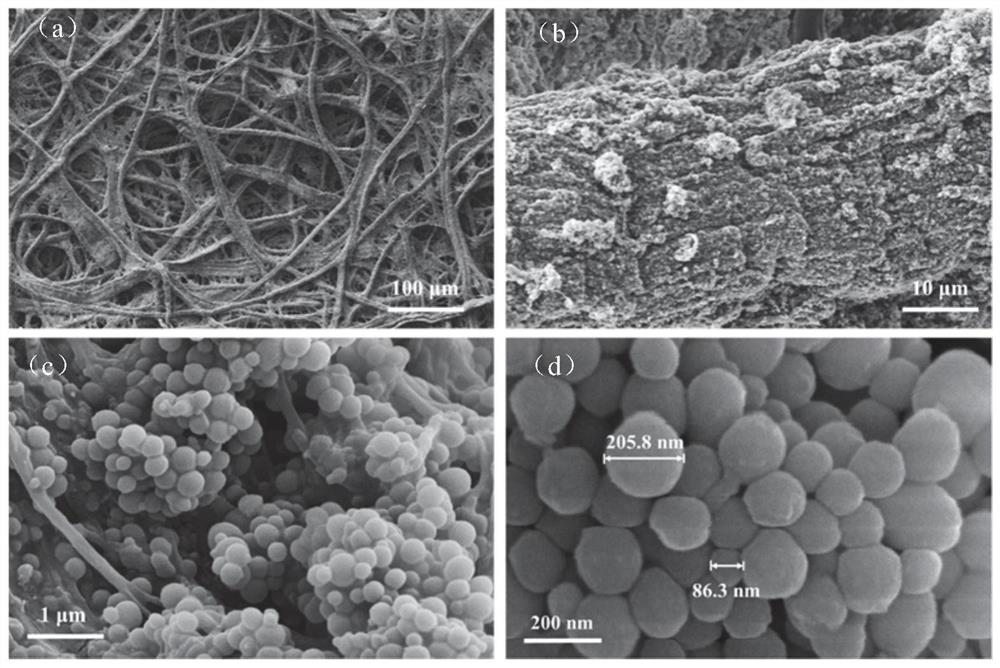

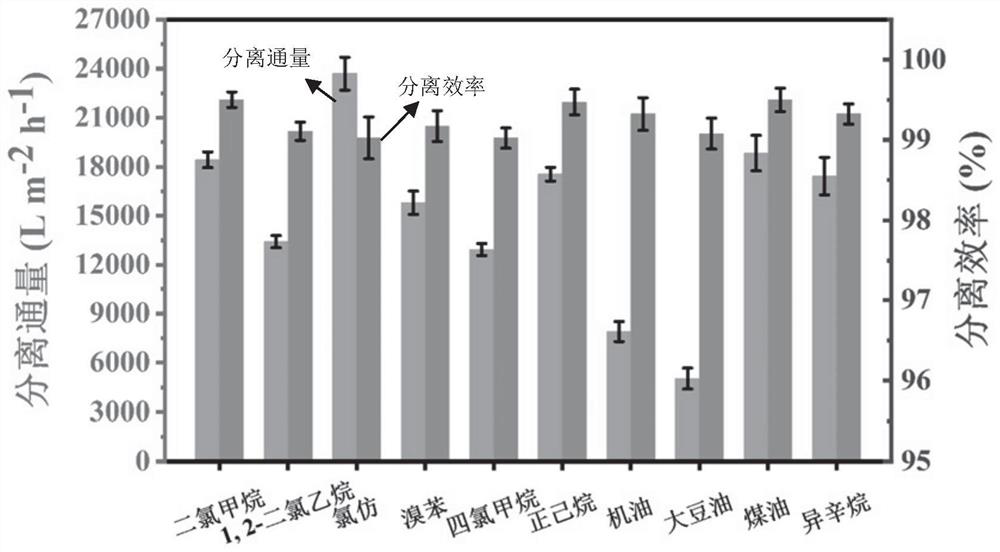

[0045] The quality of gained superhydrophobic paper is 2.6g, and area is 196.3cm 2 , a thickness of 165 μm, a water contact angle of 155°, and a water rolling angle of 8°. Applyin...

Embodiment 2

[0054] 1) Soak the cellulose fiber paddle and chitosan fiber with deionized water, then perform mechanical beating to obtain a beating degree of 45 ° SR, a concentration of cellulose pulp and chitosan fiber of 10 wt %;

[0055] 2) Dilute the cellulose slurry and chitosan fiber to a concentration of 1 wt%. Mix the cellulose slurry and the chitosan slurry according to the mass ratio of 1:1.5, and stir evenly; take 190g of the mixed slurry, add 0.55g of tannic acid, 0.55mL of 3-aminopropyltrimethoxysilane, 0.65 mL hexadecyltriethoxysilane, 20mL ethanol, stir well, react at room temperature for 16h;

[0056] 3) Using a Kaiser method sheet machine, the fully reacted slurry was sheeted into a circular paper sheet, and dried in a paper dryer at a temperature of 70°C for 1.5 hours to obtain a superhydrophobic paper.

[0057] The quality of gained superhydrophobic paper is 2.5g, and area is 186.7cm 2 , a thickness of 176 μm, a water contact angle of 153°, and a water rolling angle of...

Embodiment 3

[0059] 1) Soak the cellulose fiber paddle and chitosan fiber with deionized water, then perform mechanical beating to obtain a beating degree of 50 ° SR, and a concentration of 10 wt% cellulose pulp and chitosan fiber;

[0060] 2) Dilute the cellulose slurry and chitosan fiber to a concentration of 1wt%; mix the cellulose slurry and chitosan slurry in a ratio of 1:1 according to the mass ratio, and stir evenly; get 180g of the mixed slurry, add 0.8g tannic acid, 0.8mL 3-aminopropyltriethoxysilane, 0.7mL octadecyltrimethoxysilane, 20mL ethanol, stir well, and react at room temperature for 14h;

[0061] 3) Using a Kaiser method sheet machine, the fully reacted slurry was sheeted into a circular paper sheet, and dried in a paper dryer at a temperature of 65°C for 1 hour to obtain a superhydrophobic paper.

[0062] The quality of the obtained superhydrophobic paper is 2.7g, and the area is 210.7cm 2 , a thickness of 173 μm, a water contact angle of 155°, and a water rolling angle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com