Flexible high-temperature-resistant transmission signal cable and preparation method thereof

A technology for signal transmission and high temperature resistance, which is applied in the field of soft high temperature resistant transmission signal cables and their preparation, which can solve the problems of poor flexibility and high temperature resistance of cable protective sleeves, and achieve the effects of improving filling performance, increasing strength, and increasing layer spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

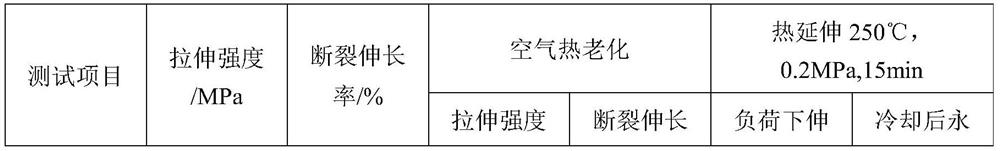

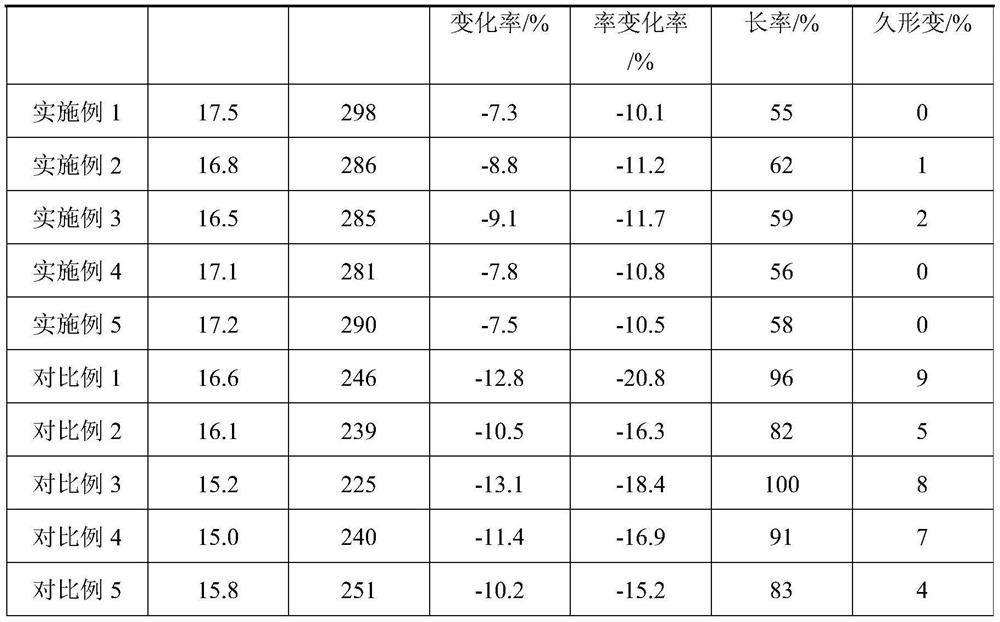

Examples

Embodiment 1

[0022] A flexible high-temperature-resistant transmission signal cable, comprising a central conductor and a protective sheath wrapped around the central conductor, the protective sheath comprising the following components in parts by weight: 50 parts of nitrile rubber, 28 parts of fluorosilicone rubber, 3 parts of benzoyl peroxide 40 parts of polyvinyl butyral, 5 parts of coumarone resin, 12 parts of modified vermiculite, 15 parts of antimony oxide, 0.8 parts of cyanosilicone oil, 2 parts of ultraviolet absorber UV-P, 4 parts of heat stabilizer , 12 parts of glass fiber.

[0023] Among them, the heat stabilizer is p-polyisobutylene phenol and p-phenylenediamine, and the mass ratio is 1:8. The modified vermiculite is prepared by the following method: Calcining the vermiculite at a controlled temperature of 1020-1050°C and cooling it to room temperature, adding 0.1 Stir with mol / L hydrofluoric acid, the mass ratio of hydrofluoric acid to vermiculite is 4:1, wash until neutral, ...

Embodiment 2

[0026] A flexible high-temperature-resistant transmission signal cable, comprising a central conductor and a protective sheath wrapped around the central conductor, the protective sheath comprising the following components in parts by weight: 40 parts of nitrile rubber, 30 parts of fluorosilicone rubber, 4 parts of benzoyl peroxide 35 parts of polyvinyl butyral, 8 parts of coumarone resin, 15 parts of modified vermiculite, 10 parts of aluminum hydroxide, 0.5 parts of cyanosilicone oil, 3 parts of ultraviolet absorber UV-O, 6 parts of heat stabilizer parts, glass fiber 14 parts.

[0027] Wherein, wherein, the heat stabilizer is p-polyisobutylene phenol and p-phenylenediamine, and the mass ratio is 1:10, and the modified vermiculite is prepared by the following method: after the vermiculite is calcined at a controlled temperature of 1050-1100°C, it is cooled to room temperature, Add 0.1mol / L hydrofluoric acid and stir, the mass ratio of hydrofluoric acid to vermiculite is 4:1, w...

Embodiment 3

[0030] A flexible high-temperature-resistant transmission signal cable, comprising a central conductor and a protective sheath wrapped around the central conductor, the protective sheath comprising the following components in parts by weight: 60 parts of nitrile rubber, 25 parts of fluorosilicone rubber, 2 parts of benzoyl peroxide 45 parts of polyvinyl butyral, 3 parts of coumarone resin, 10 parts of modified vermiculite, 20 parts of ammonium polyphosphate, 0.5 parts of silicone oil containing cyanide, 3 parts of ultraviolet absorber UV-O, heat stabilizer 3 parts, 8 parts of glass fiber.

[0031] Wherein, wherein, the heat stabilizer is p-polyisobutylene phenol and p-phenylenediamine, the mass ratio is 1:5, and the modified vermiculite is prepared by the following method: the vermiculite is calcined at a controlled temperature of 1000-1040°C and cooled to room temperature, Add 0.1mol / L hydrofluoric acid and stir, the mass ratio of hydrofluoric acid to vermiculite is 3:1, wash...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com