Cobalt and nitrogen co-doped carbon nanosheet material and preparation and application thereof

A carbon nanosheet, co-doping technology, applied in the field of electrochemistry, can solve the problems of failure to emphasize catalytic performance, large temperature influence, etc., and achieve the effects of excellent oxygen reduction activity, high porosity, and good electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

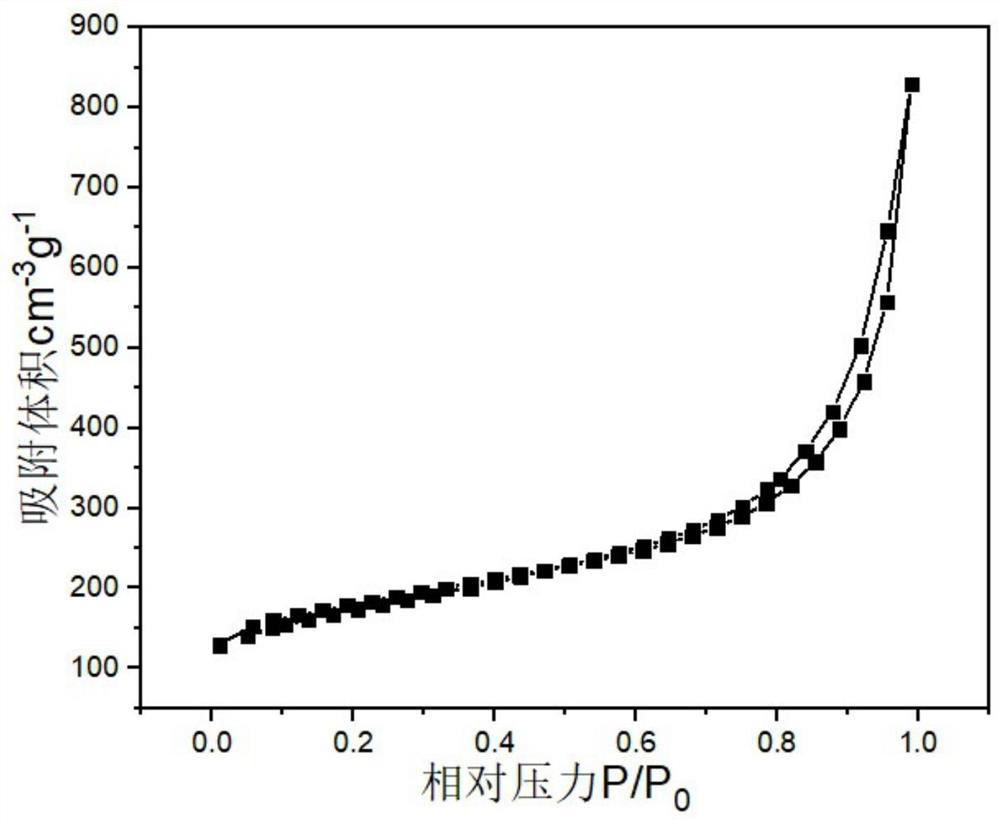

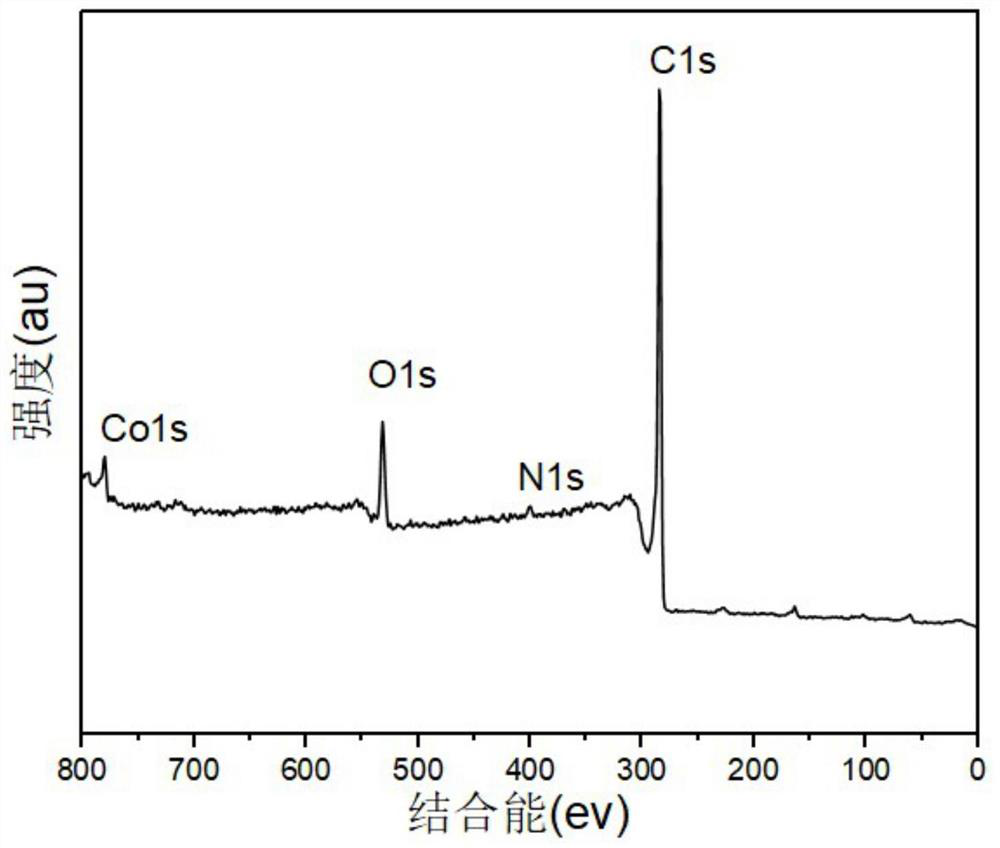

[0050] A cobalt and nitrogen co-doped carbon nanosheet material, the carbon doping amount in the cobalt and nitrogen co-doped carbon nanosheet material is 87.44wt%, the cobalt doping amount is 0.99wt%, and the oxygen doping amount is 8.4wt% %, nitrogen doping amount is 3.17wt%.

[0051] Prepared by the following steps:

[0052] Weigh 1g of lactose monohydrate, 0.5g of zinc nitrate hexahydrate, and 43.8mg of cobalt nitrate hexahydrate and dissolve them in 5ml of deionized water, stir and mix evenly without obvious suspended particles, put them into a blast drying oven, and heat to 220°C rapidly , keep it warm for 20min, and get a brown-black foamy sample. Put the sample in a ceramic boat, put it into a tube furnace, and heat it at 2℃min in a nitrogen atmosphere. -1 Calcined at a heating rate of 800°C, held for 120 minutes, and cooled to room temperature, the cobalt and nitrogen co-doped carbon nanosheet material was obtained.

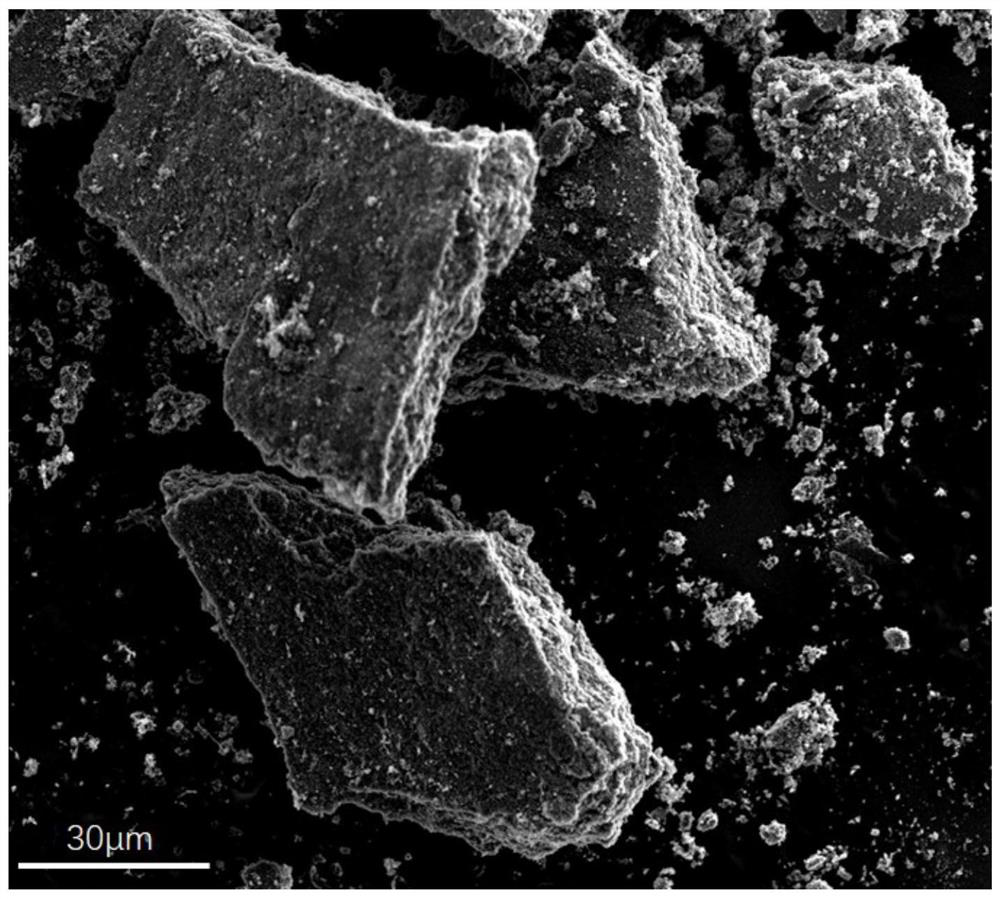

[0053] Depend on figure 1 It can be seen in the...

Embodiment 2

[0060] A cobalt and nitrogen co-doped carbon nanosheet material, the carbon doping amount in the cobalt and nitrogen co-doped carbon nanosheet material is 94.51wt%, the nitrogen doping amount is 2.38wt%, and the oxygen doping amount is 3.11wt% %, cobalt doping amount is 0wt%. Prepared by the following steps:

[0061] Weigh 1g of lactose monohydrate and 0.5g of zinc nitrate hexahydrate, dissolve them in 5ml of deionized water, stir and mix evenly, without obvious suspended particles, put them into a blast drying oven, heat rapidly to 220°C, and keep warm for 30min to obtain brown For black foamy samples, put the sample in a ceramic boat, put it into a tube furnace, and heat it at 2°C min in a nitrogen atmosphere. -1 Calcined at a heating rate of 850°C, held for 200 minutes, and cooled to room temperature, the cobalt and nitrogen co-doped carbon nanosheet material was obtained. Depend on Figure 5 It can be seen that when the voltage is -0.2003V, the cyclic voltammetry curve ...

Embodiment 3

[0063] A cobalt and nitrogen co-doped carbon nanosheet material, the carbon doping amount of the cobalt and nitrogen co-doped carbon nanosheet material is 93.76wt%, the nitrogen doping amount is 1.57wt%, and the oxygen doping amount is 4.16wt% , cobalt doping amount is 0.51wt%, adopts the following steps to prepare:

[0064] Weigh 1g of lactose monohydrate, 0.5g of zinc nitrate hexahydrate, and 21.9mg of cobalt nitrate hexahydrate and dissolve them in 5ml of deionized water, stir and mix evenly without obvious suspended particles, put them into a blast drying oven, and heat to 220°C rapidly , keep it warm for 40min, and get a brown-black foamy sample. Put the sample in a ceramic boat, put it into a tube furnace, and heat it at 2°C min in a nitrogen atmosphere. -1 Calcined at a heating rate of 900°C, held for 240 minutes, and cooled to room temperature, the cobalt and nitrogen co-doped carbon nanosheet material was obtained. Depend on Figure 5 It can be seen that when the vo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com