Preparation method of membrane-like high-molecular water-absorbent resin

A polymer water-absorbing and resin-based technology, applied in the field of sanitary products, can solve problems such as poor liquid absorption performance and toxic components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

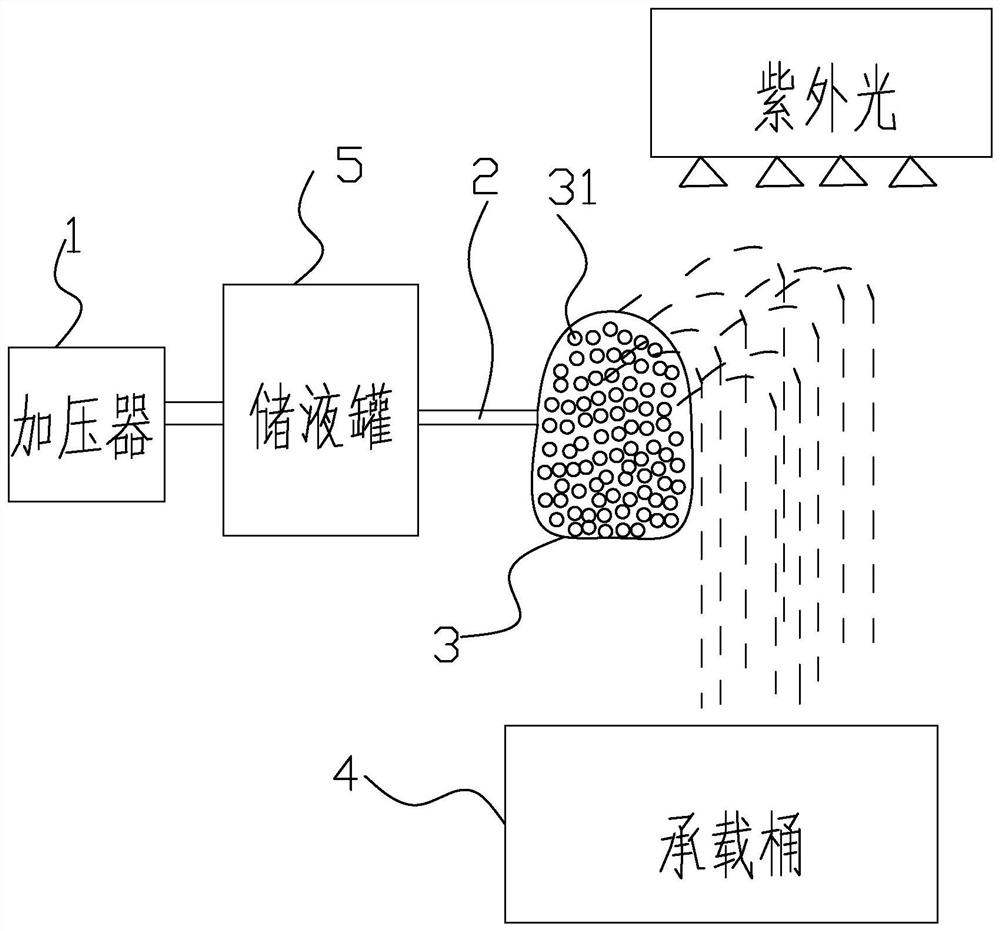

Image

Examples

Embodiment 1

[0035] A method for preparing a film-like polymer water-absorbent resin, comprising the following preparation steps:

[0036] (1) The preparation of acrylic acid monomer solution: get the acrylic acid of 100 weight parts, the sodium hydroxide of 30 weight parts, the sodium trimetaphosphate of 3 weight parts, add the deionized water of 200 weight parts, stir;

[0037] (2) Deoxygenation treatment: the acrylic acid monomer solution prepared in step (1) is sent into a stirring tank, which has a mechanical stirring rod in the stirring tank, and the top of the stirring tank is provided with a nitrogen delivery pipe for feeding nitrogen, By starting the mechanical stirring rod, and continuously blowing nitrogen gas during the stirring process to remove the oxygen in the solution; the stirring time is 30min;

[0038] (3) Preparation of chitosan solution: get 12 parts by weight of chitosan, add mass solubility to be 1% in acetic acid solution, dissolve chitosan by continuous stirring f...

Embodiment 2

[0045] A method for preparing a film-like polymer water-absorbent resin, comprising the following preparation steps:

[0046] (1) The preparation of acrylic acid monomer solution: get the acrylic acid of 100 weight parts, the sodium hydroxide of 30 weight parts, the sodium trimetaphosphate of 3 weight parts, add deionized water, stir;

[0047] (2) Deoxygenation treatment: in the acrylic acid monomer solution that step (1) makes, feed nitrogen to remove the oxygen in the solution;

[0048] (3) Preparation of chitosan solution: get 18 parts by weight of chitosan, add mass solubility to 1% acetic acid solution, dissolve chitosan by continuous stirring for 15min, and continue nitrogen gas to make chitosan solution Oxygen removal in the medium; the temperature is controlled at 0°C;

[0049] (4) Preparation of acrylamide monomer solution: take 70 parts by weight of acrylamide, 20 parts by weight of sodium hydroxide, and 5 parts by weight of sodium trimetaphosphate, add deionized wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com