Methane combustion catalyst as well as preparation method and application thereof

A methane combustion and catalyst technology, applied in the direction of combustion methods, catalyst carriers, chemical instruments and methods, etc., can solve the problems of easy deactivation of methane catalysts, and achieve low catalyst cost, good hydrothermal stability, and low precious metal content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] This embodiment provides a methane combustion catalyst, the methane combustion catalyst includes active components Pd and Al 2 o 3 Carrier, the active component Pd content in the methane combustion catalyst accounts for 1wt.%; the Al 2 o 3 The carrier consists of γ-Al 2 o 3 Prepared by calcination at 550°C for 5 hours, the γ-Al 2 o 3 The average particle size is 50 μm.

[0070] The preparation method of described methane combustion catalyst comprises the steps:

[0071] (1) Al 2 o 3 Add the carrier into water, then add palladium nitrate with a Pd content of 40wt.%, stir and mix at 25°C for 3 hours, and perform rotary evaporation after mixing to obtain a solid product. The palladium nitrate, Al 2 o 3 The mass ratio of carrier and water is 0.125:5:30;

[0072] (2) The solid product in step (1) was dried at 110° C. for 12 hours and calcined at 550° C. for 5 hours to obtain the methane combustion catalyst.

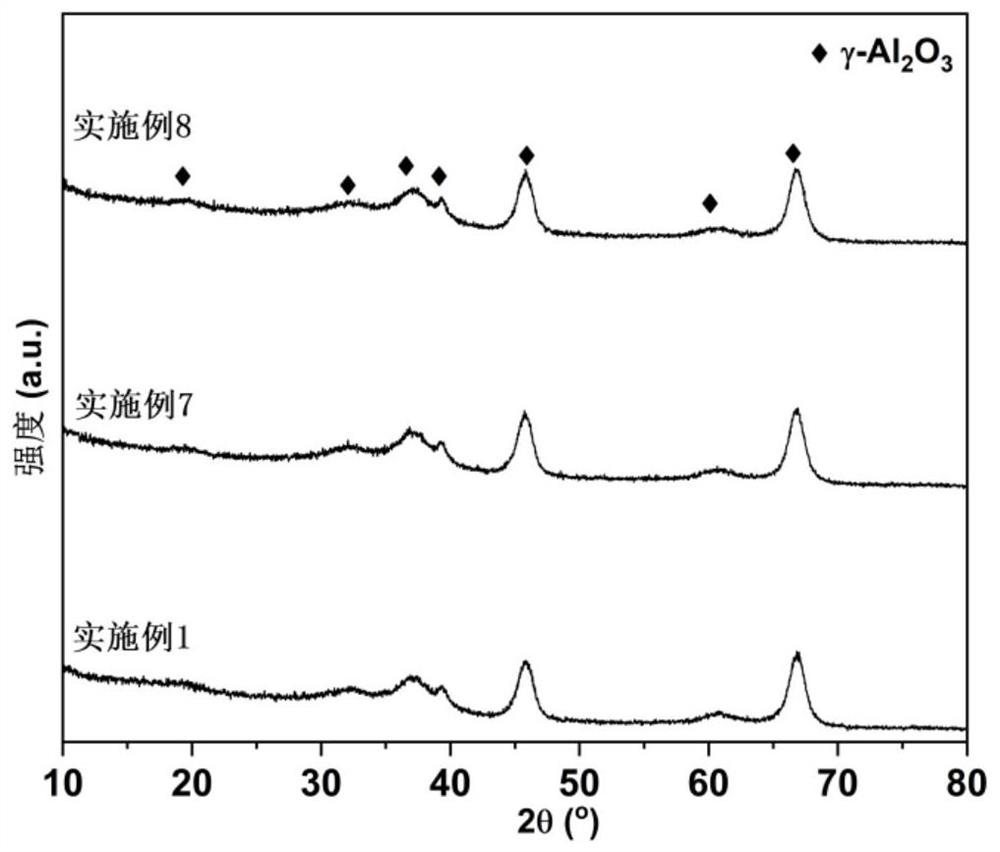

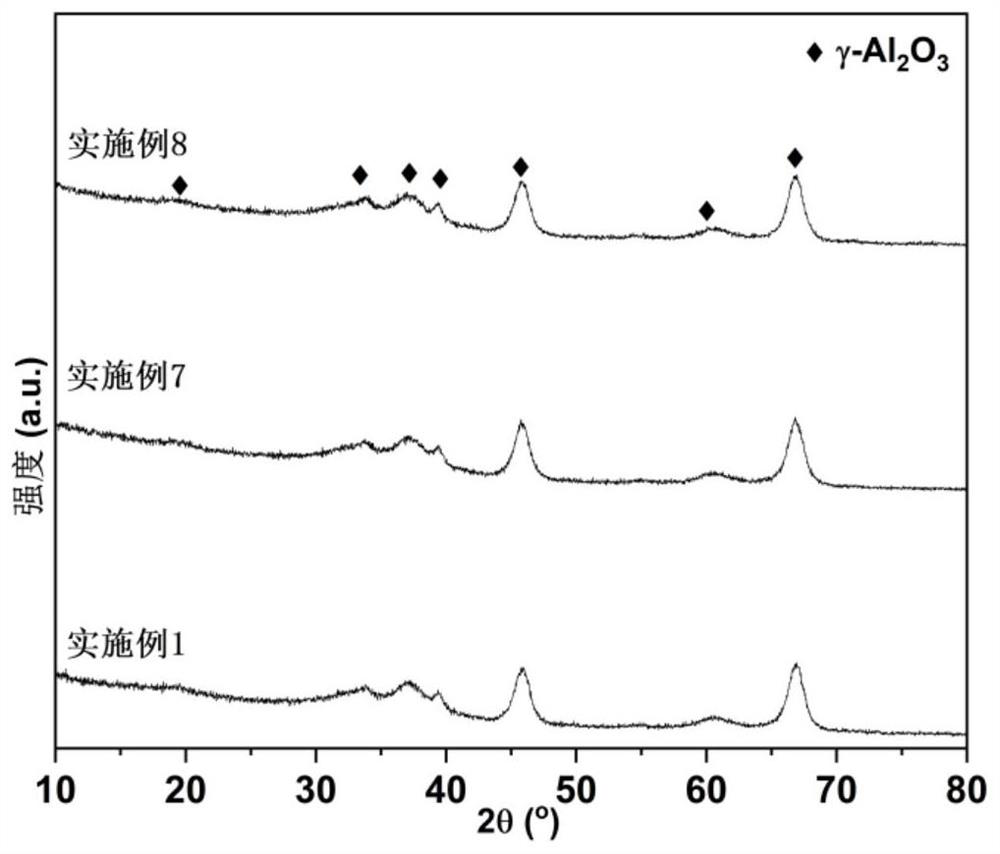

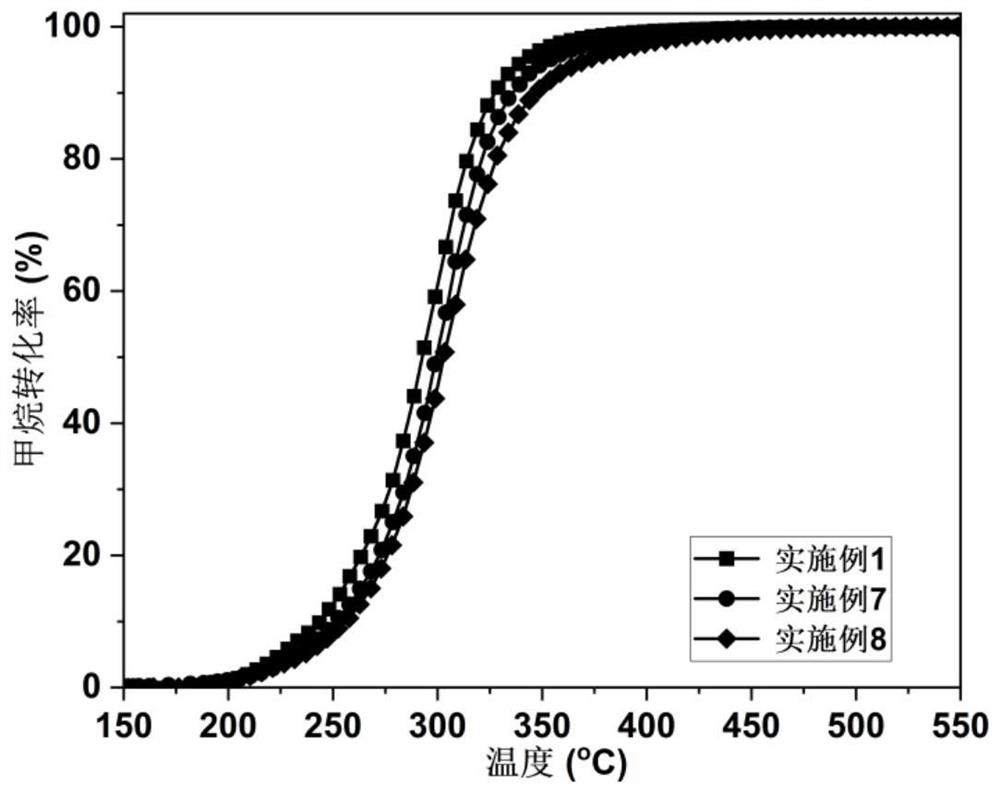

[0073] Al described in this example 2 o 3 The XRD pa...

Embodiment 2

[0075] This embodiment provides a methane combustion catalyst, the methane combustion catalyst includes active components Pd and Al 2 o 3carrier, the active component Pd content in the methane combustion catalyst accounts for 0.1wt.%; the Al 2 o 3 The carrier consists of γ-Al 2 o 3 Prepared by calcination at 450°C for 24 hours, the γ-Al 2 o 3 The average particle size is 75 μm.

[0076] The preparation method of described methane combustion catalyst comprises the steps:

[0077] (1) Al 2 o 3 Add the carrier into a mixed solvent of deionized water and ethanol, then add palladium chloride with a Pd content of 5wt.%, stir and mix at 20° C. for 24 hours, and perform rotary evaporation after mixing to obtain a solid product. The palladium chloride, Al 2 o 3 The mass ratio of carrier, deionized water and ethanol is 0.12:6:50:25;

[0078] (2) The solid product in step (1) is dried at 140° C. for 1 h and calcined at 900° C. for 1 h in sequence to obtain the methane combusti...

Embodiment 3

[0080] This embodiment provides a methane combustion catalyst, the methane combustion catalyst includes active components Pd and Al 2 o 3 carrier, the active component Pd content in the methane combustion catalyst accounts for 1.5wt.%; the Al 2 o 3 The carrier consists of γ-Al 2 o 3 Prepared by calcination at 1000°C for 1 hour, the γ-Al 2 o 3 The average particle size is 25 μm.

[0081] The preparation method of described methane combustion catalyst comprises the steps:

[0082] (1) Al 2 o 3 Add the carrier into a mixed solvent of deionized water and methanol, then add potassium chloropalladate with a Pd content of 26wt.%, stir and mix at 40°C for 2 hours, and perform rotary evaporation after mixing to obtain a solid product, the potassium chloropalladate, Al 2 o 3 The mass ratio of carrier, deionized water and methanol is 0.16:2.7:20:5;

[0083] (2) The solid product in step (1) was dried at 100° C. for 13 hours and calcined at 450° C. for 24 hours to obtain the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com