Fluorocarbon coating as well as preparation method and application thereof

A technology of fluorocarbon coatings and fluorocarbon resins, which can be used in anti-corrosion coatings, fire-proof coatings, anti-fouling/underwater coatings, etc., and can solve problems such as poor mechanical properties and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

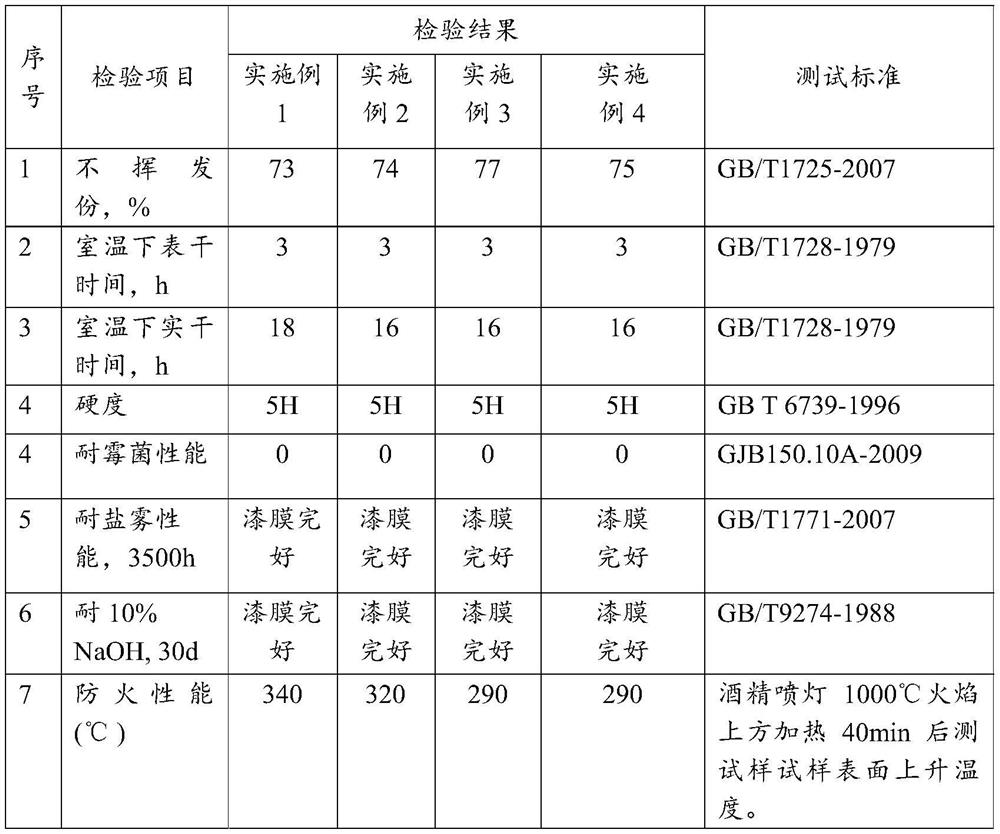

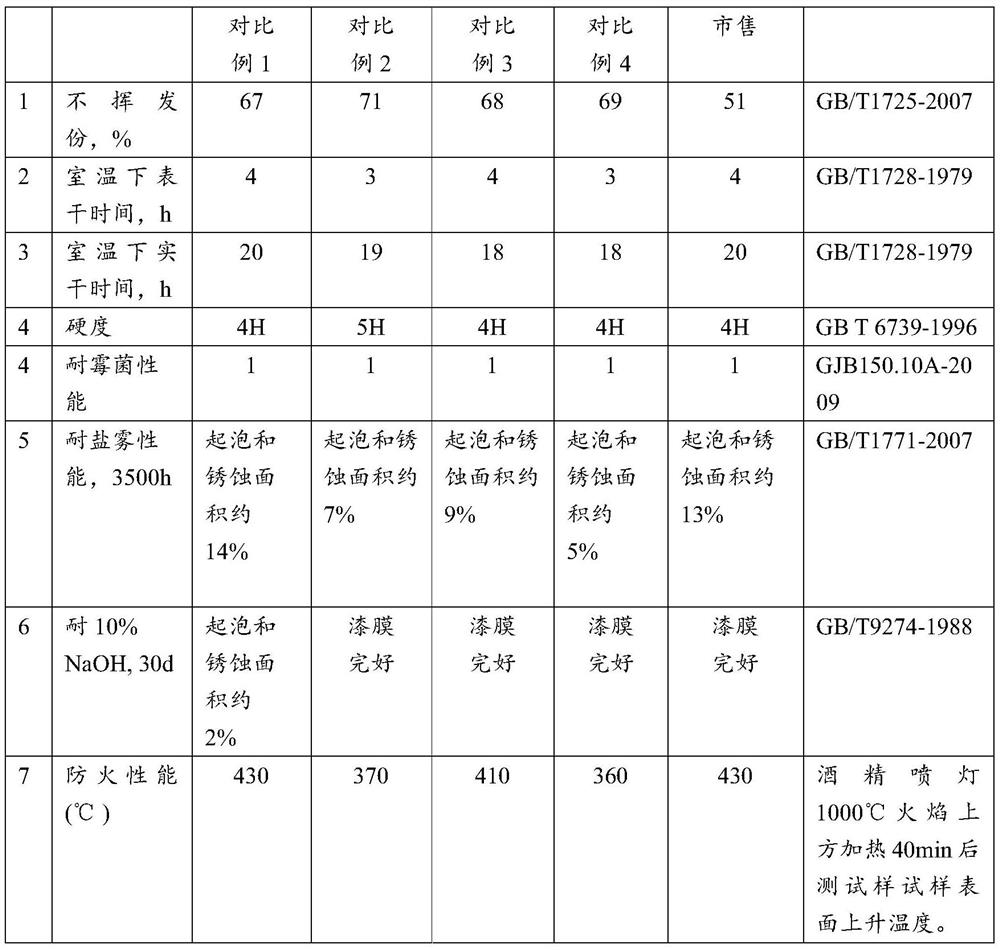

Examples

preparation example Construction

[0029]In addition, this specific embodiment also includes the preparation method of the above-mentioned fluorocarbon coating, including the steps of: mixing component A and component B according to the proportion, and then stirring at a speed of 500r / min-800r / min for 20-30min to obtain the fluorine carbon paint.

[0030] This specific embodiment also includes the application of the above-mentioned fluorocarbon coating or the fluorocarbon coating prepared by the above-mentioned preparation method in making the surface coating of marine ships.

Embodiment 1

[0033] This embodiment proposes a fluorocarbon coating, which is prepared by mixing component A and component B BayerN3390 at a mass ratio of 10:0.8, and then putting it into a high-speed mixer at a speed of 800r / min and stirring for 20 minutes;

[0034] The component A, calculated in parts by weight, includes 33 parts each of HLR-6 and HLR-670 resins, 5 parts of modified whisker zinc oxide, 10 parts of modified silicon dioxide, 0.3 parts of zinc molybdate, zinc borate 4 parts, 0.3 parts of zinc sulfate, 1.1 parts of dispersant BYK161, 0.5 parts of leveling agent BYK399, 0.3 parts of defoamer BYK8801, 9 parts of solvent PMA, 3.5 parts of BAC.

[0035] The modified whisker zinc oxide or the modified silicon dioxide are prepared by the following steps:

[0036] Configure the mixed solvent according to the volume ratio of ethanol and water at 10:1, then mix according to the mass ratio of whisker zinc oxide or silicon dioxide to the mixed solvent at 1:30 to obtain a mixed solution...

Embodiment 2

[0039] This example proposes a fluorocarbon coating, which is prepared by mixing component A and component B Basonat HI-190 at a mass ratio of 10:0.9, and then putting it into a high-speed mixer at a speed of 800r / min and stirring for 20 minutes;

[0040] The component A, calculated in parts by weight, includes 20 parts of HLR-6 resin, 45 parts of HLR-670 resin, 10 parts of modified whisker zinc oxide, 5 parts of modified silicon dioxide, 0.5 parts of zinc molybdate, 6 parts of zinc borate, 0.4 part of zinc sulfate, 0.5 part of dispersant BYK161, 0.5 part of leveling agent BYK399, 0.1 part of defoamer BYK8801, 8 parts of solvent PMA, 4 parts of BAC.

[0041] The modified whisker zinc oxide or the modified silicon dioxide are prepared by the following steps:

[0042] Configure the mixed solvent according to the volume ratio of ethanol and water at 11:1, then mix according to the mass ratio of whisker zinc oxide or silicon dioxide to the mixed solvent at 1:35 to obtain a mixed s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com